A kind of differential pressure cyclone separator and preparation method thereof

A technology of cyclone separator and pressure difference, which is applied in the direction of swirl devices and devices whose axial direction of swirl can be reversed, etc., can solve the problems such as difficult to realize effective collection of powder, reduce the size of axial space and improve collection rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

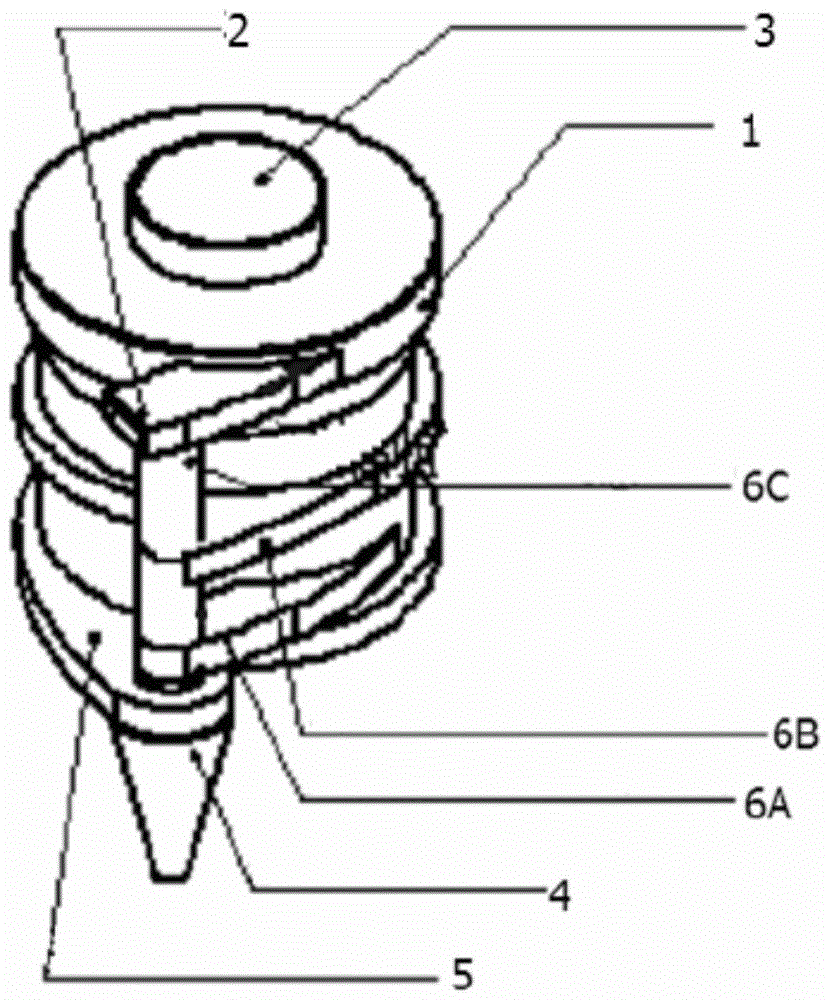

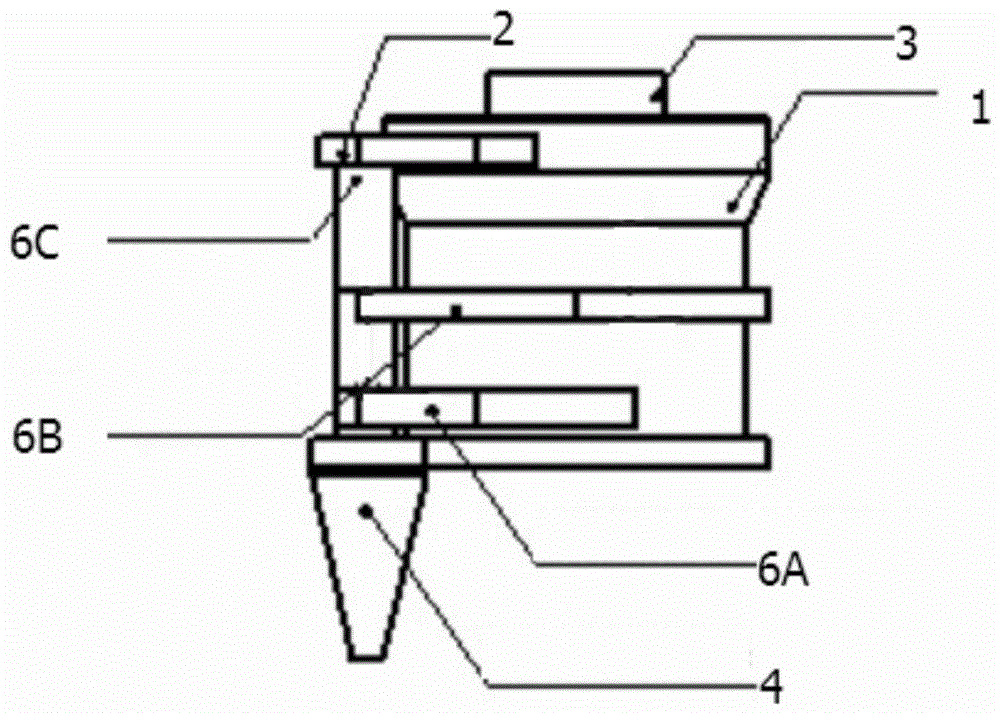

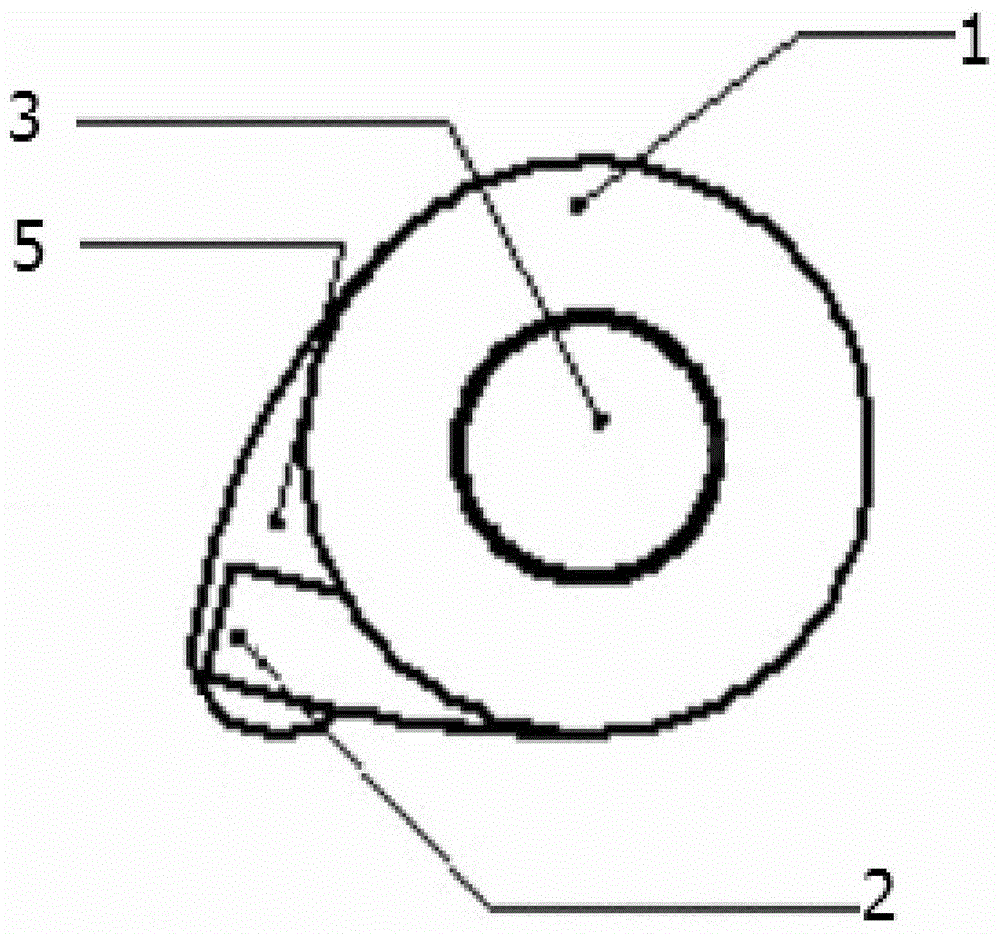

[0034] Embodiment 1: A kind of differential pressure cyclone separator

[0035] Refer to attached figure 1 -shown in 4, a kind of differential pressure cyclone separator comprises cyclone separator main cyclone body 1, cyclone separator main cyclone body air inlet 2, cyclone separator main cyclone body air outlet 3, cyclone separator auxiliary cyclone body 4, The air inlet 5 of the auxiliary cyclone body of the cyclone separator, the air outlet of the auxiliary cyclone body of the cyclone separator, and the air outlet of the auxiliary cyclone body is 6A.

[0036] The main cyclone body has a flat bottom, and a cyclone body air inlet 5 is arranged in a bypass at the bottom.

[0037] The conical bottom of the secondary cyclone body is opposite to the collection device.

Embodiment 2

[0038] Embodiment 2: A kind of differential pressure cyclone separator

[0039] Refer to attached figure 1 -shown in 4, a kind of differential pressure cyclone separator comprises cyclone separator main cyclone body 1, cyclone separator main cyclone body air inlet 2, cyclone separator main cyclone body air outlet 3, cyclone separator auxiliary cyclone body 4, The air inlet 5 of the auxiliary cyclone body of the cyclone separator, the air outlet of the auxiliary cyclone body of the cyclone separator, and the air outlet of the auxiliary cyclone body is 6B.

[0040] The main cyclone body has a flat bottom, and a cyclone body air inlet 5 is arranged in a bypass at the bottom.

[0041] The conical bottom of the secondary cyclone body is opposite to the collection device.

Embodiment 3

[0042] Embodiment 3: A kind of differential pressure cyclone separator

[0043] Refer to attached figure 1 -shown in 4, a kind of differential pressure cyclone separator comprises cyclone separator main cyclone body 1, cyclone separator main cyclone body air inlet 2, cyclone separator main cyclone body air outlet 3, cyclone separator auxiliary cyclone body 4, The air inlet 5 of the auxiliary cyclone body of the cyclone separator, the air outlet of the auxiliary cyclone body of the cyclone separator, and the air outlet of the auxiliary cyclone body is 6C.

[0044] The main cyclone body has a flat bottom, the bottom bypass is provided with a cyclone body air inlet 5, and the secondary cyclone body air inlet 5 is a tangential opening at the bottom bypass.

[0045] The conical bottom of the secondary cyclone body is opposite to the collection device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com