A large-diameter low-rigidity balanced flexible joint of a living flange self-locking joint

A flexible joint and large-diameter technology, applied in the direction of pipes/pipe joints/fittings, adjustable connections, passing components, etc., can solve problems such as insufficient displacement compensation performance, poor vibration and noise reduction effects, and complex joint structures, etc., to achieve Good vibration and noise barrier performance, easy installation, low stiffness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

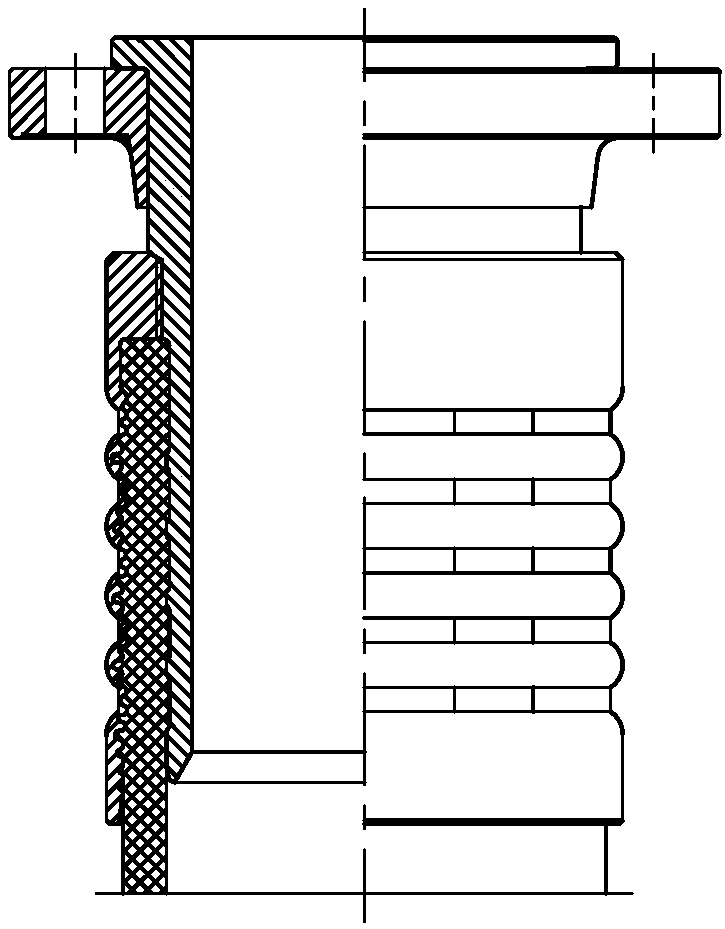

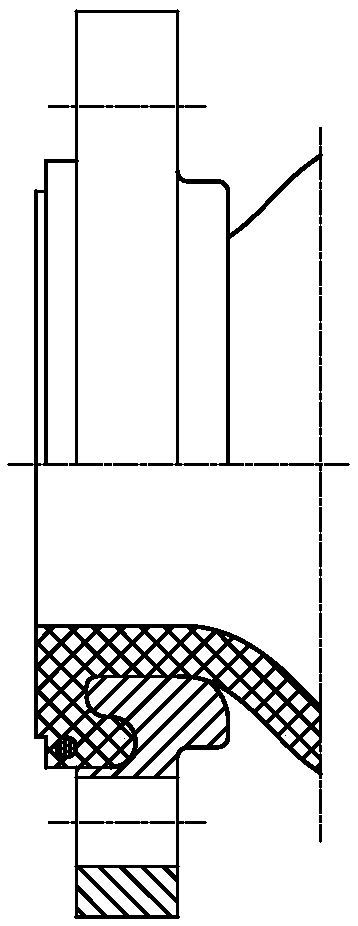

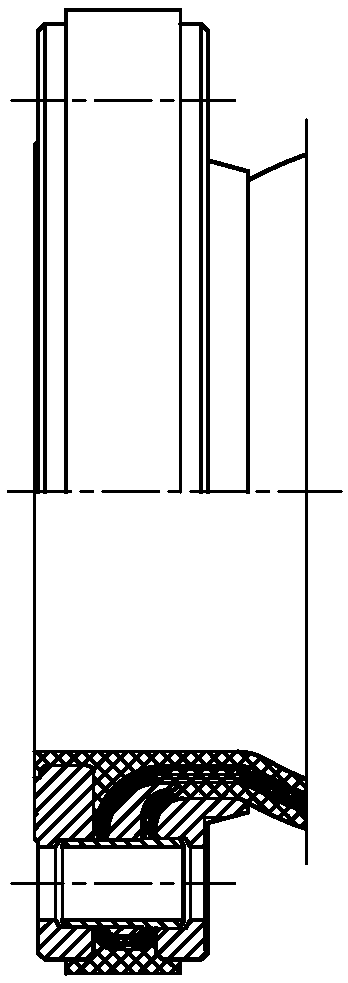

[0039] Participate in Figure 4-8 , a large-diameter low-rigidity balanced flexible joint with a living flange self-locking joint, including a flexible pipe body and a crimp joint, and the flexible pipe body 10 sequentially includes an inner rubber layer 2, a skeleton layer 3, and an outer rubber Layer 4, the two ends of the flexible pipe body 10 are respectively symmetrically provided with the crimping joints; the crimping joints are axial crimping joints, and the axial crimping joints are made of The outer pressure ring 5 and the inner pressure ring 6 arranged outside the framework layer 3 hold the turned over and turned-up framework layer 3 and form an integral body with the flexible pipe body 10 through vulcanization, and a looper is arranged outside the inner pressure ring 6 Flange1.

[0040] The skeleton layer 3 selects 2 to 6 layers of aramid cords to be spirally wound and intersected between two adjacent layers, the density of aramid cords is 9-10 pieces / cm, and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com