Tubular bus-bar fixing fitting

A technology for fixing fittings and pipe busbars, which is applied in the field of pipe busbar fittings, can solve problems such as limited sliding stroke, troublesome adjustment, galvanic corrosion, etc., and achieve the effects of flexible adjustment, improved flexibility, and enlarged adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

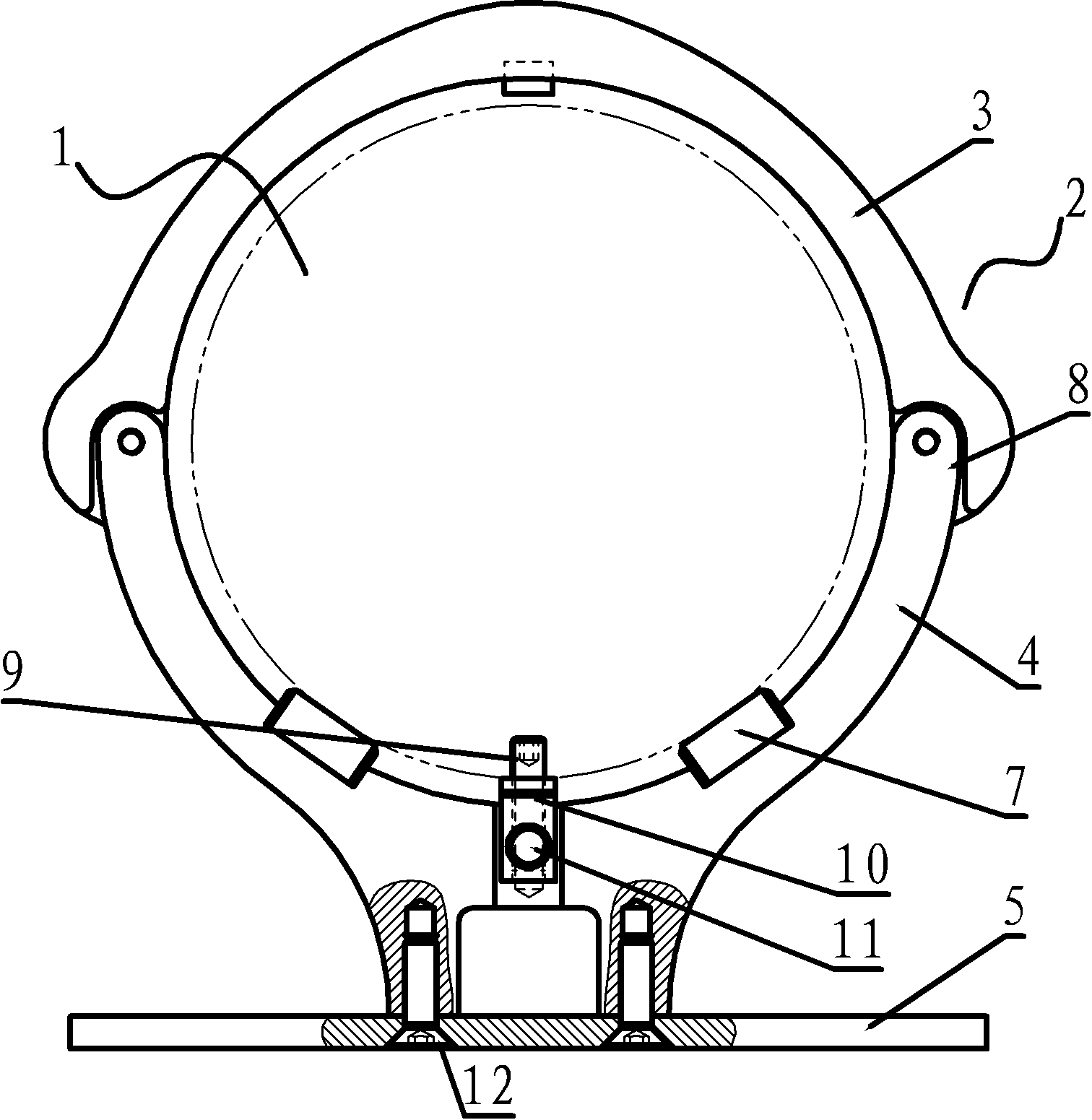

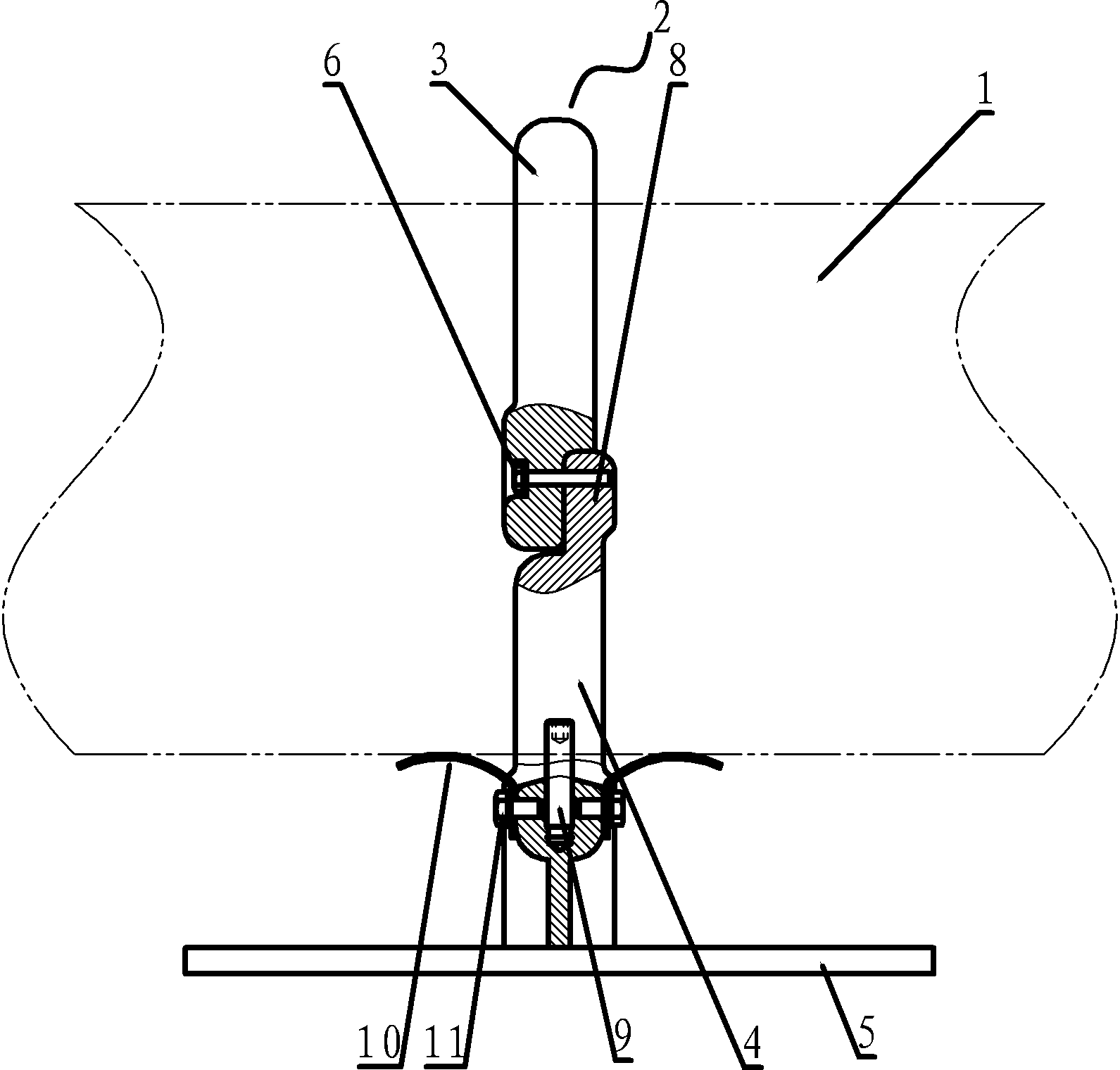

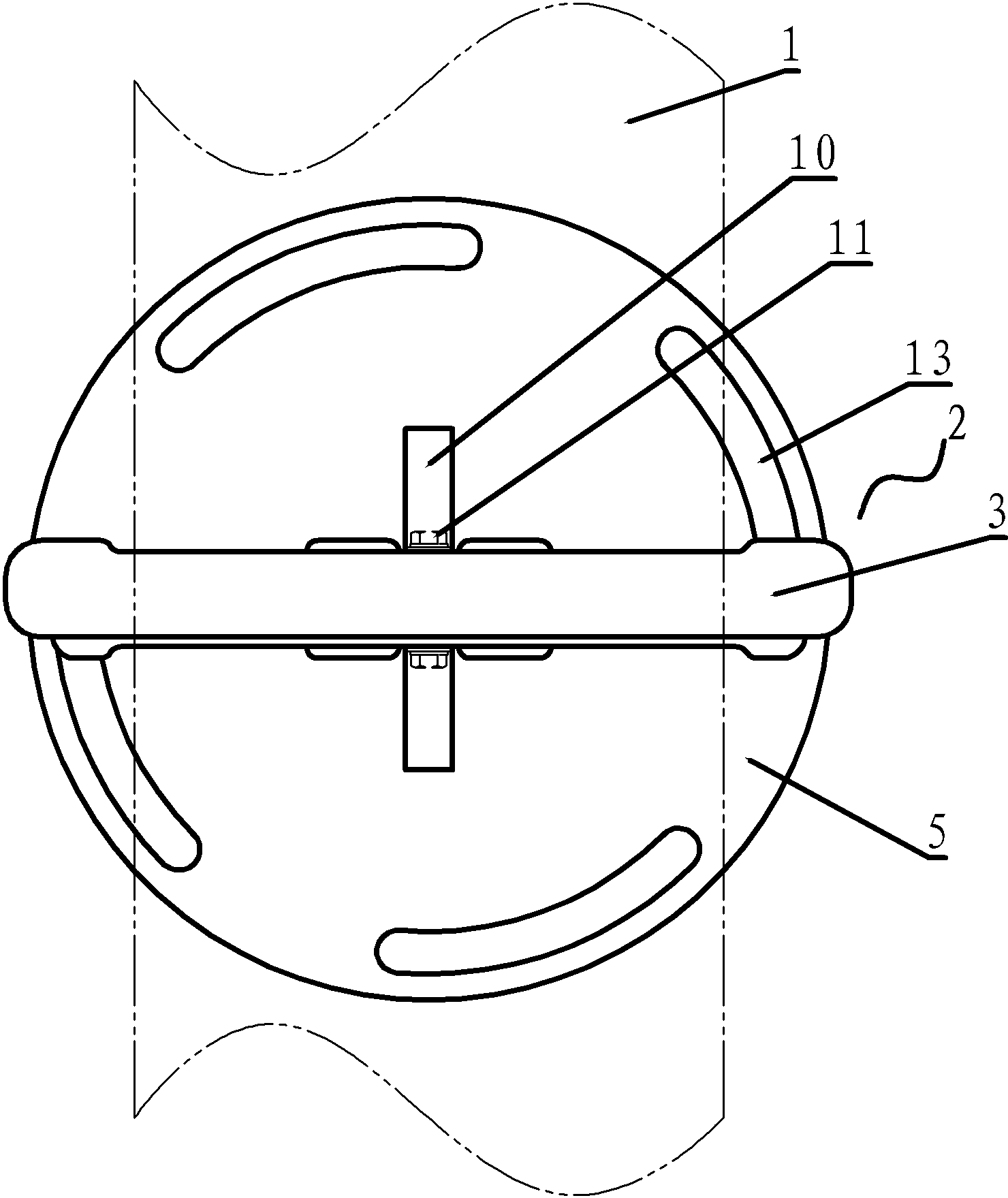

[0020] The embodiment of the pipe busbar fixing hardware of the present invention: as Figure 1 to Figure 3 As shown, the pipe bus bar fixing structure includes a pipe bus bar 1 and a fixing fitting 2 sleeved on the outer periphery of the pipe bus bar 1, and the fixing fitting 2 includes a buckle plate 3, a clamping seat 4 and a bottom plate 5 distributed sequentially from top to bottom, wherein the buckle The plate 3 is a semi-circular plate body, the concave part of the pinch plate 3 forms an upper concave surface buckled on the half of the outer peripheral surface of the pipe busbar 1, and the two ends of the pinch plate 3 are fixedly connected to the socket 4 by connecting screws 6. Above, the upper end of the card holder 4 is provided with a lower concave surface that is sunken downward, and the upper and lower concave surfaces are both semi-cylindrical, and the card holder 4 and the buckle plate 3 are surrounded by a positioning hole extending forward and backward connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com