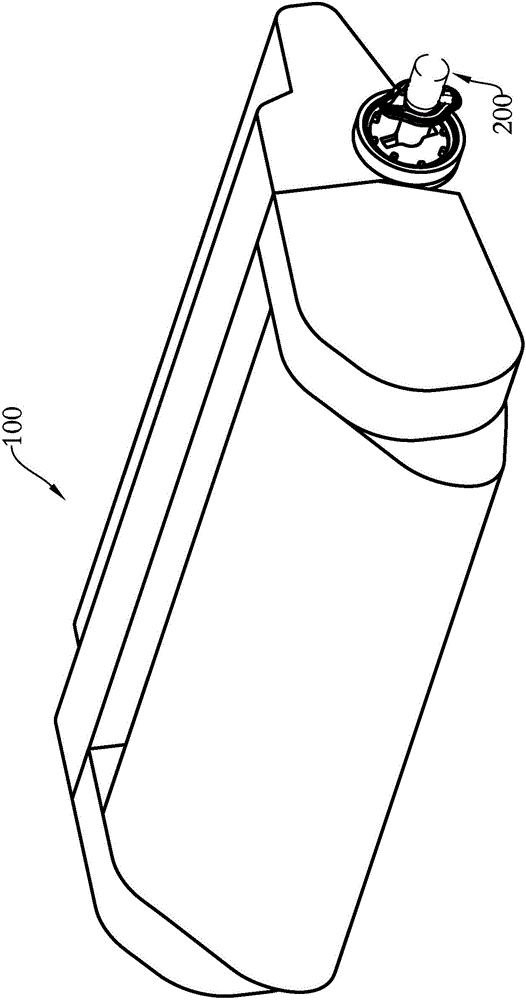

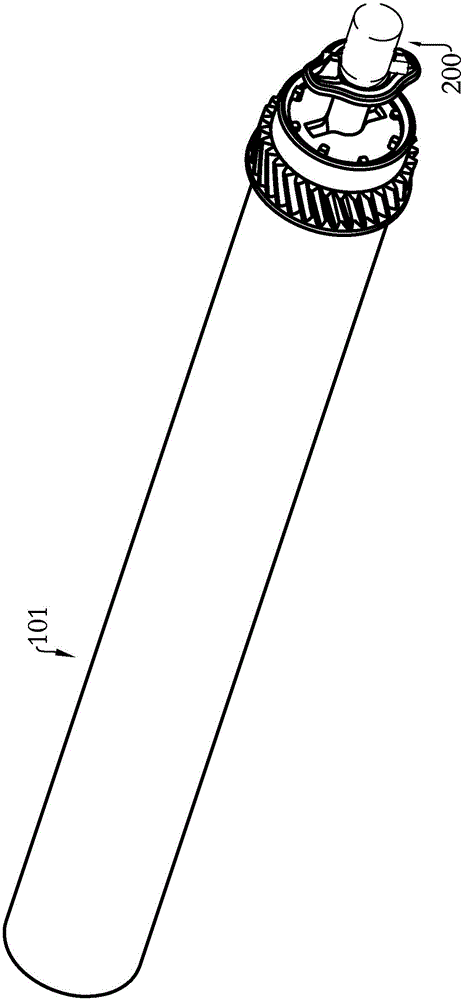

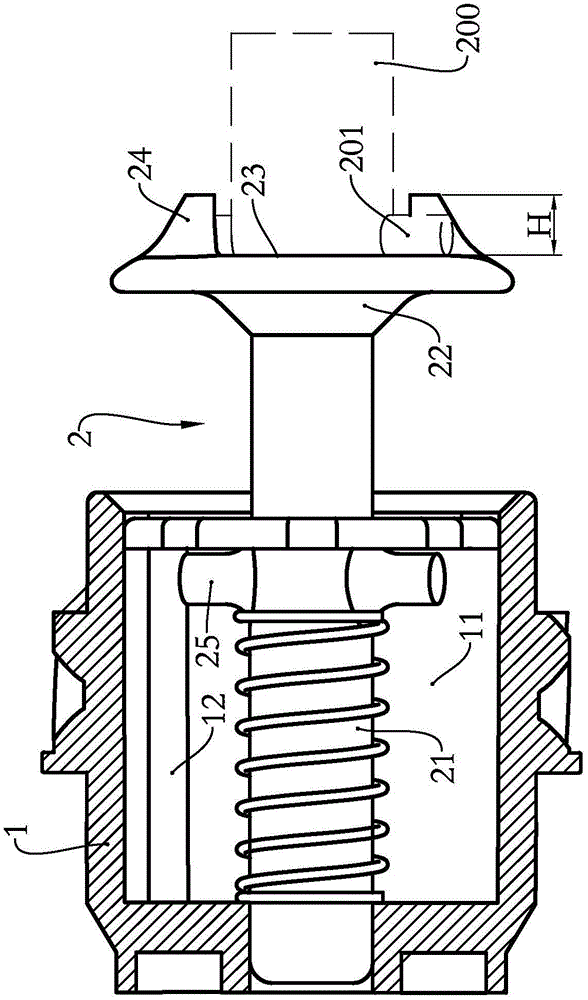

Torque receiving assembly, photosensitive drum, and process cartridge

A technology of components and laser printers, applied in optics, electrical recording, instruments, etc., can solve problems such as jamming, process box cannot be taken out smoothly, jamming, etc., and achieve the effect of avoiding "jamming" or jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] According to the torque receiving assembly of the present invention, the main structure of the photosensitive drum and the process cartridge constructed therefrom are the same as those of the prior art, and those skilled in the art can refer to the relevant technical materials of the prior art in the similar field and in conjunction with the background technology part of the description Introduction to understand the basic configuration of the torque receiving assembly, photosensitive drum and process cartridge of the present invention. In view of this, in the description of the specific embodiments of the torque receiving assembly, the photosensitive drum and the process cartridge of the present invention, the torque receiving assembly, the photosensitive drum and the process cartridge of the present invention will be related to the torque receiving assembly, the photosensitive drum and the process cartridge that can effectively prevent "jamming" or jamming when they are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com