Forging press

A mechanical and forging technology, applied in the field of forging machinery, can solve the problems affecting the working accuracy of the press, the complex clutch structure, the unbalanced force of the crankshaft, etc., to improve the transmission accuracy and service life, light weight and good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

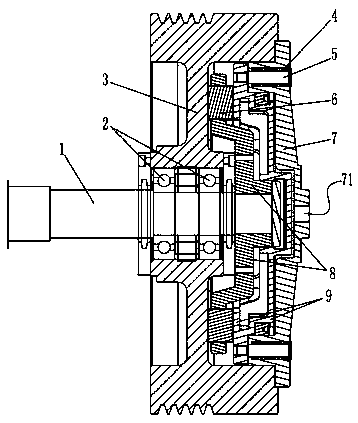

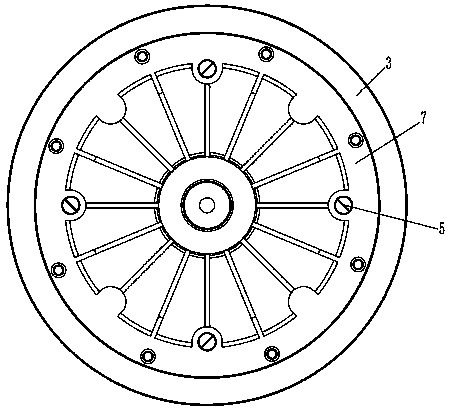

[0011] As shown in Figure 1 and Figure 2, a forging machine includes a crankshaft 1, a brake is installed on one end of the crankshaft 1, and a clutch is installed on the other end of the crankshaft 1, and the clutch includes a flywheel that is sleeved on the crankshaft 1 in turn 3. The driven shaft sleeve 8 and the driving disc 9, the flywheel 3 is installed on the crankshaft 1 through the bearing 2, the driven shaft sleeve 8 and the driving disc 9 are arranged in the cavity of the flywheel 3, and a housing 7 is fixedly connected to the outside of the cavity of the flywheel 3 , the driven bushing 8 is fixedly connected with the crankshaft 1, and the outer ring of the driven bushing 8 is inlaid with a plurality of movable friction blocks 6, and the driving disk 9 is sleeved on the crankshaft 1 and passed through a plurality of transmission pins 5 in a circumferential direction. It is connected to the housing 7 in a fixed and axially movable manner. The transmission pin 5 is sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com