Cold-storage plant and shelf assembly thereof

A refrigeration device and shelf technology, which is applied to household refrigeration devices, lighting and heating equipment, supports, etc., can solve the problems of inability to move horizontally and can not realize combined storage of food, and achieve combined storage and flexible distribution of refrigeration space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

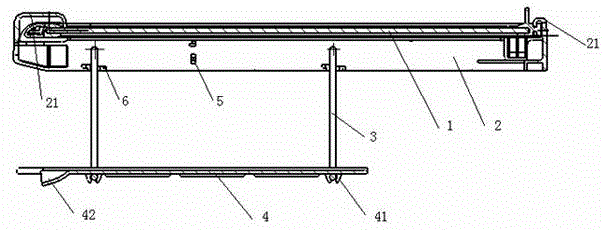

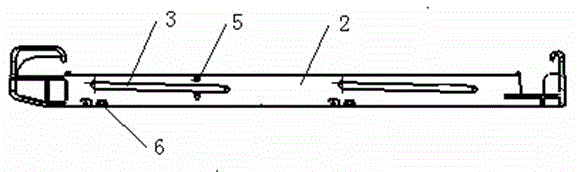

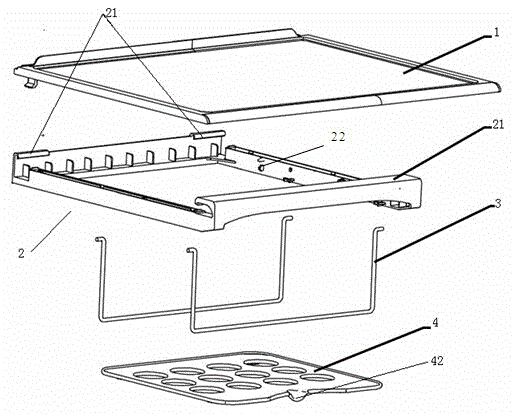

[0032] like Figure 1-4 As shown: this embodiment proposes a shelf assembly for a refrigerating device, including a shelf 1 , a moving bracket 2 , two sets of connecting rods 3 and a bracket 4 . Wherein, the mobile bracket 2 is mobile connected on the shelf 1, and one end of each group of connecting rods 3 is pivotally connected with the mobile bracket 2, and the other end is pivotally connected with the bracket 4, and is arranged on the mobile bracket 2. There is a retracted state restricting portion 5 for restricting the connecting rod 3 or the bracket 4 retracted to the bottom of the mobile bracket 2 . The connecting rod 3 and the bracket 4 can move along the shelf 1 under the action of the moving bracket 2 . When the bracket 4 is retracted to the bottom of the mobile bracket 2, the space between the adjacent two shelves 1 is not separated, it is a complete space, which can store items of larger volume and height; when the bracket 4 is opened , the bracket 4 becomes an au...

specific Embodiment 2

[0046] The difference between this embodiment and the specific embodiment 1 is that: this embodiment improves the structure of the mobile bracket 2, and the mobile bracket 2 is provided with a chute 23 communicating with the pivot shaft hole 22, when the bracket 4 is connected to After the rod 3 is retracted, the connecting rod 3 can slide along the chute 23, and limit the connecting rod 3 or the bracket 4 by the retracted state restricting part.

[0047] Specifically, such as Figure 6-8 As shown, the mobile support 2 is arranged below the shelf 1 and can move along the shelf 1. The mobile support 2 of this embodiment consists of a front support, a rear support, a left support and a right support. Wherein, the front bracket and the rear bracket of the mobile bracket 2 are provided with clamping devices, and the mobile bracket 2 is clamped on the shelf 1 through the clamping device and moves along the shelf 1 . In this embodiment, the clipping device is described as the under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com