Wave suppressor for railroad tanker

A technology for tank cars and railways, which is applied in the field of anti-wave devices for railway tank cars, which can solve problems such as high cost, large longitudinal impact of tank car heads, and unfavorable driving safety, so as to improve service life, overcome uneven force, and ensure driving safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

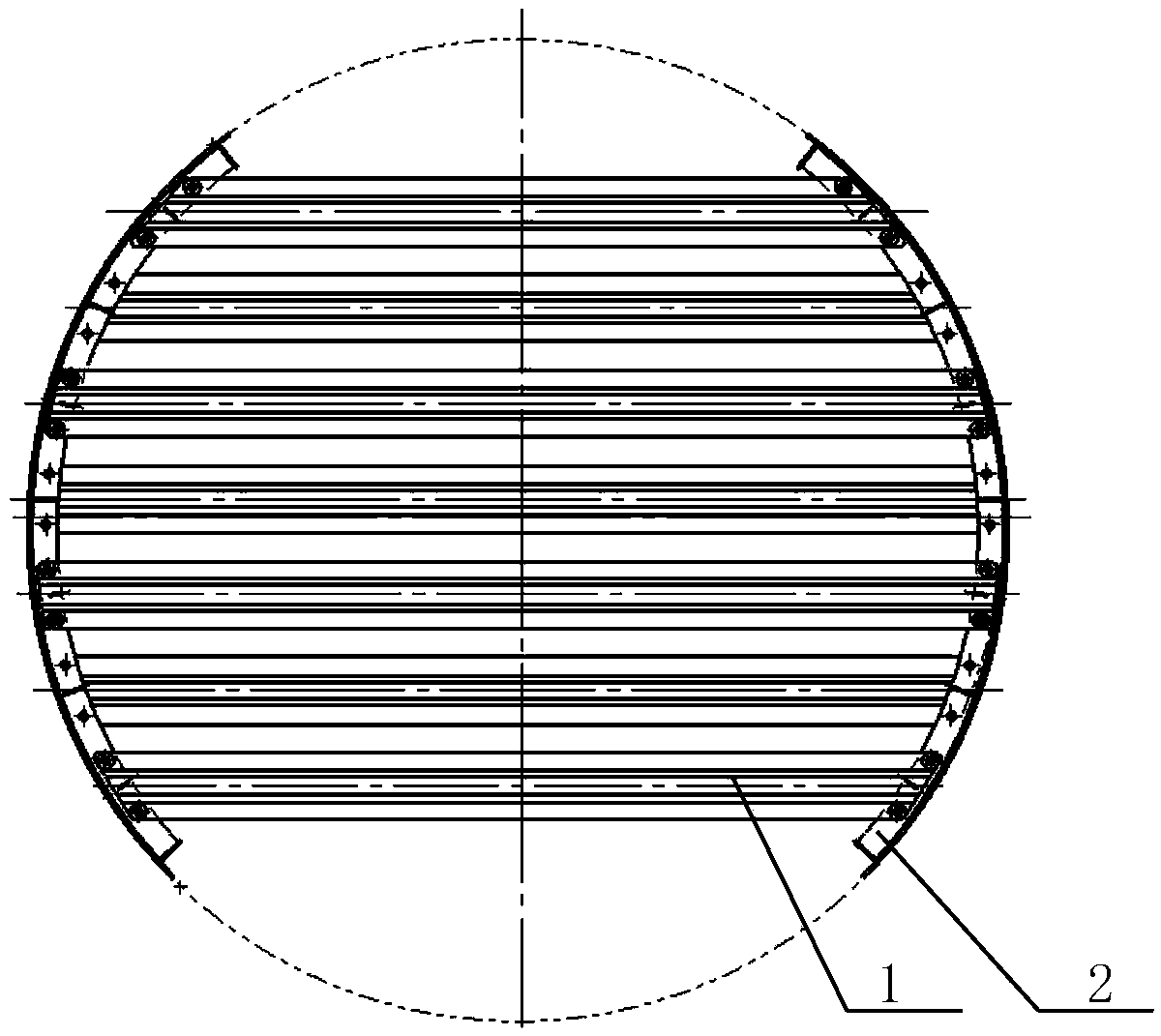

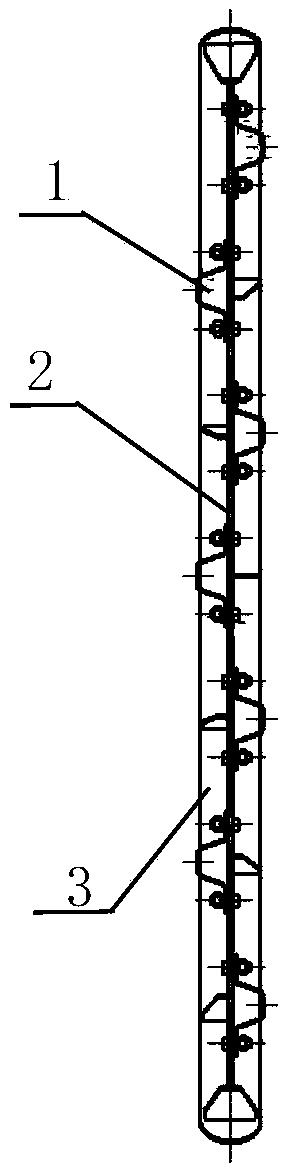

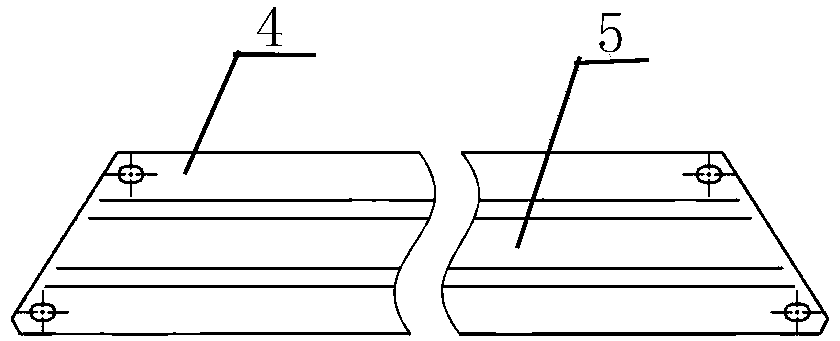

[0020] see Figure 1 to Figure 5 , the present invention includes a wave-proof plate 1 and a mounting seat 2, the mounting seat 2 is fixed on the inner wall of the tanker, and the wave-proof plate 1 is fixed on the mounting seat 2. Its key technology is as figure 2 As shown, the anti-wave plate 1 is evenly spaced and fixed on both sides of the mounting base 2 in a fence shape, as shown in image 3 , Figure 4 As shown, the anti-wave plate 1 is integrally extruded by a strip-shaped steel plate. The middle part of the strip-shaped steel plate protrudes along the length direction to form a hat top 5, and the bottom edge of the hat top 5 is flanked by brims 4, forming a hat-shaped structure.

[0021] Depend on figure 2 It can be seen that the cap top 5 of the anti-wave plate is arranged in opposite directions on both sides of the mounting base 2 . The hat-shaped structure and the arrangement on the mounting seat conform to the motion law of fluid mechanics, and can effective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com