Single-connection light energy-saving wallboard

A single-link, lightweight technology used in wall panels. It can solve problems such as unfavorable energy saving, potential safety hazards, and increased construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

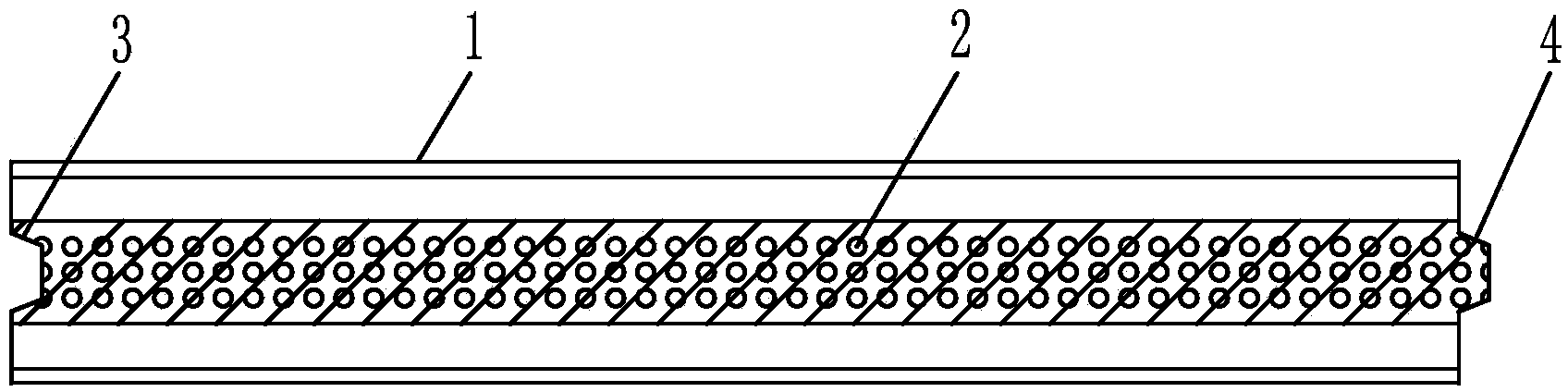

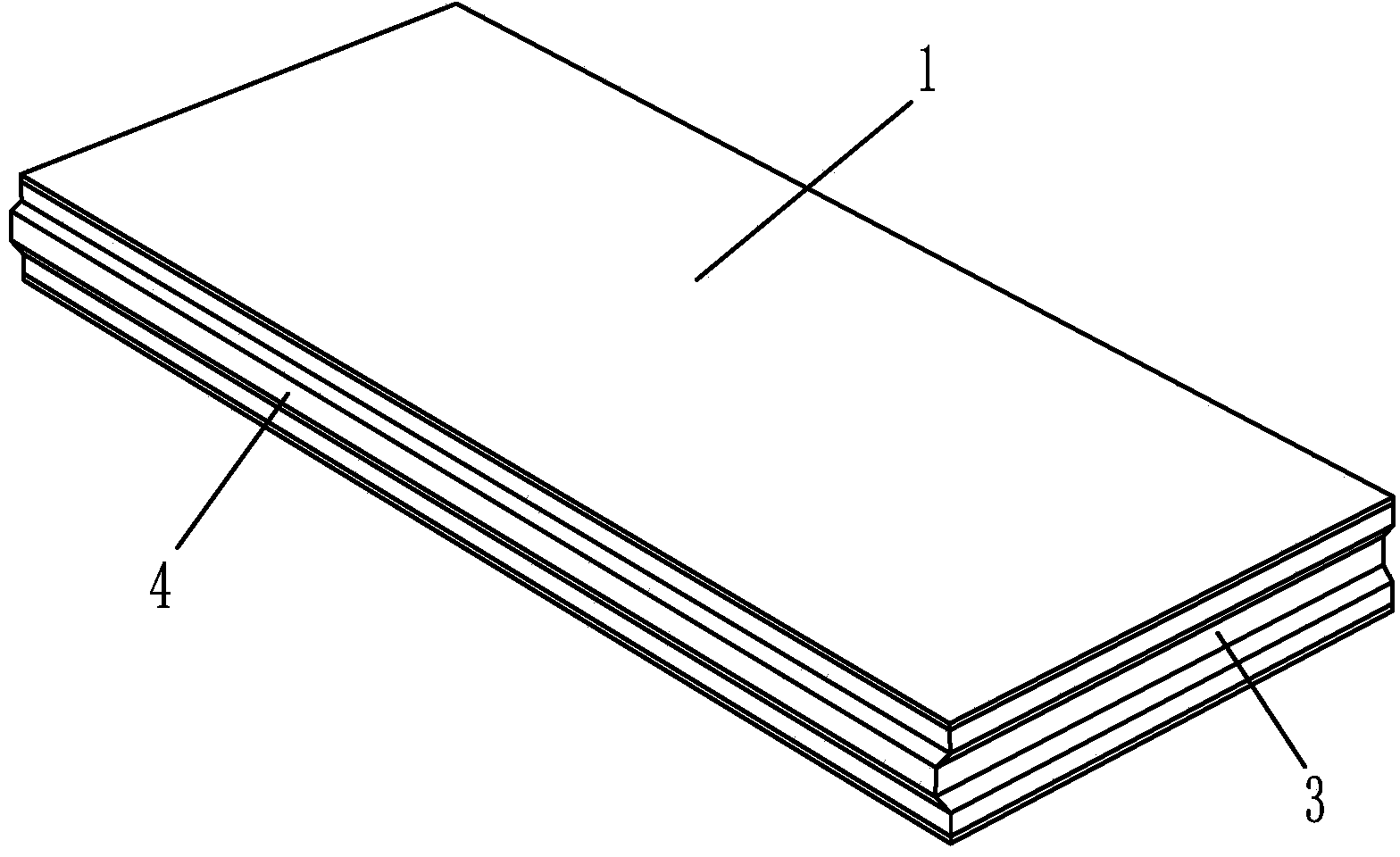

[0010] Such as figure 1 , 2 As shown, the single-connection lightweight energy-saving wallboard of the present invention includes a body 1, the body 1 is a plate-shaped cuboid structure, and a layer of foam layer 2 is arranged in the middle of the body 1, and one of the long and short sides of the body 1 The sides are provided with elongated grooves 3 respectively, and the side of the other long side is provided with cuboid protrusions 4 corresponding to the grooves 3 .

[0011] There is a layer of foam layer 2 in the middle of the body, which not only reduces the weight of the wallboard, but also the foam particles have a certain heat insulation effect, thereby increasing the heat insulation effect of the wall, so it is beneficial to energy saving; 4 is spliced and connected with the groove 3, which improves the connection stability between the wall panels, thereby ensuring the firmness of the wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com