Prestressed bellows dredge and method of use

A prestressed and corrugated pipe technology, applied in construction, building structure, construction material processing and other directions, can solve the problems of blockage of pore diameter and smaller diameter, and achieve the effect of good flexibility, convenient assembly and disassembly, and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

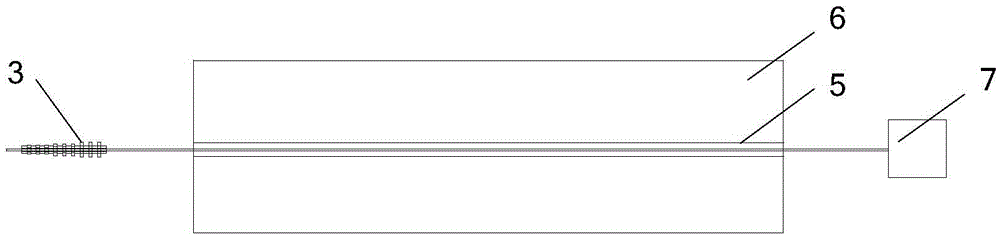

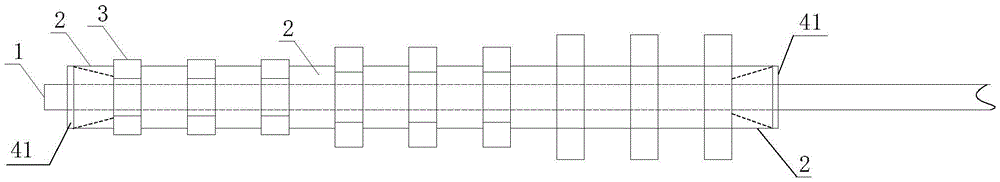

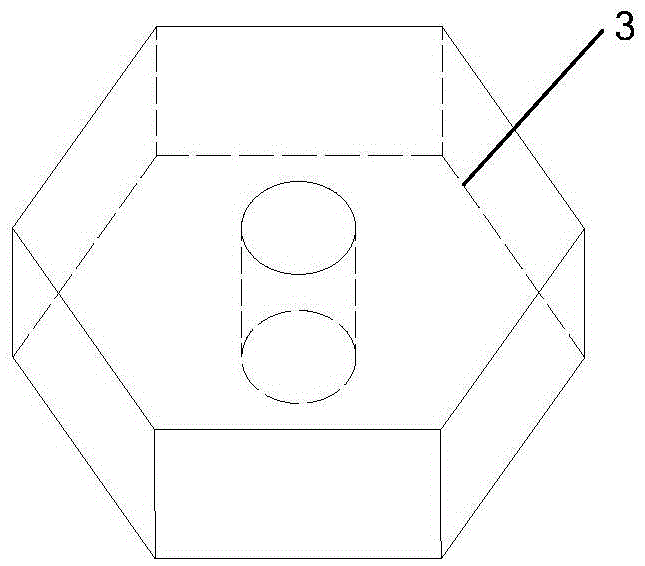

[0035] The central idea of the prestressed corrugated pipe dredger and its use method of the present invention is that by setting a traction rope, several partitions and several cutting pieces, the partitions and the cutting pieces are alternately set on the traction rope and positioned at The partitions at the beginning and the end are respectively fixedly connected with the traction rope, and the cutting pieces include at least two sizes and specifications, and the cutting pieces are arranged from small to large along the traction rope, which can reduce the amount of concrete accumulated in the channel of the prestressed corrugated pipe. The slurry is cut and dispersed and brought out of the pipe smoothly to solve the problem of channel blockage and aperture reduction caused by slurry leakage in the channel of the prestressed corrugated tube, and to ensure that the traction rope can be stretched in the prestressed corrugated tube in the later stage to apply prestress .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com