Compact stainless steel wire mesh cleaning method of fluidized bed

A technology of fluidized bed and stainless steel mesh, which is applied in the field of hot metal desulfurization, can solve the problems of incomplete cleaning with high-pressure water, and achieve the effect of fast drying and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

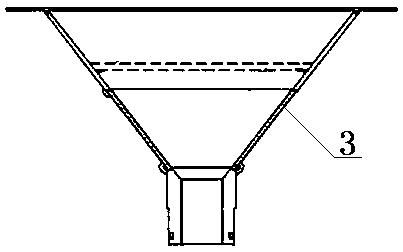

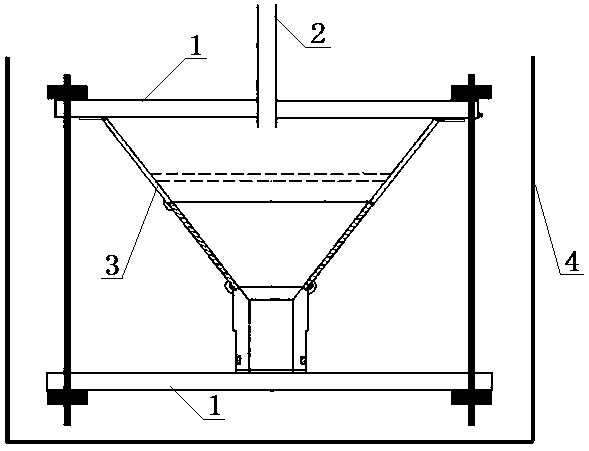

[0012] A method for cleaning a dense stainless steel net in a fluidized bed. Two upper and lower blind plates 1 are made, and an air inlet pipe 2 is welded on one side of the blind plate. Two blind plates 1 are used to cover the large mouth end and the small mouth of a cone fluidized bed 3 At the end, two blind plates 1 clamp the cone fluidized bed 3 in the middle, holes are opened on the edge of the blind plates 1, and the through holes are used for bolts to pass through, and the two blind plates 1 are fixed tightly with bolts and nuts. Prepare a water tank 4 capable of accommodating the combination of the blind plate 1 and the cone fluidized bed 3 . Put the whole combined blind plate 1 and cone fluidized bed 3 into the water tank 4, add water to submerge the cone fluidized bed 3, then add 1-2L dilute hydrochloric acid with a mass concentration of 10-13%, soak for 10 -12 hours, enter the compressed air from the inlet pipe 2, the pressure of the compressed air is 0.4MPa-0.5Mpa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com