Hydraulic multi-way valves for agricultural machinery

A technology for agricultural machinery and multi-way valves, applied in the field of multi-way valves, can solve the problems of not setting hydraulic locks, oil leakage, and worn valve holes, so as to increase floating function, improve work reliability, and prevent oil leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

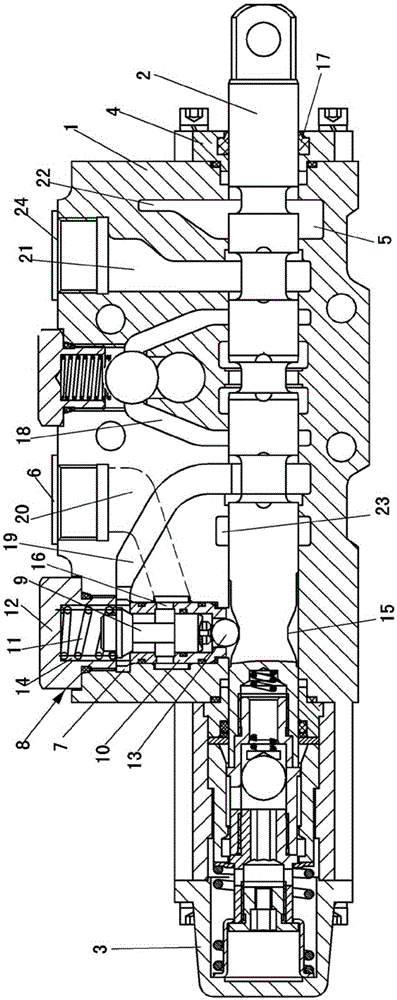

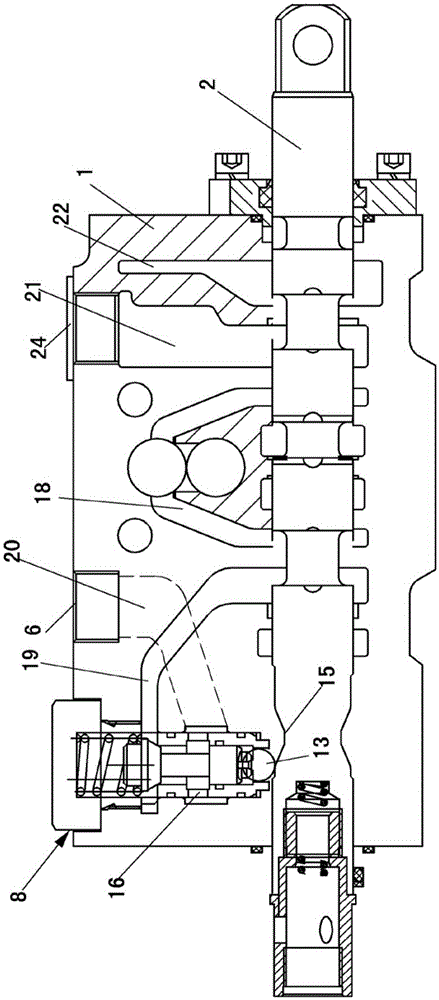

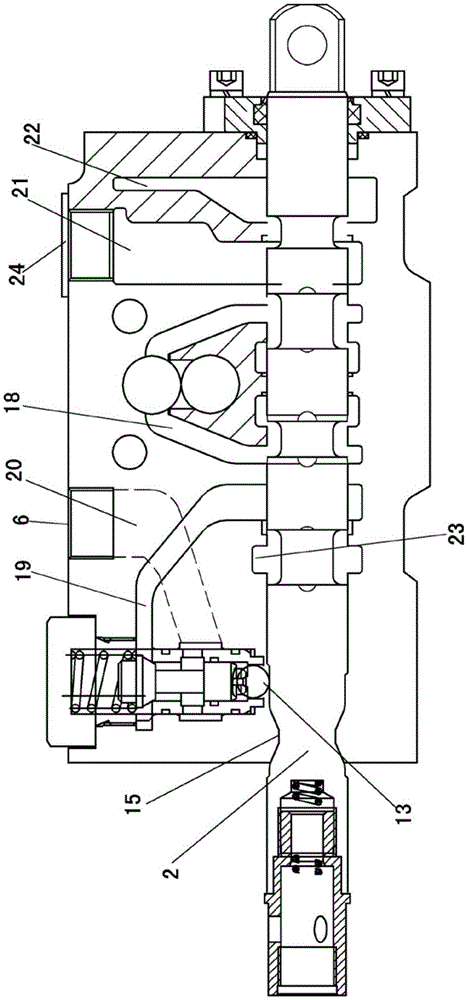

[0026] See attached figure 1 ~ attached Figure 4 , the hydraulic multi-way valve for agricultural machinery of the present invention includes a valve body 1, a valve stem 2, a rear cover 3 and a bracket 4; a valve cavity 5 is arranged in the valve body 1, and the valve stem 2 is inserted into the In the valve cavity 5 and the valve stem 2 protrudes outside the valve body 1 at the right end, the bracket 4 is sleeved on the valve stem 2 and is located on the right end surface of the valve body 1; The rear cover 3 is located at the left end of the valve body 1; the valve body 1 is provided with a working oil port A6 and a hydraulic lock cavity 7, and the hydraulic lock cavity 7 and the working oil port A6 are connected through the first The three oil passages 20 are connected, and the hydraulic lock chamber 7 and the valve chamber 5 are connected through the second oil passage 19; a hydraulic lock 8 is arranged in the hydraulic lock chamber 7;

[0027] The hydraulic lock 8 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com