An AGV automatic lifting mechanism self-locking device

A self-locking device and automatic lifting technology, applied in the directions of transmission parts, mechanical equipment, transmission components, etc., can solve the problems of not landing, slipping, etc., and achieve the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

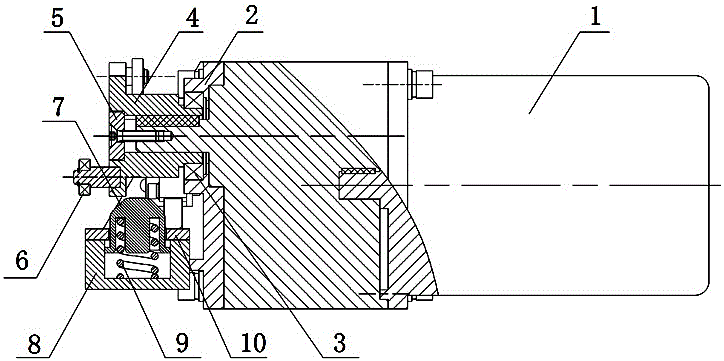

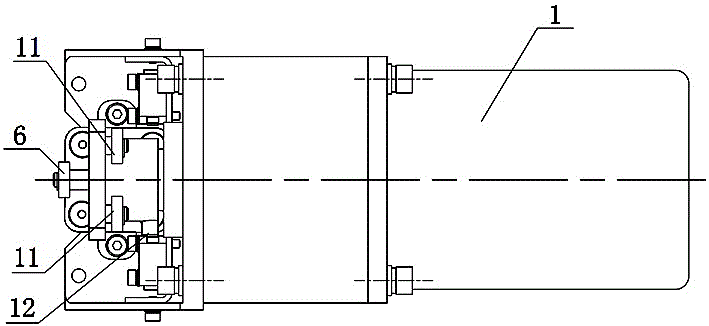

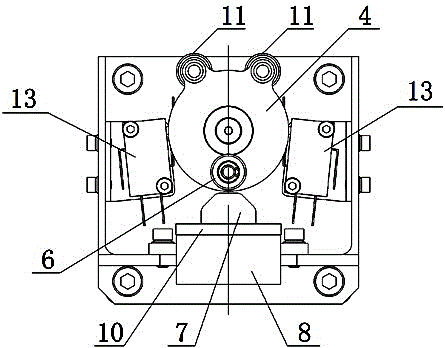

[0017] Such as figure 1 , figure 2 and image 3 As shown, a self-locking device of an AGV automatic lifting mechanism, which includes a geared motor 1, a lifting bearing 3, a turntable 4, a telescopic pin 7, a self-locking spring 9 and a limit bearing 11, and the end face of the body on the output side of the geared motor 1 The lifting bearing seat 2 is installed on the top, the output shaft of the reduction motor 1 passes through the lifting bearing seat 2, and a turntable 4 is installed in conjunction with it, and a lifting bearing 3 is installed between the turntable 4 and the lifting bearing seat 2, and the turntable 4 is far away from the reduction motor 1- An eccentric bearing 6 is installed on the end surface of the side, two limit bearings 11 are installed on the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com