A Bottom Multilayer Plasma Ignition Device

A plasma and ignition device technology, which is applied to weapon accessories, blasting cylinders, offensive equipment, etc., can solve the problems of broken propellant, small initial ignition area of propellant, and high jet velocity, so as to increase the initial combustion area and achieve Ignition consistency, effect of controlling injection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

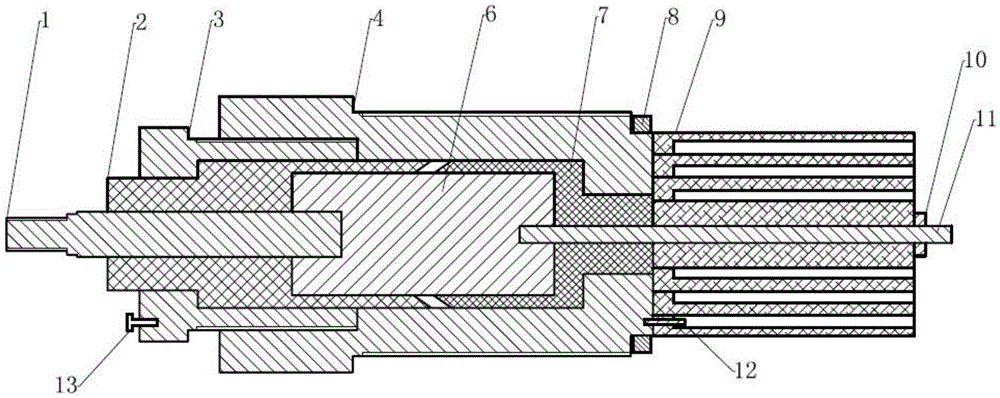

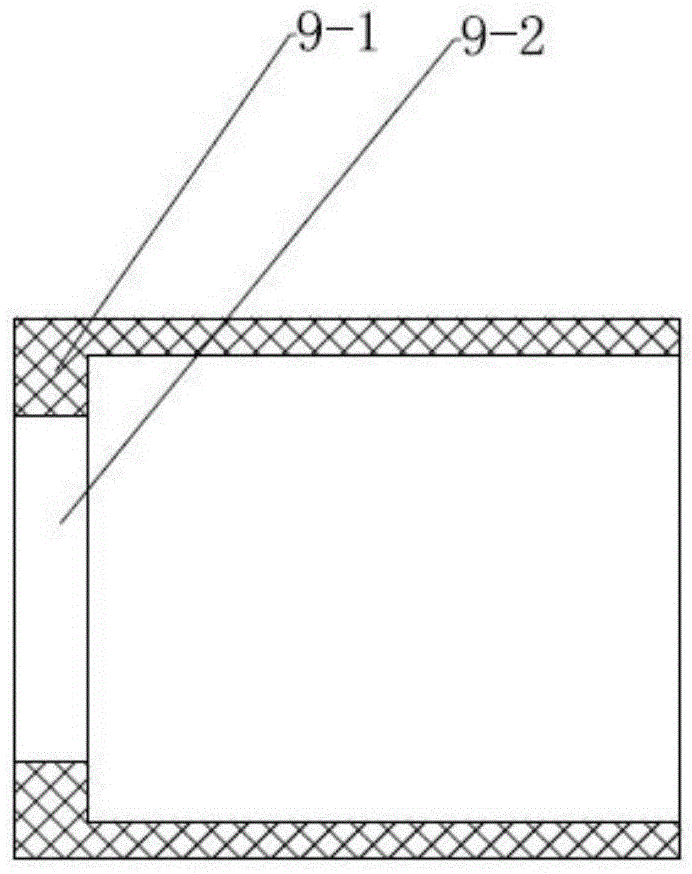

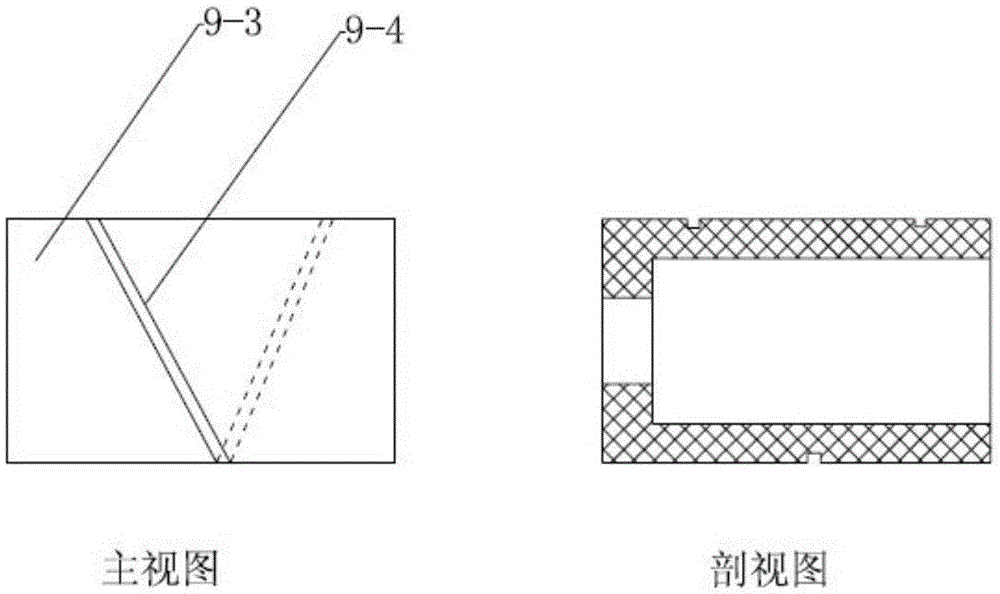

[0020] Such as figure 1 As shown, the preferred embodiment of the bottom multilayer plasma ignition device of the present invention includes an external ignition electrode rod 1, an outer end of an insulating sealing sleeve 2, an insulating sleeve compression screw plug 3, a screw plug body 4, an electrode compression block 6, The inner end of the insulating sealing sleeve 7, the sealing gasket 8, the cylindrical multi-layer plasma generator 9, the nut 10, the positive ignition needle 11, the negative ignition needle 12, and the negative terminal bolt 13. The ignition electrode rod 1 is a steel cylinder, one end of which is a necked external thread, which is connected to the ignition electrode by means of bolt fastening, and the external thread at the other end is connected to the electrode pressing block 6 . The sealed outer end 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com