Microporous fabric garment capable of achieving humidification function for breathing

A microporous and fabric technology, applied in clothing, clothing, protective clothing, etc., can solve the problems of no moisture absorption and quick drying performance, no antibacterial function, etc., and achieve the effect of strong moisture absorption and quick drying performance, permanent antibacterial function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

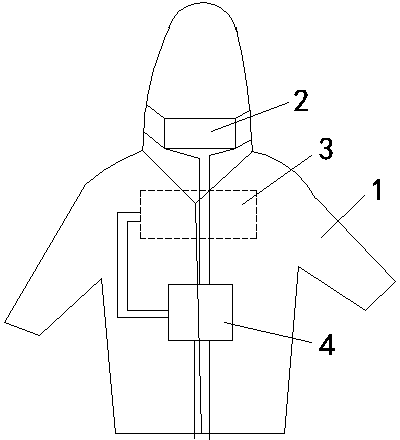

[0015] see figure 1 , a microporous fabric garment capable of humidifying breathing according to the present invention, comprising a garment body 1, a mouth mask 2 is provided on the neckline of the garment body 1, an ultrasonic humidifier 3 is provided on the back of the garment body 1, and the The front body of the garment body 1 is provided with an air storage box 4, and the mask 2, the ultrasonic humidifier 3 and the air storage box 4 are all connected by conduits.

[0016] The garment body is made of a fabric, the fabric includes a warp and a weft, any one of the warp and the weft is a microporous polyester fiber, and the microporous polyester fiber includes a microporous polyester fiber matrix, Several micropores are arranged on the microporous polyester fiber matrix.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com