A lift-up carton unpacking device with controllable impact force and its control method

An impact force and lift-up technology, applied in the field of industrial production, can solve the problem of large impact force when unpacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

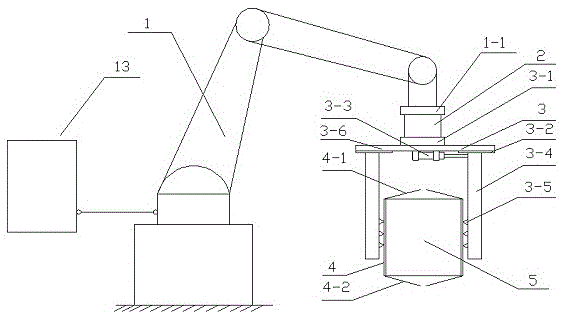

[0020] Example 1: Reference figure 1 The unboxing principle of the lift-up carton unboxing device with controllable impact force is shown. The lift-up carton unboxing device with controllable impact force includes a force sensor (2), a mechanical clamping device (3), a pneumatic control The device, and the controller (13), the force sensor (2) is installed between the end flange (1-1) on the industrial robot (1) and the connecting flange (3-1) of the mechanical clamping device, the material (5) Packed in a carton (4), and the carton (4) is clamped by a mechanical clamping device (3). The mechanical clamping device (3) is driven by the clamping cylinder (3-3) to drive the clamping arm (3-4) to move; the clamping arm (3-4) is mounted on the linear guide rail (3-2), so that the The clamping arm (3-4) can perform linear reciprocating motion on the linear guide rail (3-2); the clamping arm (3-4) is equipped with a steel needle (3-5), in order to ensure that during the unboxing pro...

Embodiment 2

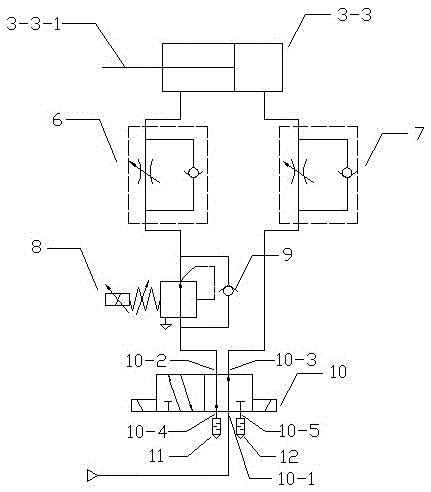

[0021] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the special features are as follows: refer to figure 2, which shows the pneumatic principle diagram for the above-mentioned mechanical clamping device, the external air source is connected to the air inlet (10-1) of the double electronically controlled 5 / 2-way reversing valve (10), and the double electronically controlled An air outlet (10-2) of the two-position five-way reversing valve (10) is connected to the pneumatic pressure proportional valve (8), the speed control valve (6), and the rod cavity of the clamping cylinder (3-3) in sequence, The pneumatic pressure proportional valve (8) is connected in parallel with a one-way valve (9); the other air outlet (10-3) of the double electronically controlled two-position five-way reversing valve (10) is connected to the speed control valve ( 7) The rodless cavities of the clamping cylinder (3-3) are connected in sequence; the exhaust port (10-4) and ...

Embodiment 3

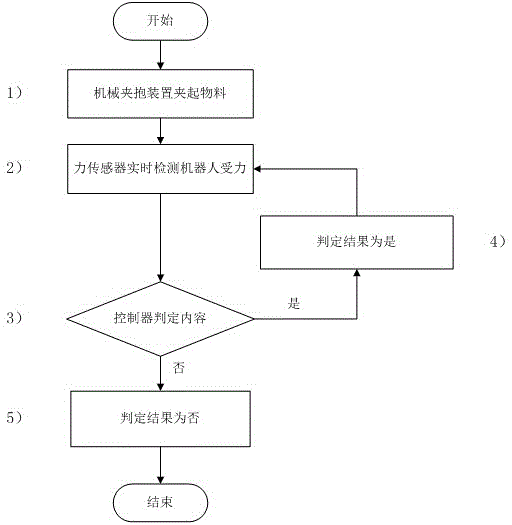

[0022] Example 3: Reference image 3 , which shows the specific steps of a control method of a lift-up carton unboxing device with controllable impact force of the present invention: Step 1): The mechanical clamping device (3) removes the carton (4) together with the materials ( 5) Clamp and lift to a certain height. Step 2): The force sensor (2) detects in real time the downward pulling force received by the robot (1), including the gravity of the mechanical clamping device (3) itself, the gravity of the carton (4), and the material (5) relative to the carton ( 4) The resulting downward pull force. The controller (13) deducts the force detected by the force sensor (2) from the gravity of the mechanical clamping device (3) itself and the gravity of the carton (4) to obtain the direction of the material (5) relative to the carton (4). Pull down force. Step 3): The controller (13) determines whether the material (5) is relative to the carton (4) according to whether the downw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com