Electrical installation tool for overhead line fault indicators

A technology for fault indicators and installation tools, which can be applied to fault locations, instruments, and measuring electronics. It can solve the problems of compression springs deviating from the center of the V-shaped slot, smashing operators, and errors in the return of support frame pull pins, etc., to achieve Easy to return, improve installation success rate, and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

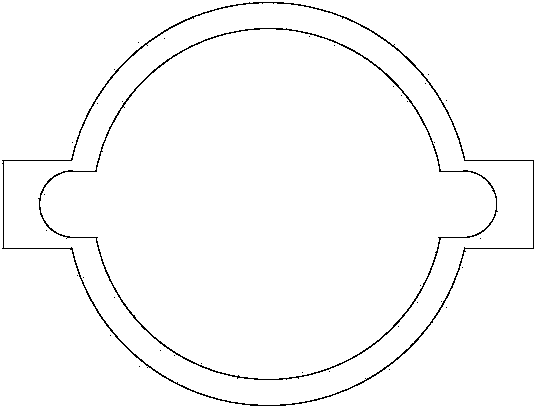

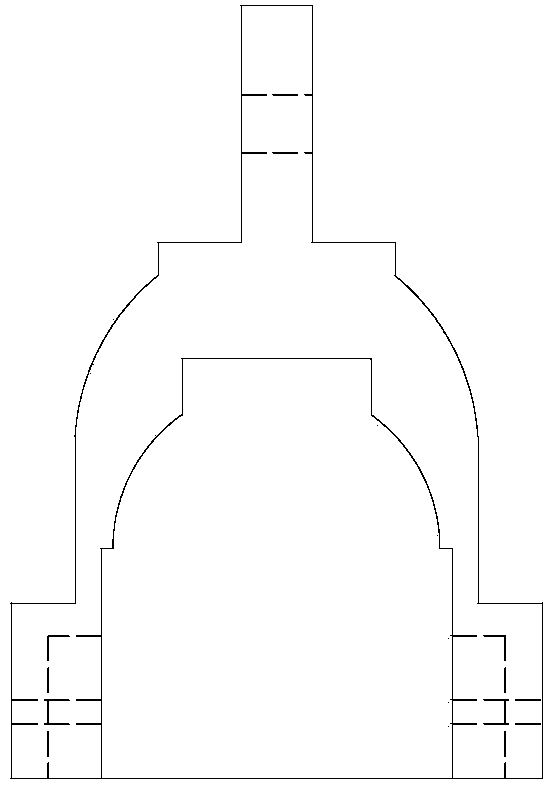

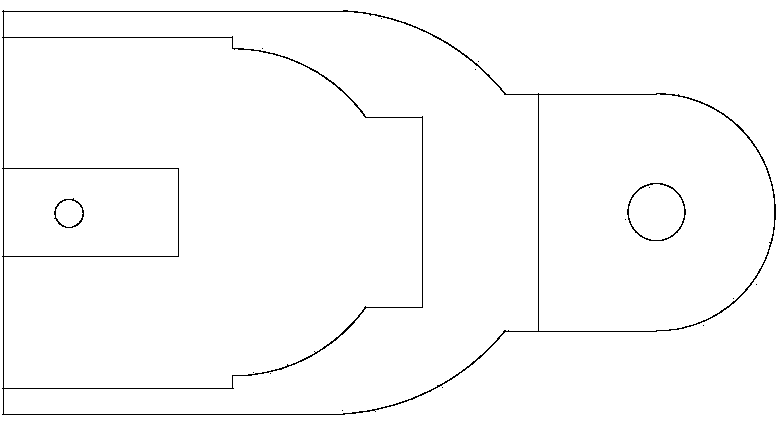

[0032] An installation tool for an overhead line fault indicator, comprising an insulating cup body 1, a connecting device connected to an insulating operating rod is arranged at the lower part of the insulating cup body, and the overhead line fault indicator further comprising a support frame 2. The supporting frame includes two brackets 21 symmetrically arranged at the open end of the insulating cup body. The two brackets are respectively hinged on the insulating cup body. The middle and upper parts of the two brackets are provided with a connecting piece 22. On the plane where the planes of the two brackets intersect, the connecting pieces of the two brackets can swing around the hinge points of the two brackets. The upper parts of the two brackets are respectively provided with vertically distributed positioning bumps 23. The two positioning bumps and the connecting piece are located in the two brackets. On both sides of the plane, the distance between the outer surfaces of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com