Columnar body distinguishing method and columnar body distinguishing device

A columnar body and area technology, which is applied in the field of columnar body discrimination and columnar body discrimination device, can solve the problems of insufficient discrimination and difficulty in discrimination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

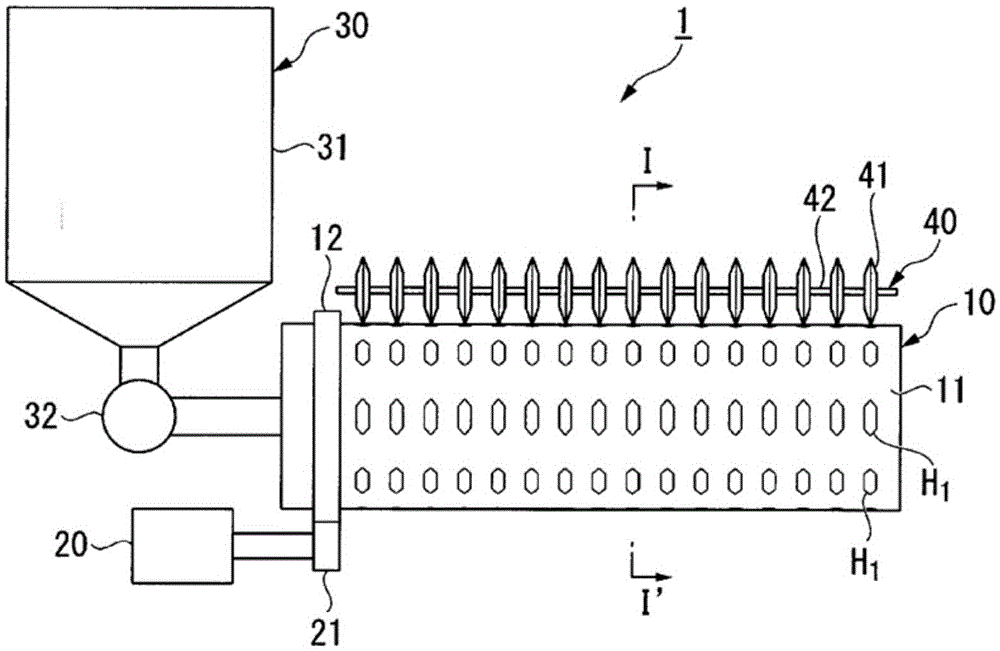

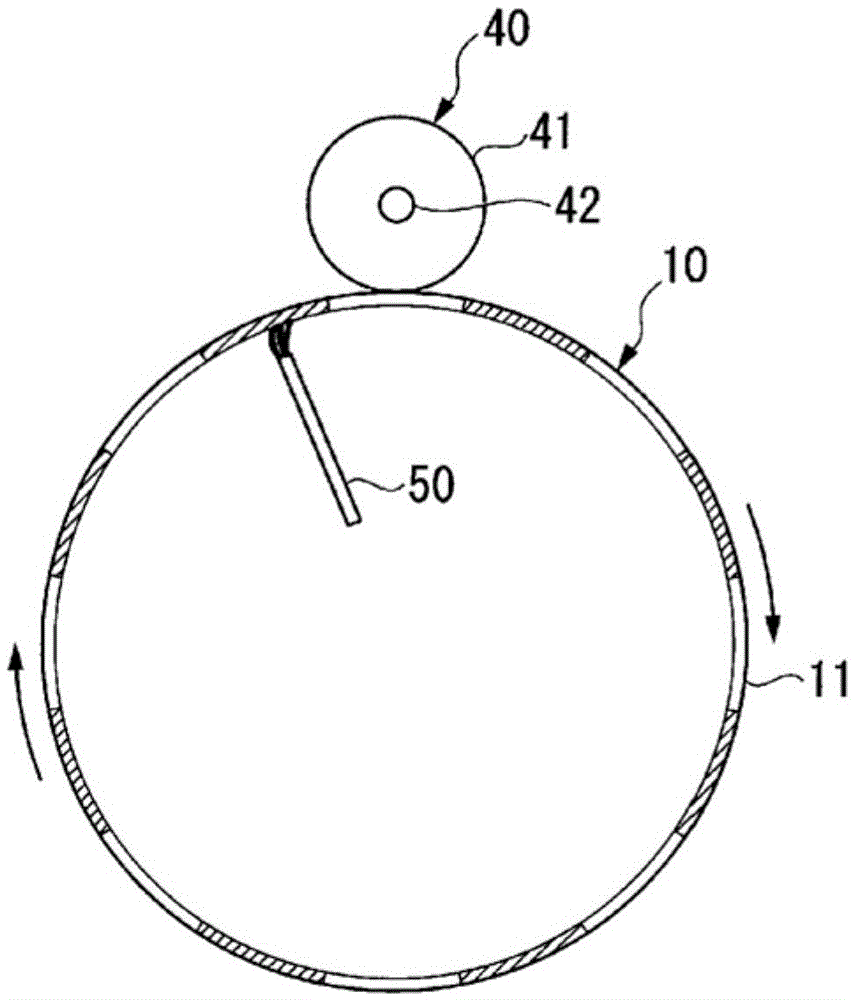

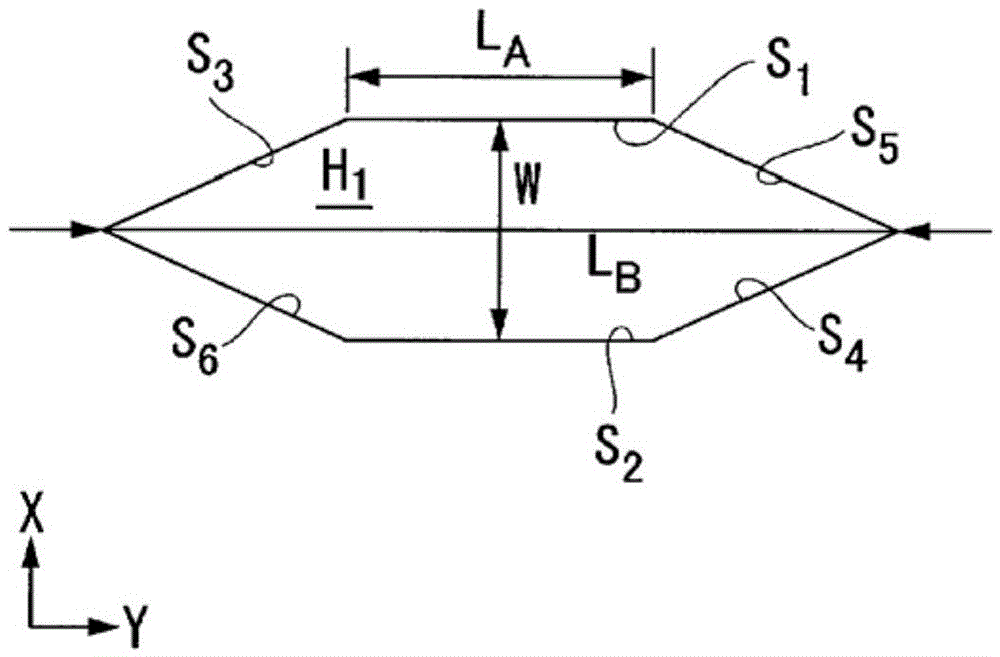

[0137] exist figure 1 and figure 2 In the columnar body distinguishing device 1 shown, use image 3 The opening hole H 1 The W is 5.5mm, L A 4.5mm, L B The 13.5 mm hexagonal cylindrical sieve 10 is divided into a catalyst cylinder (diameter 5 mm, length 5 mm) and a cylinder made of stainless steel spring (diameter (outer diameter) 6 mm, length 6 mm).

[0138] In addition, the opening hole H of the above-mentioned size of the cylindrical sieve 10 used 1 (a) to (d) are satisfied. which is:

[0139] (a) Open hole H 1 A pair of opposite sides (side S 1 with side S 2 , side S 3 with side S 4 , side S 5 with side S 6 ) are parallel and of the same length.

[0140] (b) Open hole H 1 edge S 1 with side S 2 The distance W is larger than the diameter and length of the catalyst cylinder and smaller than the diameter of the spring.

[0141] (c) side S 1 the length L A and the maximum length L of the hexagon in the Y direction B It is the following length, that is: wh...

Embodiment 2

[0155] A catalyst cylinder (diameter 5 mm, length 5 mm) and a stainless steel spring (diameter (outer diameter) 6 mm, length 6mm) were distinguished. During the differentiation process, a vibrator is used to vibrate the sieve section. In addition, similarly to Example 1, the discrimination was evaluated. The results are shown in Table 1.

[0156] In addition, since the flat sieve part was used in this example, the discrimination index E was calculated|required by substituting "remaining in the cylindrical sieve" with "remaining on the sieve part".

Embodiment 3

[0158] Align the opening holes of the cylinder sieve according to the Figure 17 The approximate slot shape shown is the opening hole H made into a slot 6 (L A : 5mm, L B : 28mm), such as Figure 19 As shown, except that the arrangement in the X direction is zigzag and the arrangement in the Y direction is in series, it is the same as in Example 1, and two types of cylinders are distinguished from each other. In addition, similarly to Example 1, the discrimination was evaluated. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com