Pot seedling pipe penetrating self putting type transplanting machine

A technology for transplanting machines and potted seedlings, which is applied in the field of dry land transplanting machinery, can solve the problems of slow development of automatic transplanting machinery, unfavorable promotion, time-consuming and labor-intensive problems, etc., and achieve the effects of easy promotion, reduced labor intensity, and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

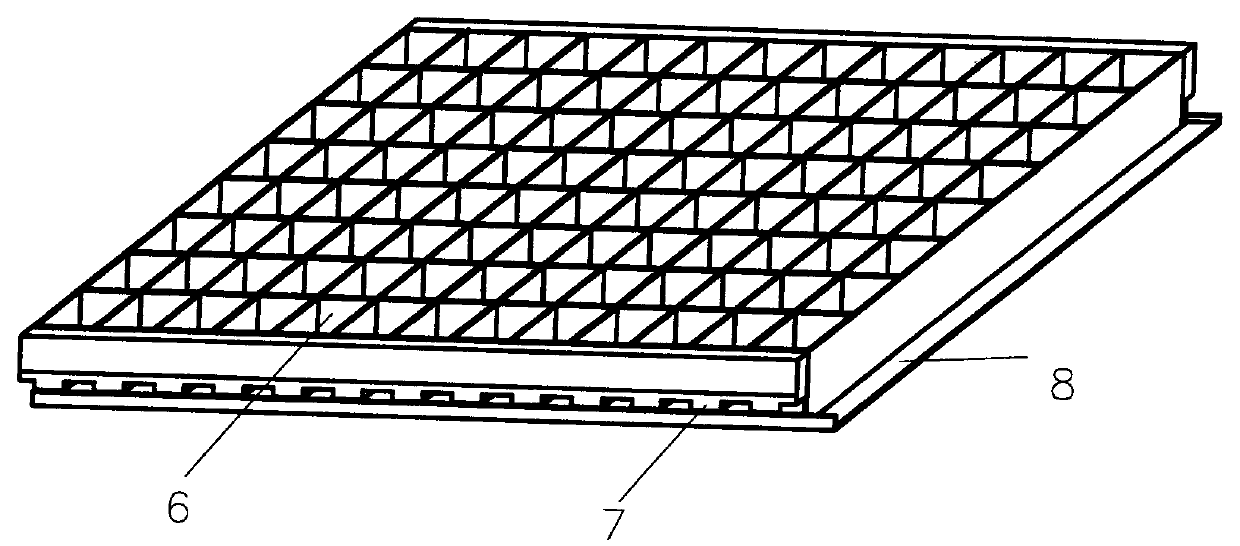

[0017] In order to ensure that the pot seedlings can successfully realize self-injection, it is the key to keep the pot seedlings intact. Most of the existing pot seedlings are big on the top and small on the bottom, and the top is heavy and the bottom is light, so it is impossible to realize self-throwing. Therefore, it is necessary to change the pot shape of the pot seedlings first. Whether it is a round pot seedling or a square pot seedling (corn seedlings in a directional pot should be square), the new seedling pot (patent No. 2013207553904) pull up half or the whole pot of pot seedlings, and directly move them into the seedling pot of the pot seedlings through-pipe self-dropping transplanter of the present invention.

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described

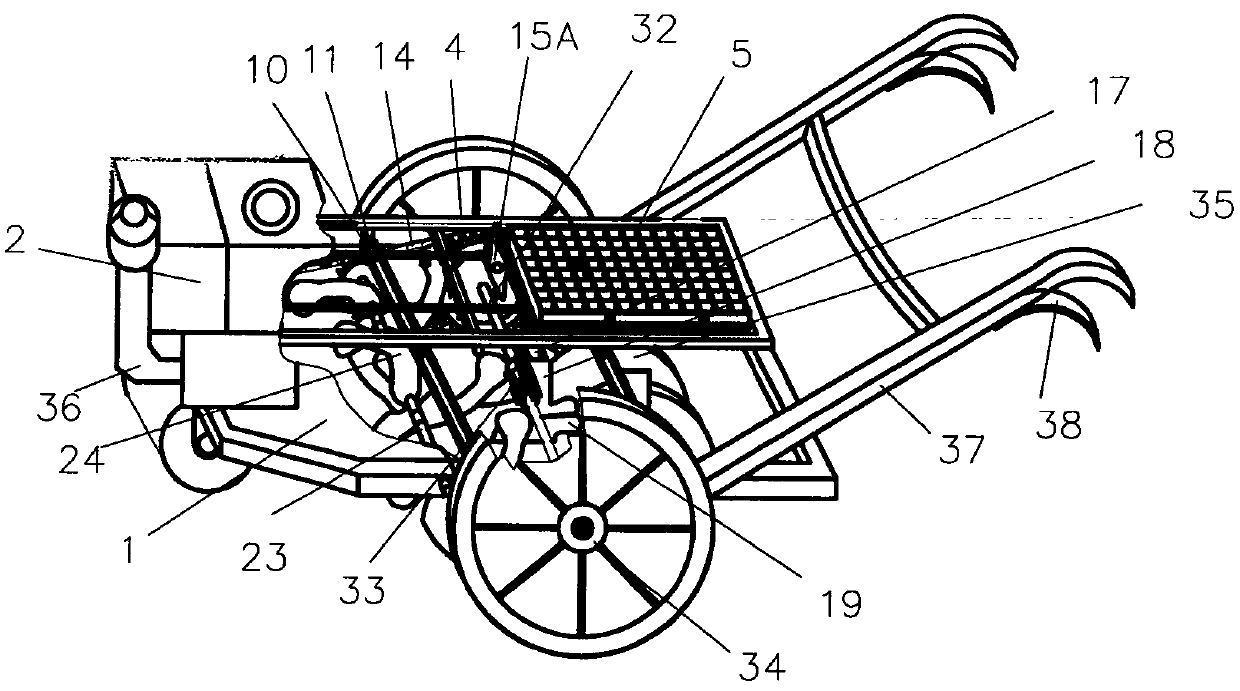

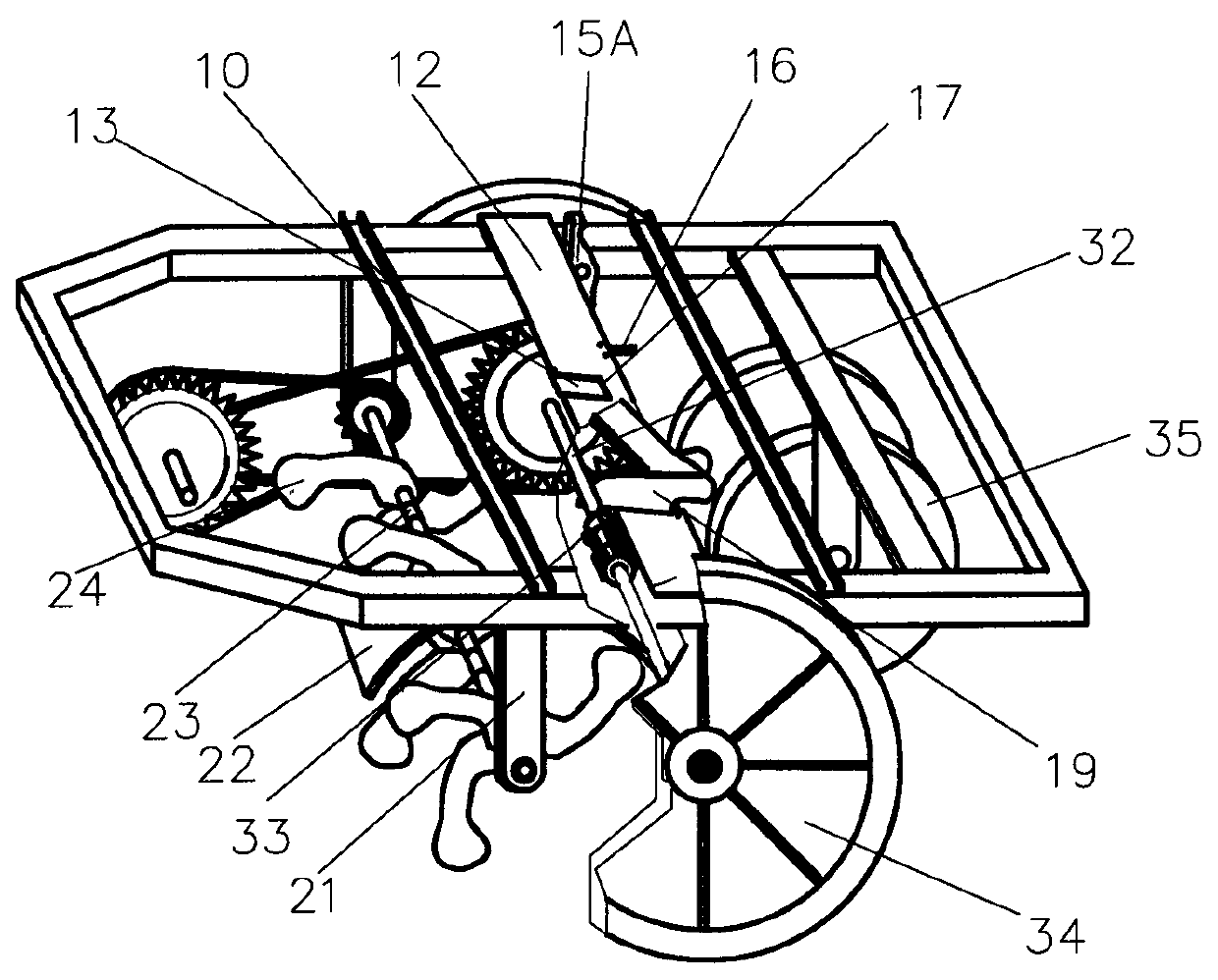

[0019] Such as figure 1 As shown, there is a disc frame 4 on the frame 1, and the disc frame 4 carries the seedling tray 5. The front e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com