Vertical type lathe and milling machine worktable with brake function

A technology of braking function and worktable, applied in manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of inaccurate positioning and worktable deflection, and achieve the effect of good shock absorption capacity and large deformation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

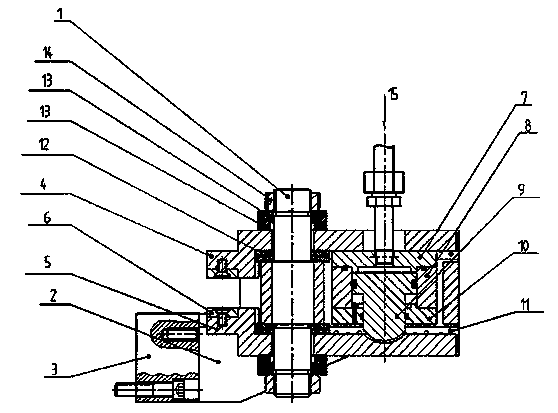

[0027] On the basis of the above structure, the present invention adds a limiting device 23 , a locking module 24 , a driving device 25 , and a fixed support 2 .

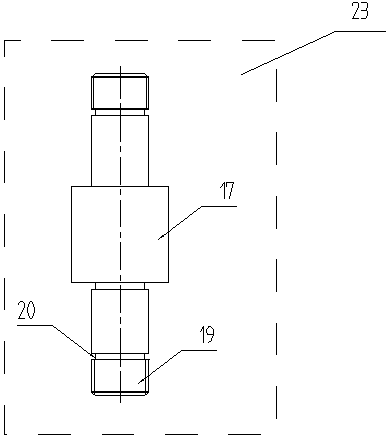

[0028] The concrete structure of limiter 23 is as figure 2 As shown: the limiting device 23 is a locking rod 1, the locking rod 1 is an optical axis, and the outer circular surface in the middle of the optical axis is provided with a flange 17 through integral molding, and the length of the flange 17 is the entire optical axis 1 / 3 of the length, the two ends of the optical axis 18 are respectively provided with threads 19, the length of the threads 19 is 1 / 6 of the length of the entire optical axis, and the rear ends of the two threads 19 are respectively provided with thread grooves 20, and the locking rod 1 of this device Both ends are provided with threads 19 to be connected with lock nuts 14, so that the degree of tightness of the device can be adjusted.

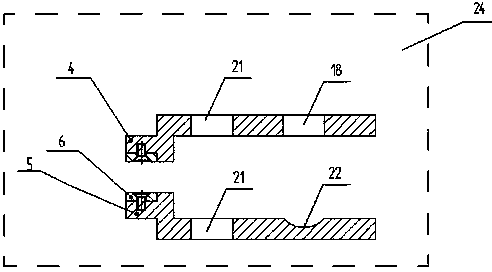

[0029] The concrete structure of locking module 24...

Embodiment 2

[0033] On the basis of Embodiment 1, the present invention also increases a heightening block 3 .

[0034] The concrete structure of heightening block 3 is as figure 1 Shown: heightening block 3 is a rectangular plate, and heightening block 3 is directly connected with workbench 16 by bolts, setting heightening block 3 can easily adjust the height that this device is installed on the workbench.

[0035] The specific connection relationship between the heightening block 3 and the device is as follows: the fixed support 2 and the heightening block 3 are integrally formed, and the braking device is connected with the fixed support 2 by a fixed manner.

[0036] The specific connection relationship between the brake device and the workbench is as follows: this device uses two brake devices to be installed on the radial flange of the workbench 16 in a diagonally symmetrical manner, specifically the upper locking block 4 and the lower locking block 5 left The notch space formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com