Drilling chuck correcting method

A correction method and drill chuck technology are applied in the field of drill chuck correction, which can solve problems such as hidden dangers in production, yaw, and excessive use of drill chucks, and achieve the effect of solving yaw

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

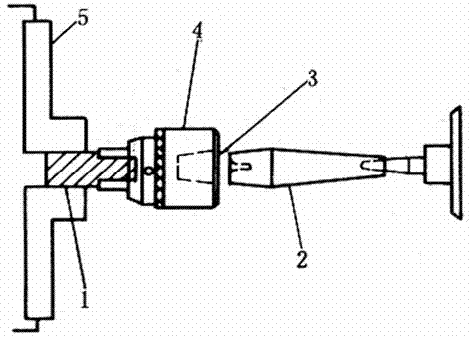

[0012] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] like figure 1 Shown, a drill chuck calibration method, the method steps are as follows:

[0014] a. Install the chuck taper shank 2 between the two centers on the lathe, place the small tool holder to the correct angle, and turn the taper shank to the correct angle;

[0015] b. Then install and clamp a bar 1 on the chuck 5, drive out the part that can be clamped by the drill chuck, and clamp the chuck 4 to the rod 1;

[0016] c. The small tool holder is still renovating the taper hole 3 of the chuck 4 at the angle of turning the taper handle 2, and the chuck has been corrected at this time;

[0017] d. Insert the taper shank into the taper hole of the chuck, and the other end is positioned by the top of the tailstock. There is no swing phenomenon during the turning of the car, which shows that the calibration of the chuck is corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com