Integrated design method of hypersonic waverider fuselage and inlet

A hypersonic, air inlet technology, which is used in the combustion of the air inlet of the power plant, the air inlet of the turbine/propulsion device, and aircraft parts, etc., can solve the problem that the high lift-to-drag ratio characteristics of the waverider cannot be fully utilized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

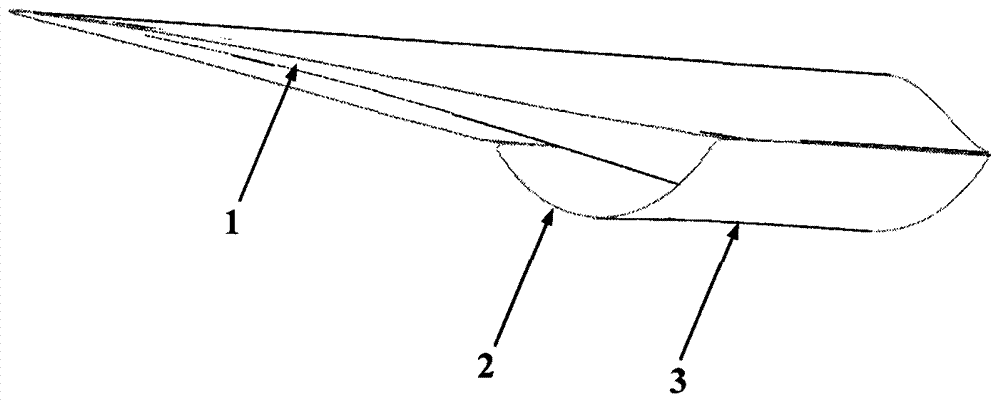

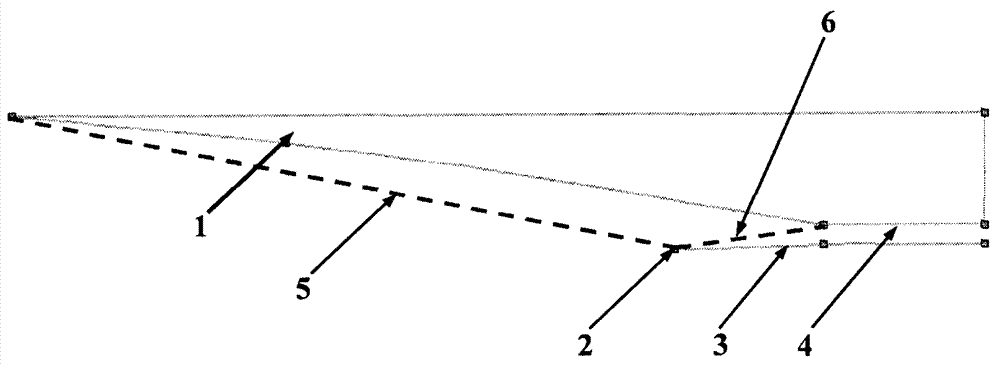

[0031] The present invention provides a method for the integrated design of a hypersonic waverider fuselage and an air inlet. The waverider is used as the entire hypersonic aircraft fuselage, which is referred to as the waverider fuselage. At the same time, it is tracked with the streamline and turned outward to the air inlet. Integration, including the following steps:

[0032] Step S1, designing the pointed rotor, and solving the supersonic axisymmetric flow field around the zero angle of attack pointed rotor.

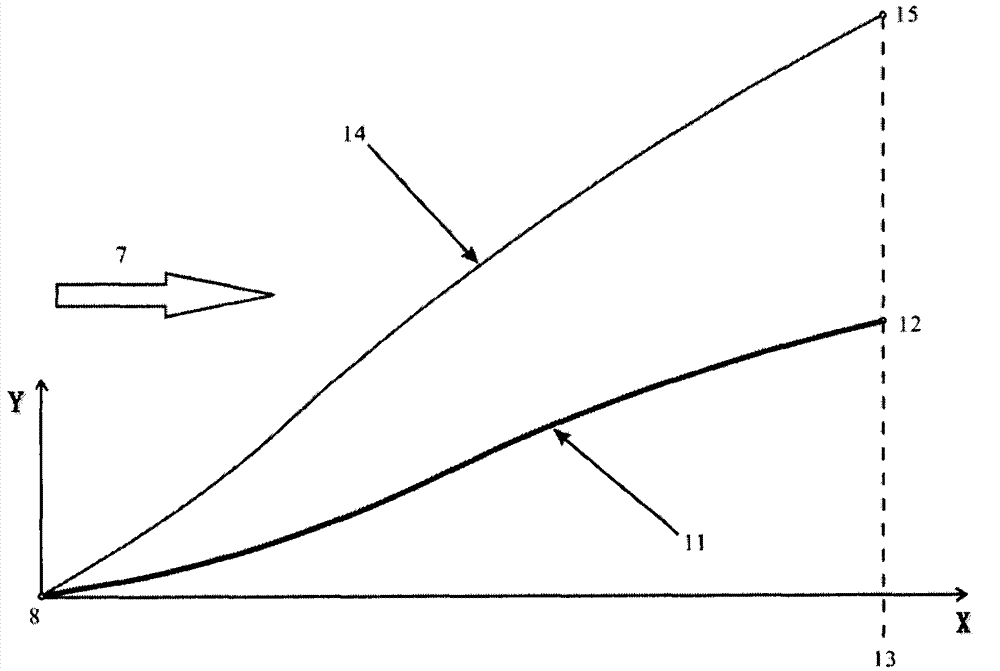

[0033] Such as image 3 As shown, let the curve 11 be the generatrix of the pointed rotor, the starting point of the bus is point 8, and the end point of the bus is point 12. Under the action of zero angle of attack and supersonic incoming flow 7, the pointed rotor can produce forward Edge shock wave 14, the end point of leading edge shock wave 14 on the bottom cross-section 13 of the pointed rotor is point 15.

[0034] The condition of the supersonic incoming flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com