Method and system for autonomous monitoring on dining place food safety

A food safety and autonomous technology, applied in the field of computer applications, can solve the problems of long inspection cycle, high cost, and the inability of manpower to supervise enterprises effectively, so as to avoid food safety problems and avoid recurrence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

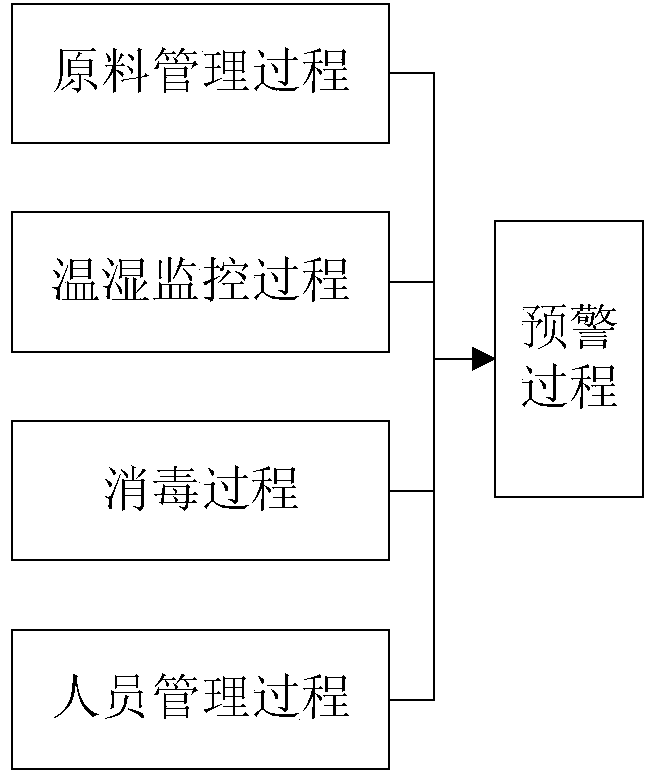

[0061] see figure 1 As shown, the method of the present invention analyzes and warns the data generated in the raw material management process, temperature and humidity monitoring process, disinfection management process and personnel management process through the early warning process, and realizes the independent monitoring of food safety of each catering place within the jurisdiction of the supervisory unit. Supervision.

[0062] The invention provides an autonomous food safety supervision method for a restaurant, which specifically includes: a raw material management process, a temperature and humidity monitoring process, a disinfection management process, a personnel management process, and an early warning process:

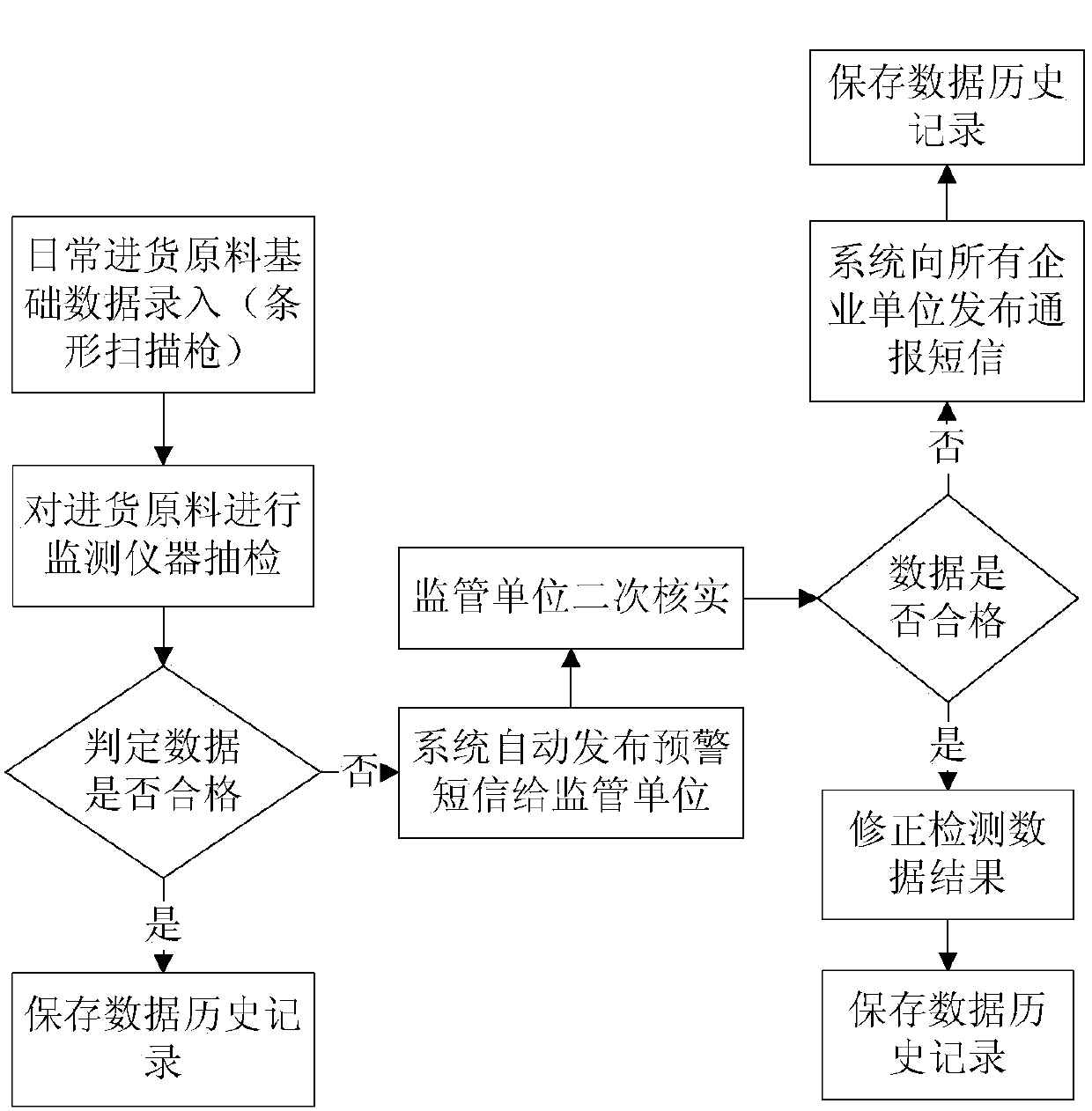

[0063] The raw material management process: analyze whether there are problem raw materials according to the basic data of the incoming raw materials entered, so as to send the problem raw material information to the supervision unit and each catering est...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com