Device for reinforcing a supporting sub-frame

A load-bearing, sub-frame technology, used in suspension, vehicle components, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

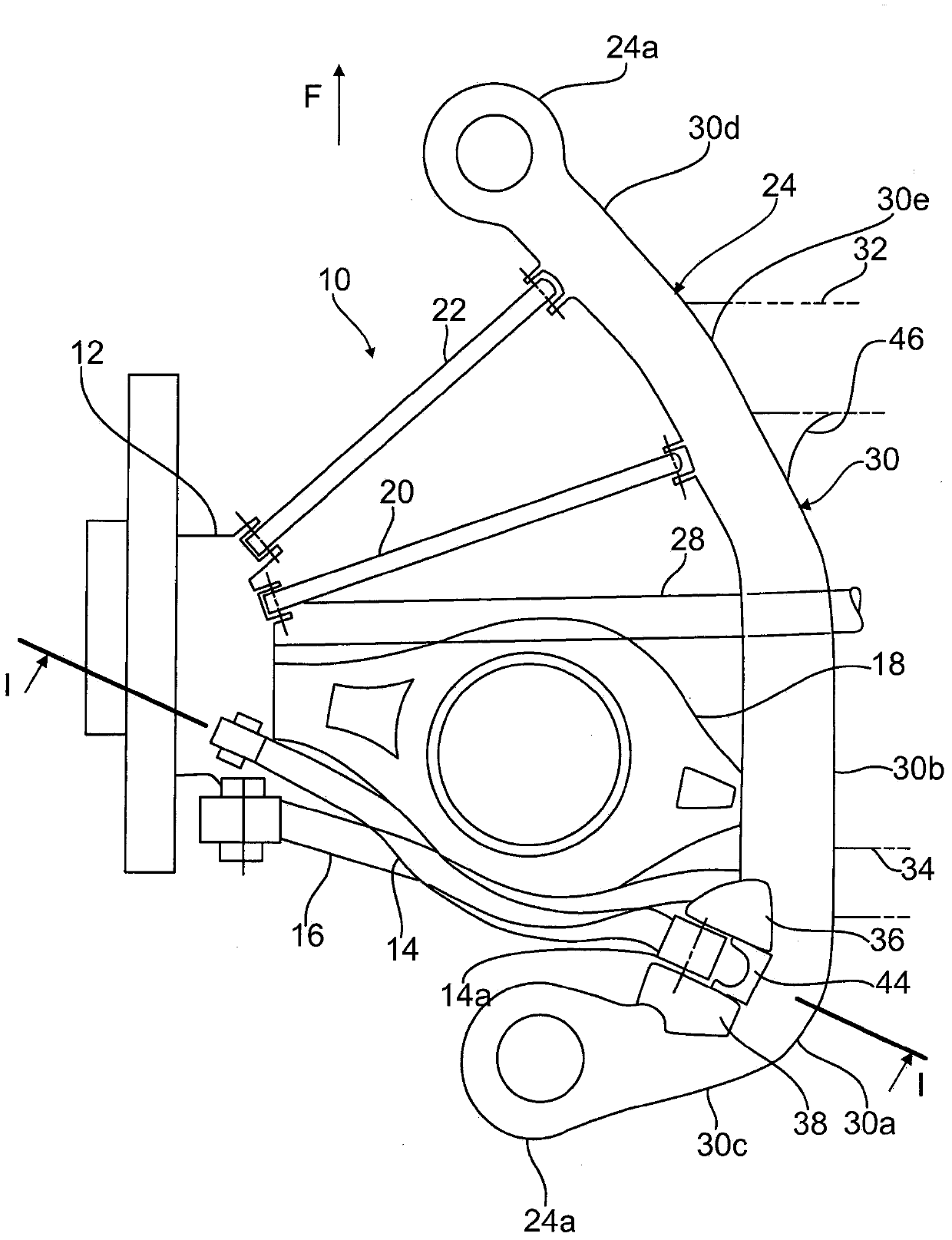

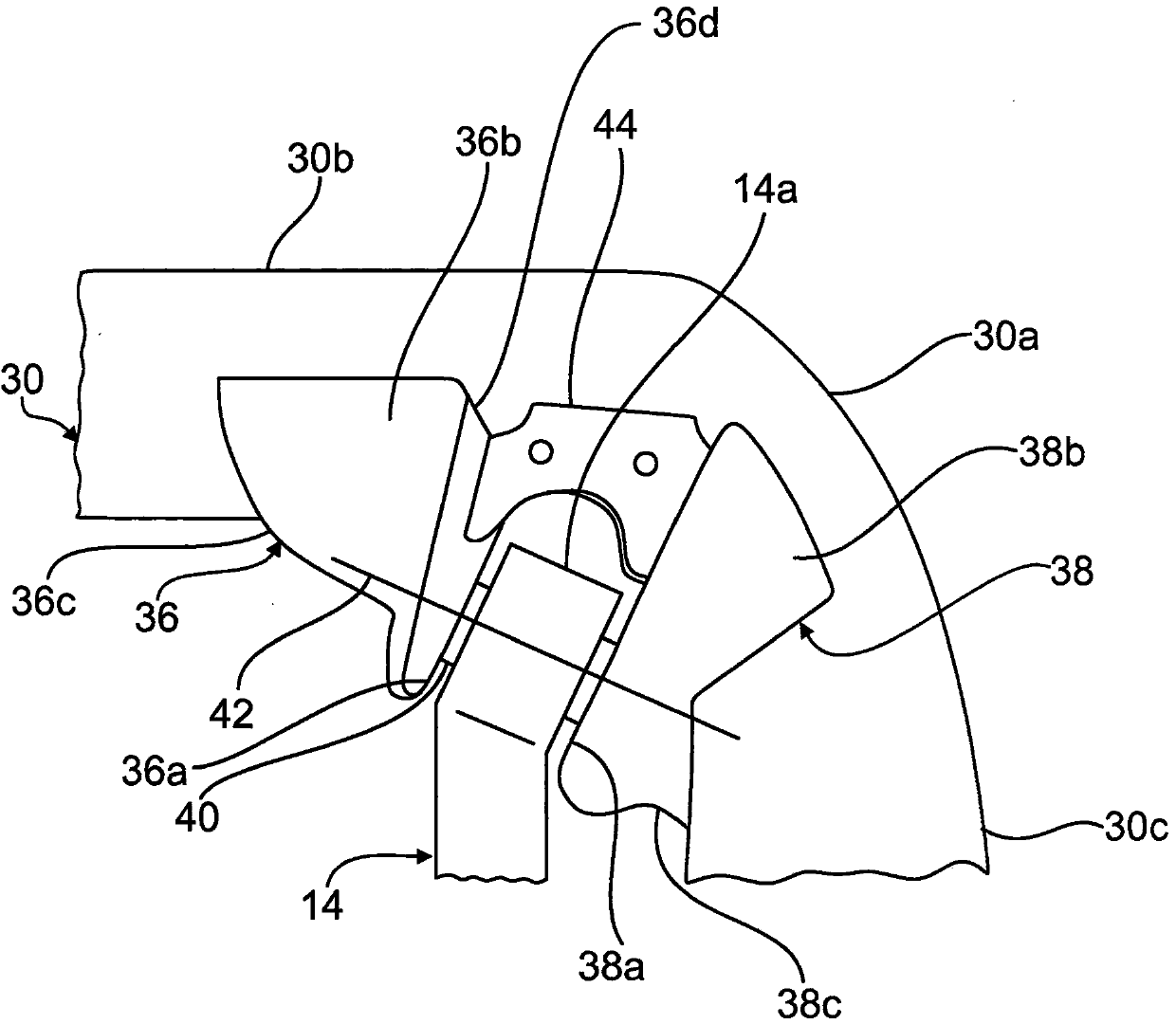

[0015] figure 1 In a plan view, the left-hand rear wheel suspension 10 of the motor vehicle is shown, but the rear wheel suspension is described only in a way necessary for the understanding of the invention.

[0016] The hub bracket 12 of the wheel suspension 10 is held on a five-link suspension, wherein the hub bracket 12 is guided by five spatially distributed control arms 14, 16, 18, 20, 22, the control arms On the other side, it is hinged to a subframe 24 which is only partially shown. In addition, the universal joint shaft 28 of the power transmission / powertrain (not shown) that drives the rear wheels can be seen.

[0017] The sub-frame 24 includes two longitudinal beams 30 (only the left longitudinal beam 30 is shown, and the right longitudinal beam is basically symmetrical) and two transverse beams 32, 34 and are supported in a four-point support structure. The component receiving portion 24a is connected to the vehicle body (not shown) of the motor vehicle, for example, t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap