Cake baking jig

A baking and jig technology, applied in the direction of baking cans, etc., can solve the problems of difficult control of pressure and uneven heating of the chassis, and achieve the effect of good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to understand the technical characteristics and practical effects of the present invention in detail, and to realize them according to the contents of the specification, the detailed description is as follows with the preferred embodiment shown in the accompanying drawings:

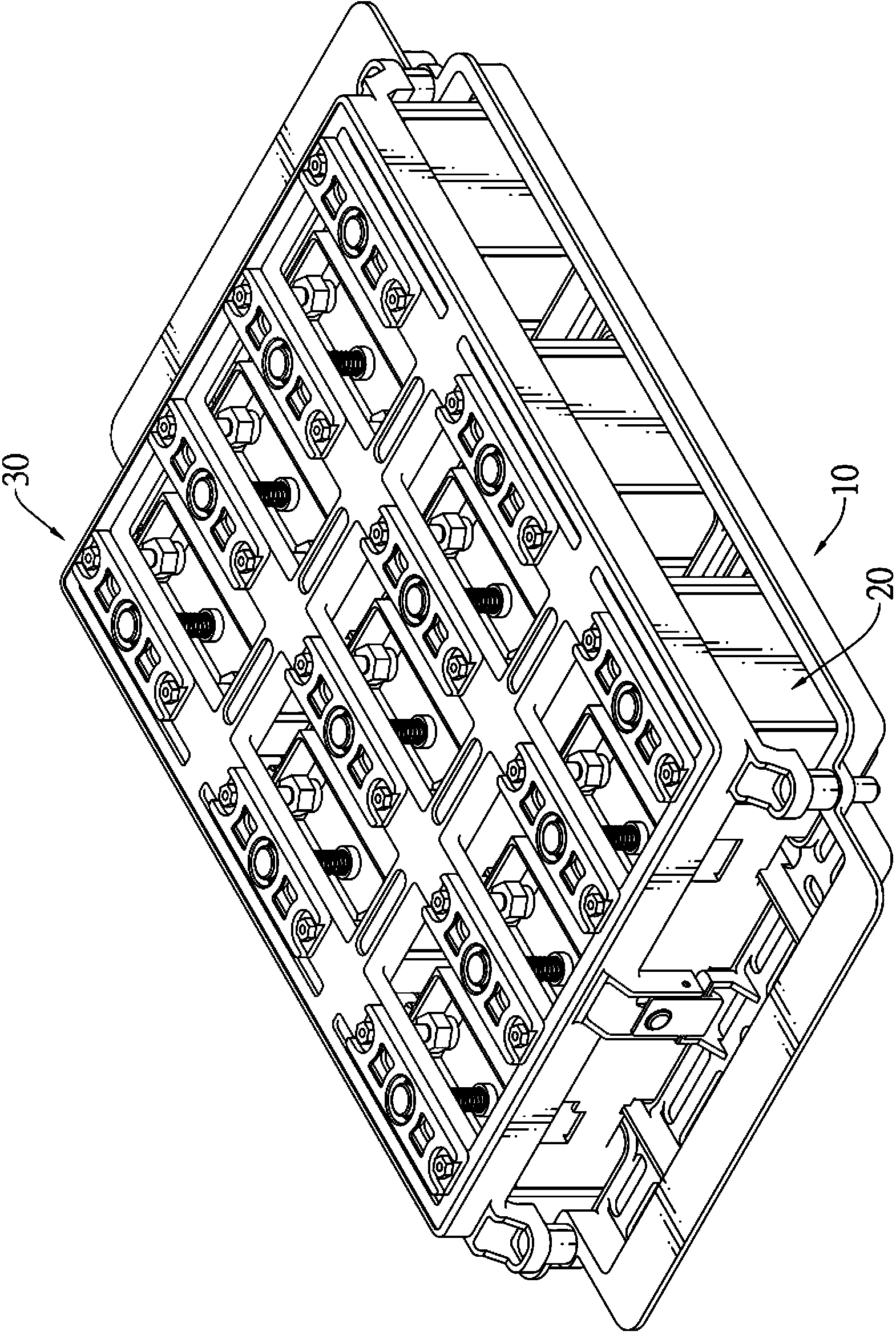

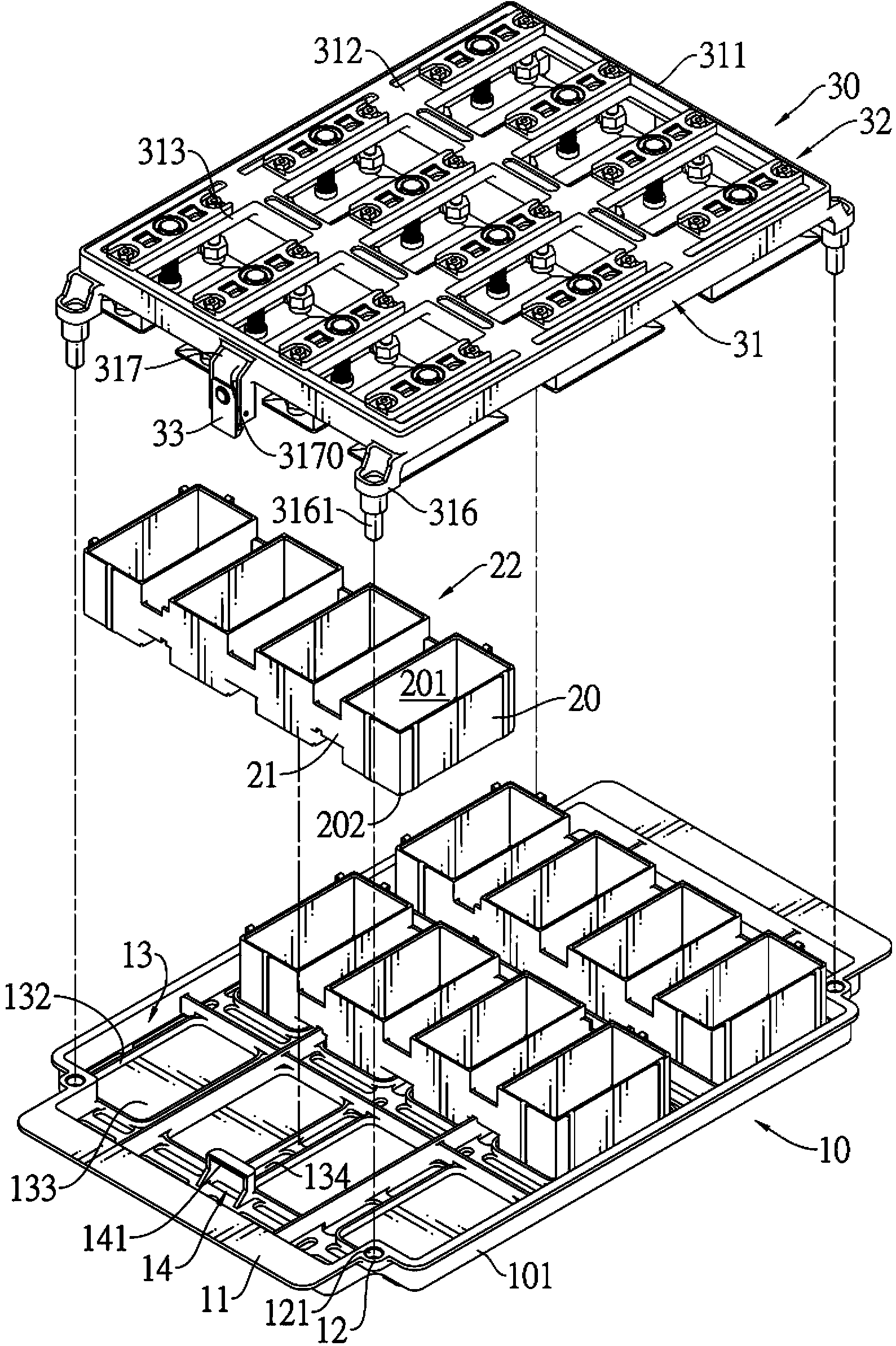

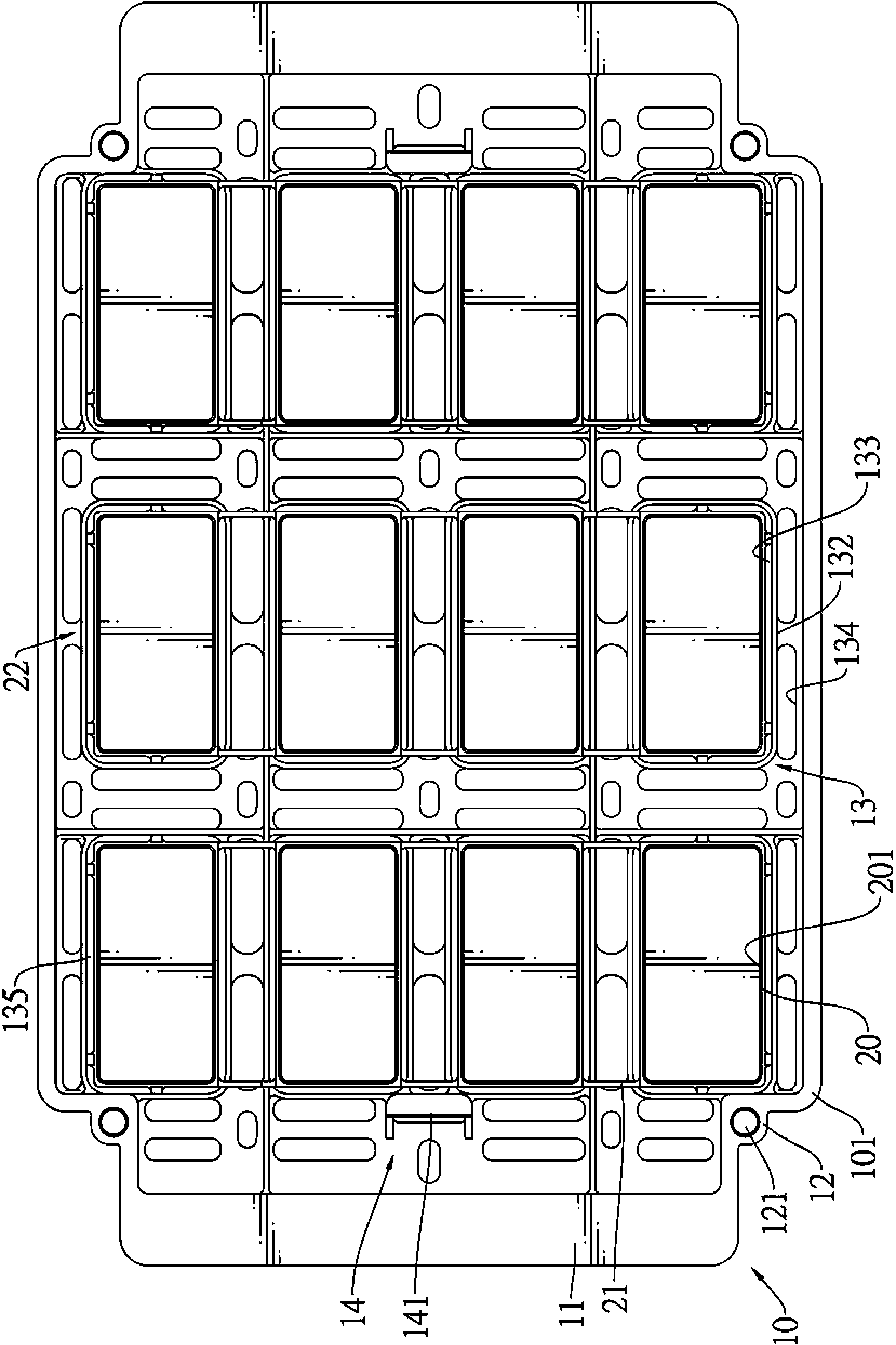

[0052] The present invention is a kind of pastry baking jig, please refer to Figure 1 to Figure 6 The first preferred embodiment of the present invention comprises a baking tray 10 , a plurality of shape molds 20 and a baking cover tray 30 .

[0053] Such as figure 1 and figure 2 As shown, the baking chassis 10 has a rectangular tray body 101, and the two short sides of the tray body 101 respectively protrude laterally to form a gripping plate 11 for holding by both hands, between the tray body 101 and the two sides A positioning seat 12 is formed at each intersecting corner of the holding plate 11, and a positioning hole 121 for positioning the baking cover plate is provided at the p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap