A Segmentally Welded Variable Section Box Frame Longitudinal Beam

A technology of segmented welding and variable cross-section, applied in the field of auto parts, can solve the problems of difficult to guarantee dimensional accuracy, difficult to control the amount of stamping springback, and high mold investment, so as to reduce mold investment and welding process, and improve rigidity and strength. , the effect of lowering the center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

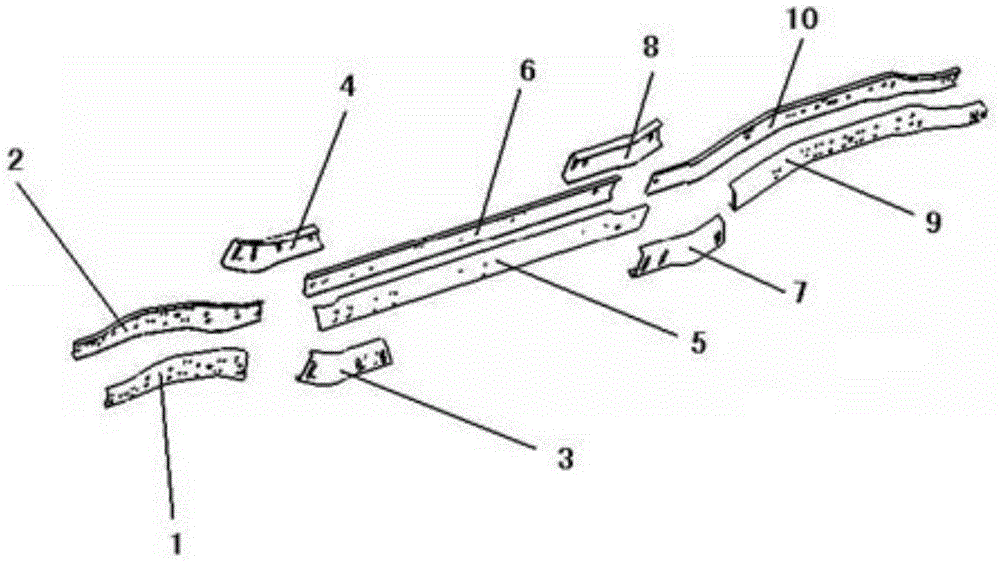

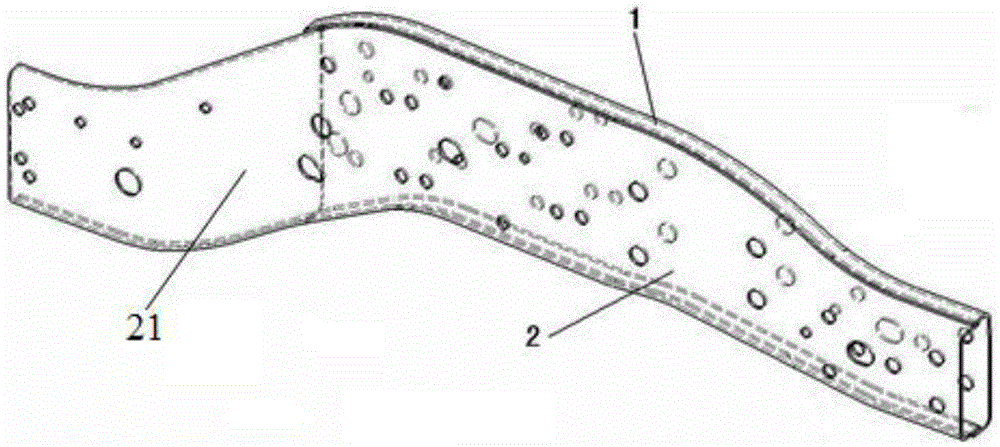

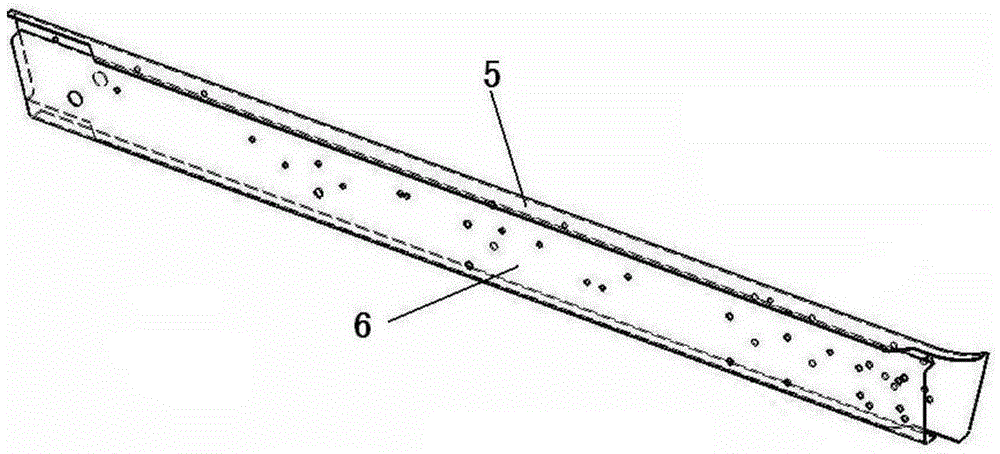

[0032] Such as figure 1 As shown, the present invention includes a front longitudinal beam assembly, a middle longitudinal beam assembly, a rear longitudinal beam assembly, a front reinforced sealing plate and a rear reinforced sealing plate. Such as figure 2 As shown, the front longitudinal beam assembly is formed by lap welding of the wings of the channel-shaped front longitudinal beam outer panel 1 and the wing of the channel-shaped front longitudinal beam inner panel 2, and the wings of the front longitudinal beam inner panel 2 are formed on the Between the two wings of the outer sheet 1; such as image 3 As shown, the center stringer assembly is formed by lap welding of the wings of the channel-shaped center stringer outer sheet 5 and the channel-shaped center stringer inner sheet 6 wings, and the wings of the center stringer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com