Paint extractor

An extractor and paint technology, used in emptying containers, bottle filling, packaging, etc., can solve the problem of inconvenient access to paint, and achieve the effects of eliminating cleaning, convenient operation, and easy control of taking amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

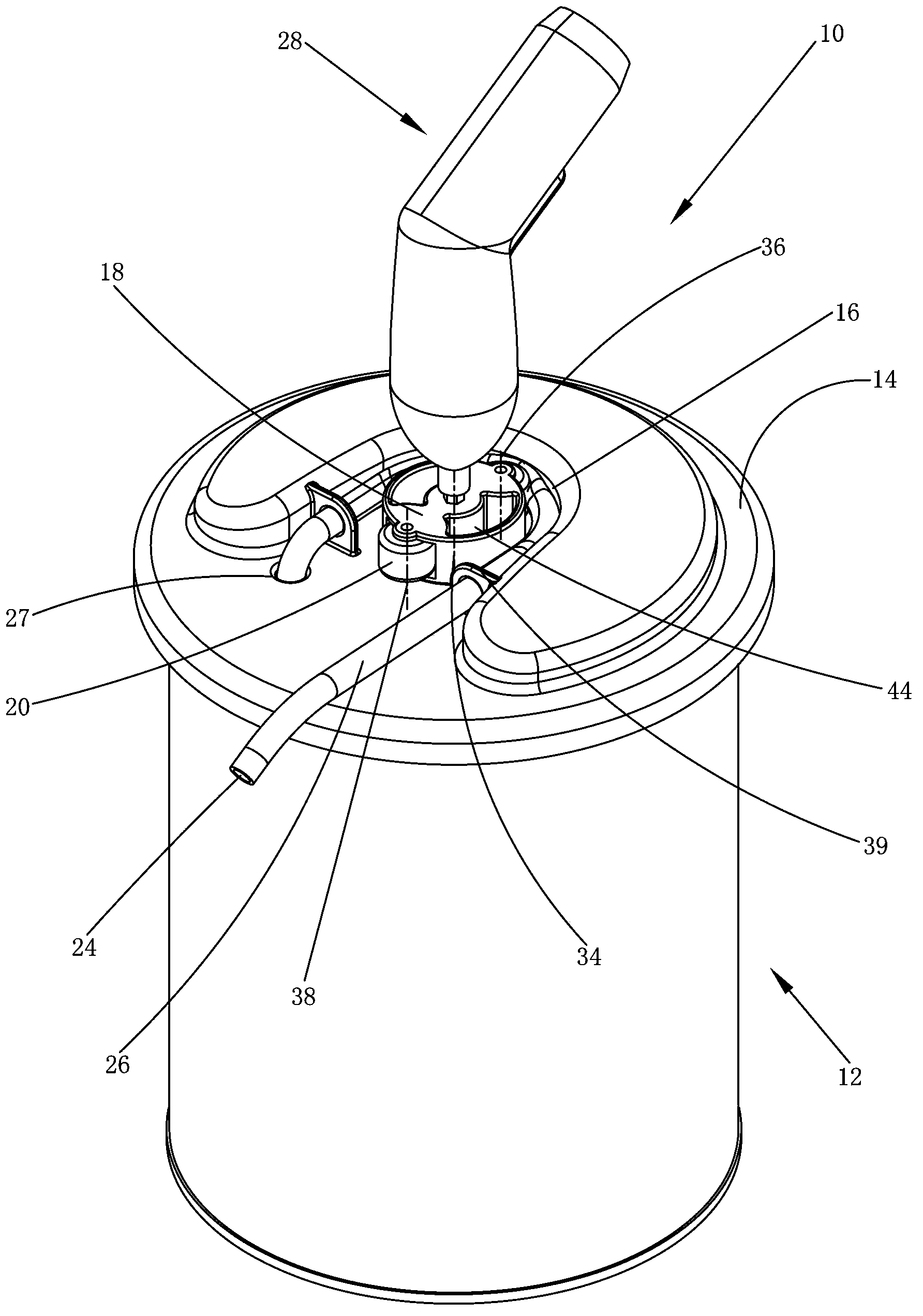

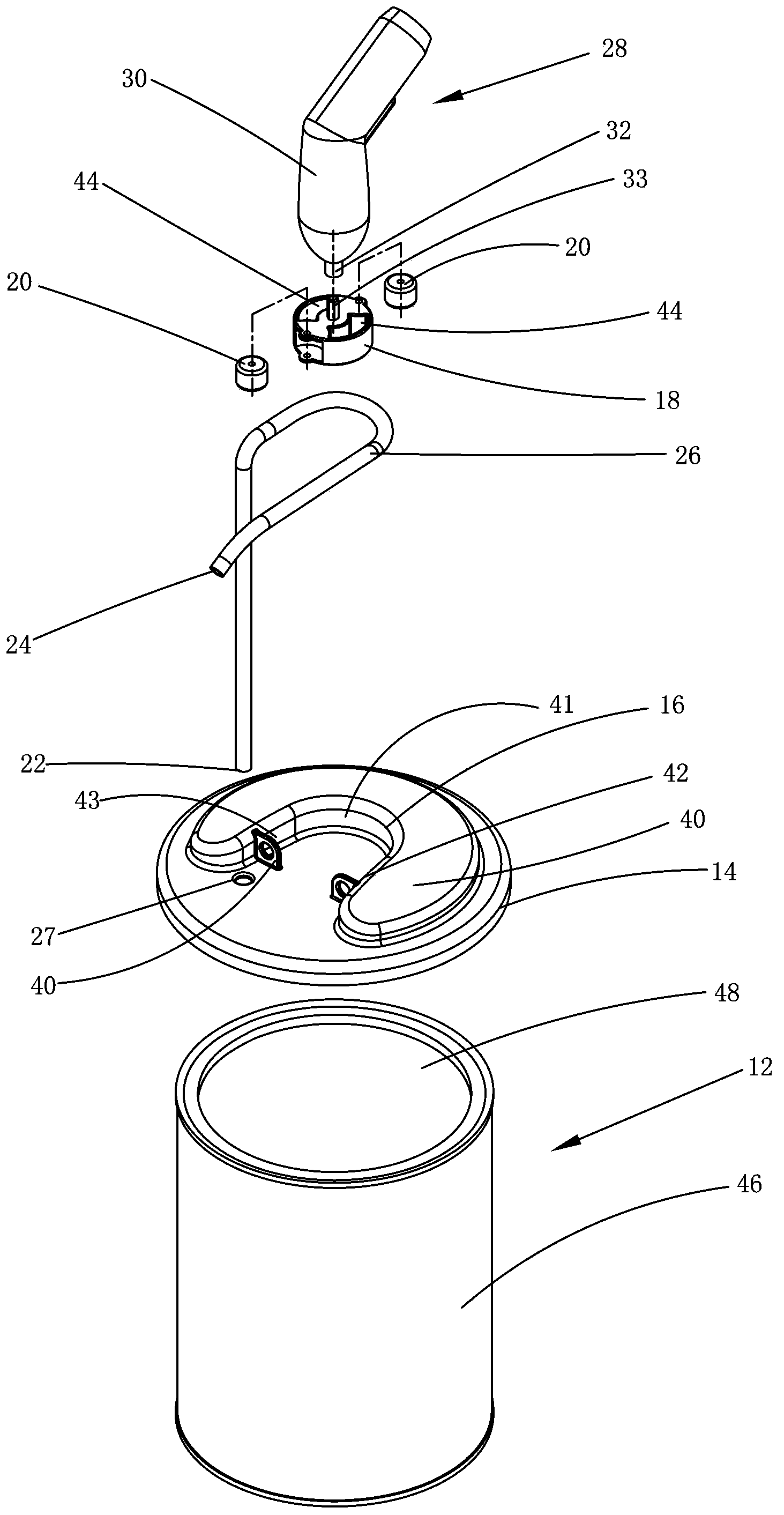

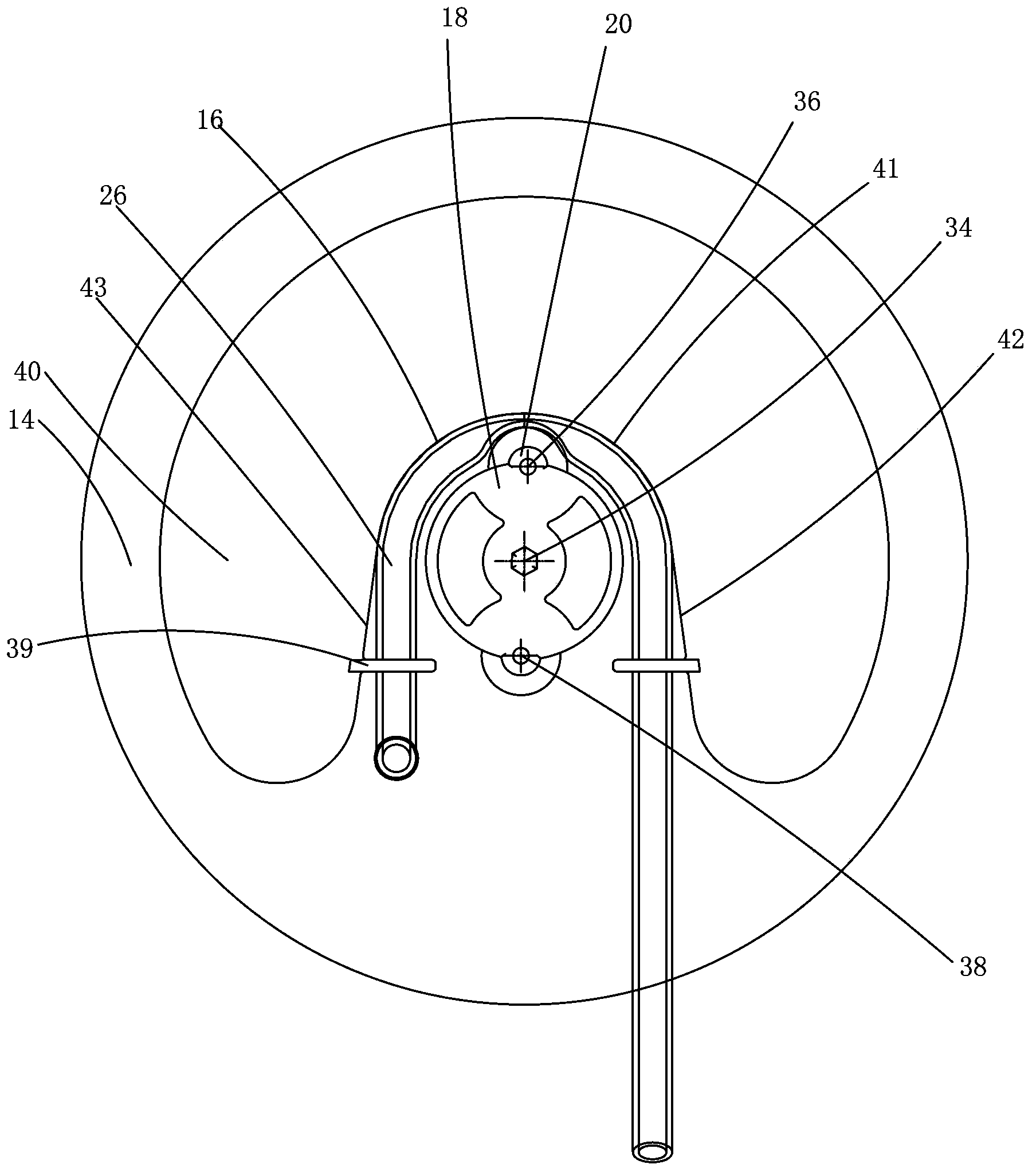

[0028] Such as figure 1 As shown, a paint extractor 10 is used to extract paint in a container 12 . The paint extractor 10 includes a support base 14 on which an arc guide portion 16 is arranged; a mounting base 18 rotatably disposed on the support base 14 ; and a roller 20 rotatably disposed on the mounting base 18 .

[0029] further reference figure 2 with image 3 , the paint extractor 10 also includes a hose 26 with an inlet 22 and an outlet 24, the hose 26 is located between the arc guide 16 and the roller 20, and the roller 20 squeezes the hose 26, the inlet 22 of the hose 26 is located in the container 12, its outlet 24 is located outside the container 12. Wherein, the paint extractor 10 also includes a power tool 28 that is optionally matched with the mounting base 18, and the power tool 28 cooperates with the mounting base 18 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com