Composite component manipulator scanning pose quaternion converting method

A conversion method, quaternion technology, applied in electrical digital data processing, special data processing applications, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the problem that the tool position data cannot be used by the manipulator, and achieve rotation transformation calculation concise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention is described in detail below:

[0020] The relative motion between the measured component and the probe can be regarded as the general motion of two rigid bodies, which can be realized by rotation around a certain axis and translation along this axis. The rotation q of the space is represented by the quaternion; when the translation part is considered, the translation vector can be set as p, so that the entire transformation process of the measured component is formed by the quaternion rotation q and the translation vector p. The expression is:

[0021] p B =qp A q -1 +p (1)

[0022] Among them, p A is the value before coordinate transformation, p B is the converted coordinate value.

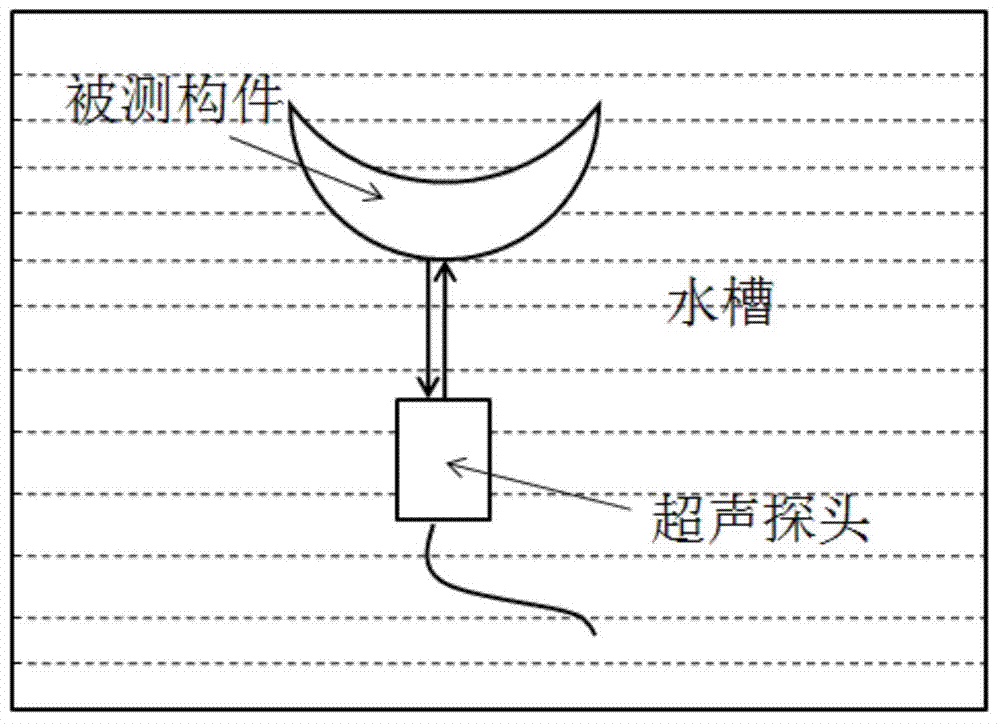

[0023] The component under test and the ultrasonic probe are in the world coordinate system O 0 x 0 Y 0 Z 0 In order to introduce the method simply, we simplify the measured component into a rigid body, such as figure 1 . Let t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com