Solar panel installation assembly comprising vacuum chuck head with in-plane double flexible seal strips

A vacuum suction cup and flexible sealing technology, which is applied to electrical components, transportation and packaging, circuits, etc., can solve problems such as heavy workload and large solar panel volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

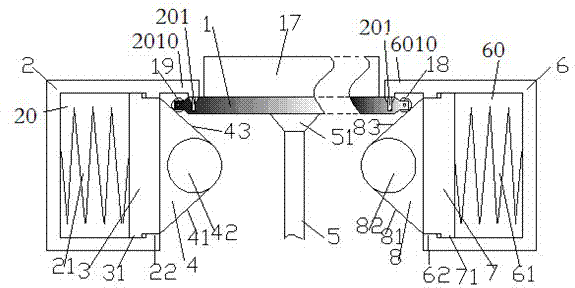

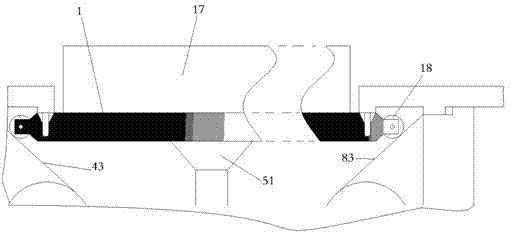

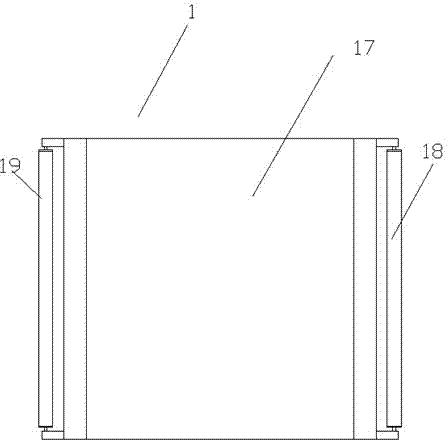

[0021] combined with Figure 1-7 , to explain the present invention in detail. Note that the drawings are not to scale.

[0022] A solar panel installation assembly comprising a vacuum chuck head 51 with in-plane double flexible sealing strips, comprising a frame assembly 200, a plurality of installation boards 1 and a loading and unloading drive device 5, each of the plurality of installation boards 1 uses For installing the solar panel 17, the frame assembly 200 has a plurality of installation windows, each of which is used to carry the one installation panel 1 so that the solar panel can be in a working state of receiving sunlight;

[0023] Each of the installation windows includes a left frame 2, a right frame 6, and a window area 26 between the left frame 2 and the right frame 6, and the window area 26 is used to expose the solar panel to receive sunlight;

[0024] There is a left cavity 20 in the left frame 2, and a left slider 3 is slidably arranged in the left cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com