Device for comprehensively preventing guide line from oscillating

An all-round, conductive technology, applied in the direction of mechanical vibration attenuation devices, etc., can solve the problems of shortened service life of the anti-vibration hammer, increased external force of the anti-vibration hammer, and reduced service life of the wire, so as to prevent vibration and galloping, enhance the anti-vibration effect, Effect of preventing conductor vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with embodiment. The following examples are only specific embodiments of the present invention, but the design concept of the present invention is not limited thereto, and any insubstantial changes made to the present invention by using this concept should be regarded as violations of the protection scope of the present invention.

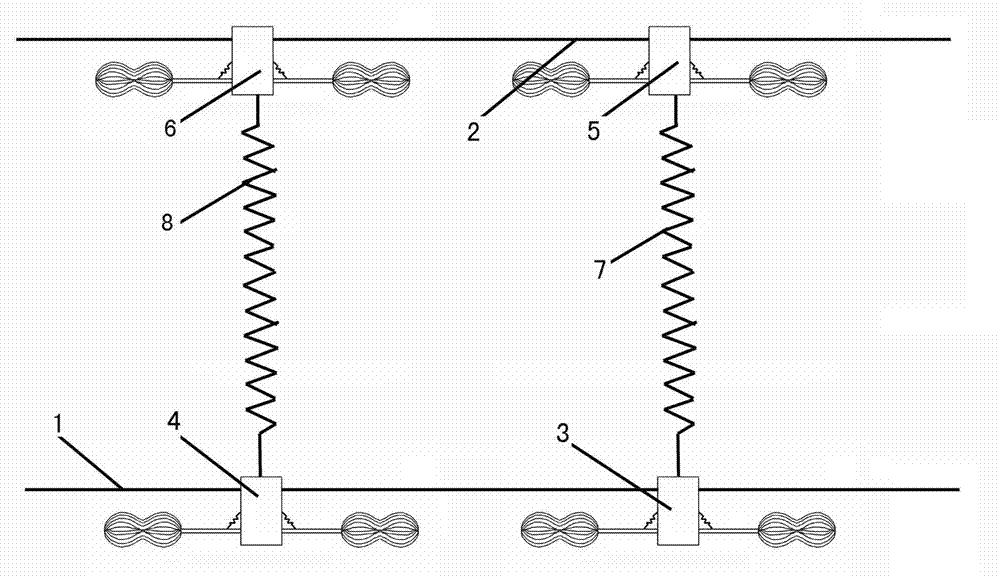

[0019] Such as figure 1 As shown, the device for preventing wire vibration in all directions of the present invention has a specific structure as follows: the first wire 1 and the second wire 2 are arranged in parallel in the horizontal direction, and a first anti-vibration hammer 3 and a second anti-vibration hammer are installed on the first wire 1 . Hammer 4, the third anti-vibration hammer 5 and the fourth anti-vibration hammer 6 are installed on the second wire 2, the first shock-absorbing spring 7 is arranged between the first anti-vibration hammer 3 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com