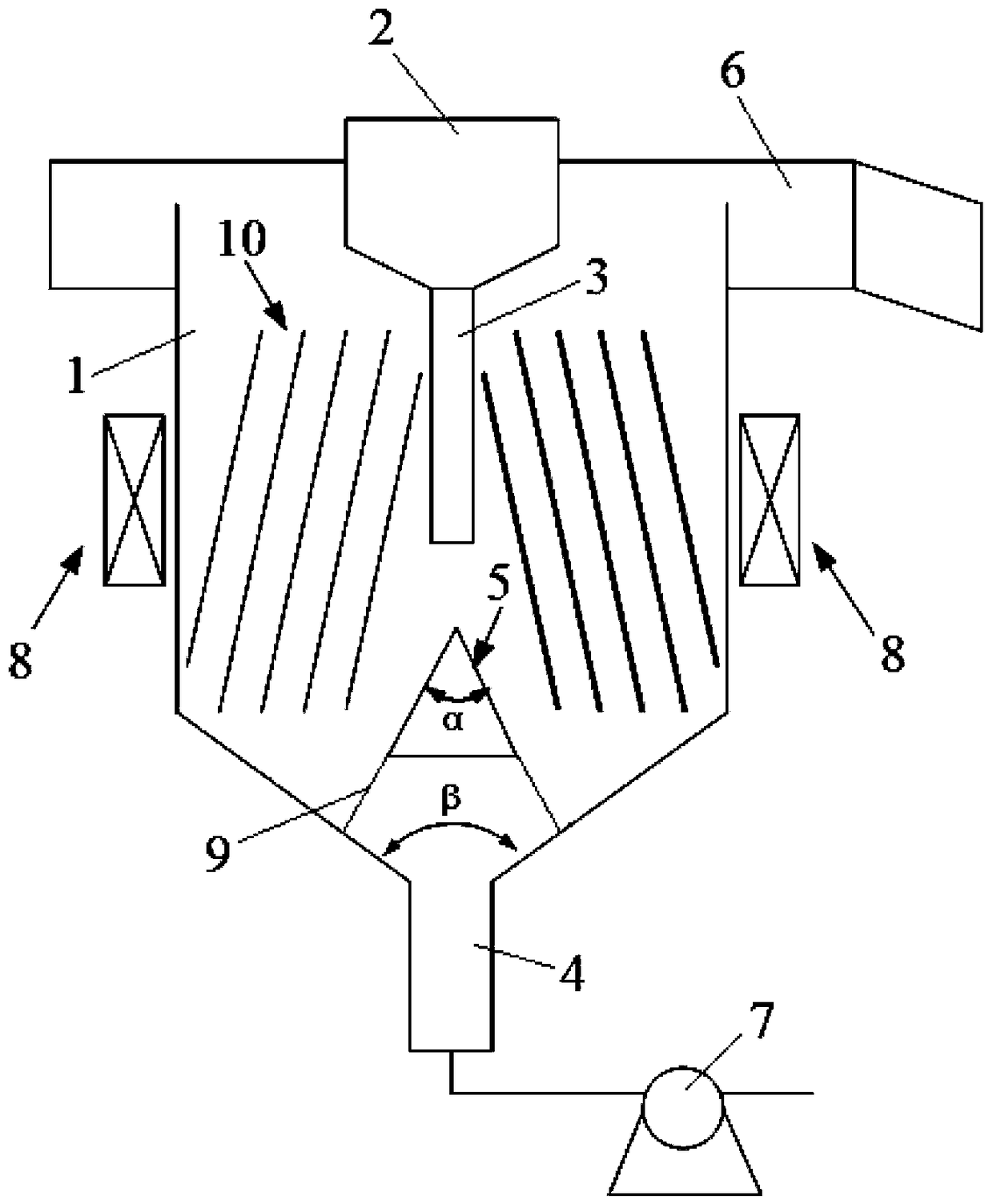

A fluid continuous sedimentation reactor for removing iron and impurities

A reactor and continuous technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of incomplete removal of impurities, long-term action time, difficult operation, etc. Achieve fast and efficient iron and impurity removal, short action time, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Use this reactor to process Fe 3+ The copper sulfate leaching solution with a content of 6.67g / L, after the leaching solution is added with medicines to adjust the slurry, is connected to the continuous sedimentation reactor for iron and impurity removal of this fluid for sedimentation. After the above treatment, the precipitate quickly settled within one minute, the precipitate was easy to filter, and the Fe in the supernatant 3+ down to 2.95mg / L.

Embodiment 2

[0033] Use this reactor to process Fe3+ The copper sulfate leaching solution with a content of 13.4g / L, after the leaching solution is added with medicines to adjust the slurry, is connected to the continuous sedimentation reactor for iron and impurity removal of this fluid for sedimentation. After the above treatment, the precipitate quickly settled within five minutes, the precipitate was easy to filter, and the Fe in the supernatant 3+ down to 3.15mg / L.

Embodiment 3

[0035] Use this reactor to process Fe 3+ The zinc sulfate solution with a content of 5.8g / L, after the leaching solution is added with drugs to adjust the slurry, is connected to this fluid continuous sedimentation reactor for iron and impurity removal for sedimentation. After the above treatment, the precipitate quickly settled within one minute, the precipitate was easy to filter, and the Fe in the supernatant 3+ down to 2.16mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com