A magnetostrictive guided wave transducer

A magnetostrictive and transducer technology, applied in the direction of material magnetic variables, etc., can solve the problems of low detection efficiency, inconvenient disassembly and assembly, and complicated steps, and achieve the effects of high detection efficiency, convenient disassembly and assembly, and a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

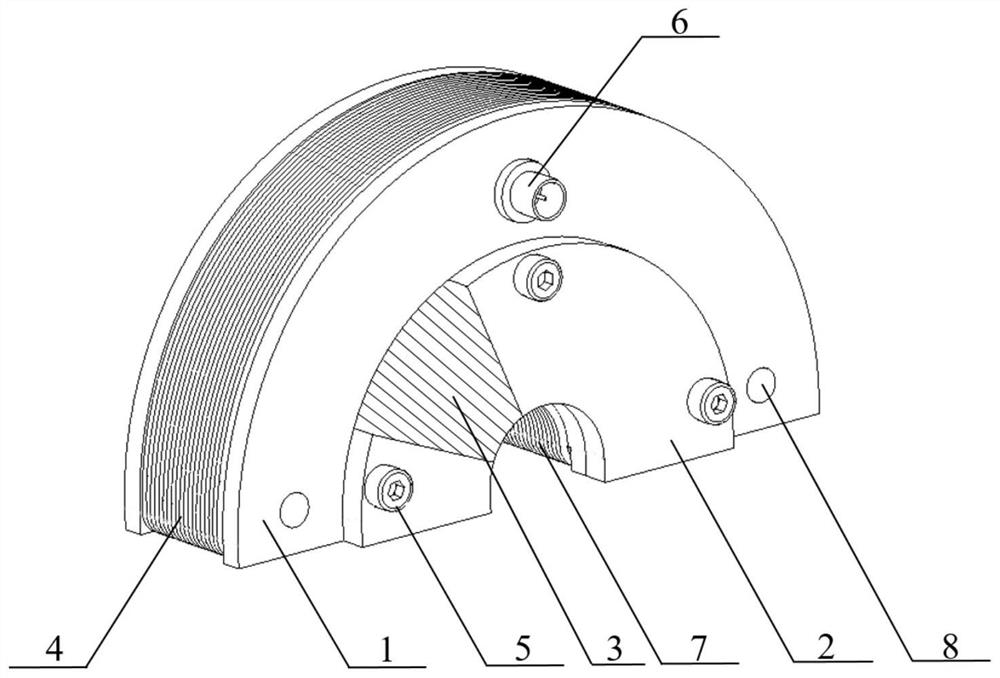

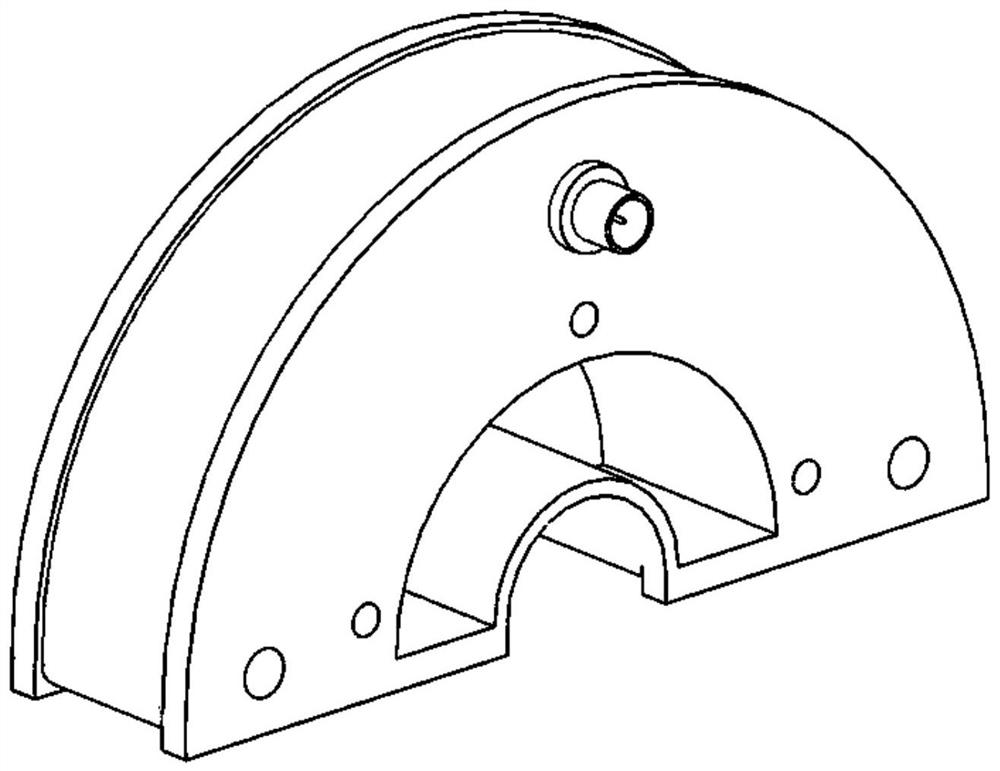

[0043] The component 10 to be tested is a steel pipe made of No. 20 steel, with an outer diameter of 20 mm, a wall thickness of 1 mm, and a length of 2500 mm. Both the transducer at the excitation end and the transducer at the receiving end use semi-cylindrical magnetostrictive guided-wave transducers, and the skeleton 1 and protective shell 2 of the semi-cylindrical magnetostrictive guided-wave transducer are made of photosensitive resin , the thickness is 30mm, the diameter of the outermost large circle of skeleton 1 is 122mm, the diameter of the innermost small circle is 24mm, the inner diameter of the protective shell is 24mm, the outer diameter is 68mm, and the thickness is 5mm; Composed of magnets, the permanent magnet 3 has an inner diameter of 28mm, an outer diameter of 58mm, and a thickness of 30mm. The magnetization direction is as follows: Figure 5As shown; the inner solenoid coil 7 is wound by an enameled wire with a wire diameter of 1.08 mm, the number of turns i...

Embodiment 2

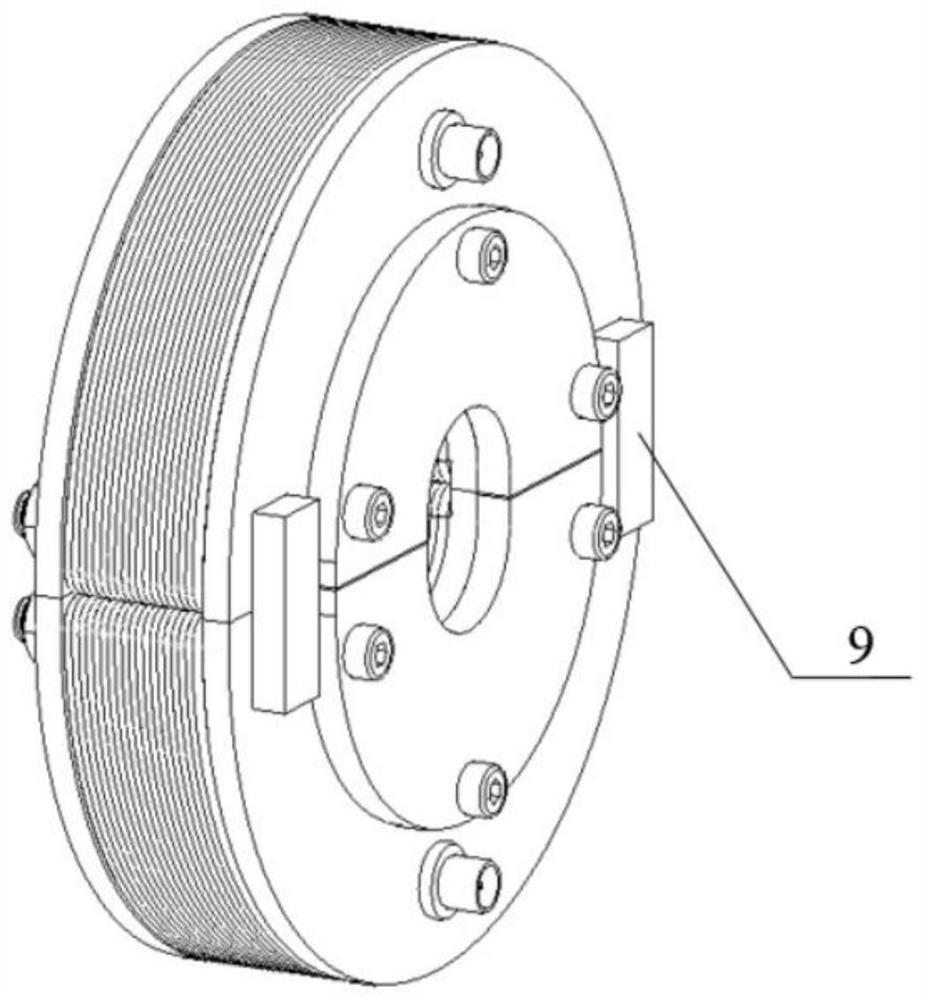

[0046] Both the transducer at the excitation end and the transducer at the receiving end use cylindrical magnetostrictive guided wave transducers, and each cylindrical magnetostrictive guided wave transducer consists of two semi-cylindrical magnetostrictive guided wave transducers Assembled, the parameters of the semi-cylindrical magnetostrictive guided wave transducer and the member to be tested 10 are the same as those in Embodiment 1.

[0047] The cylindrical magnetostrictive guided wave transducers at the excitation end and the receiving end are installed and arranged as follows: Figure 8 and Figure 10 As shown, the transducers at both ends are connected by joint 6, the transducer at the excitation end is 1000 mm away from the left end of the steel pipe, and the transducer at the receiving end is 1000 mm away from the right end of the steel pipe. During work, adopt the same signal acquisition step as in embodiment 1, the received signal that gathers is as follows Figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com