Magnetic steel fixing frame for magnetor rotor

A fixed frame and magneto technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of ineffective magnetization, plastic is not easy to be covered, and the fixation is not firm, so as to facilitate effective charging Reliable effect of magnetic and magnetic steel fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

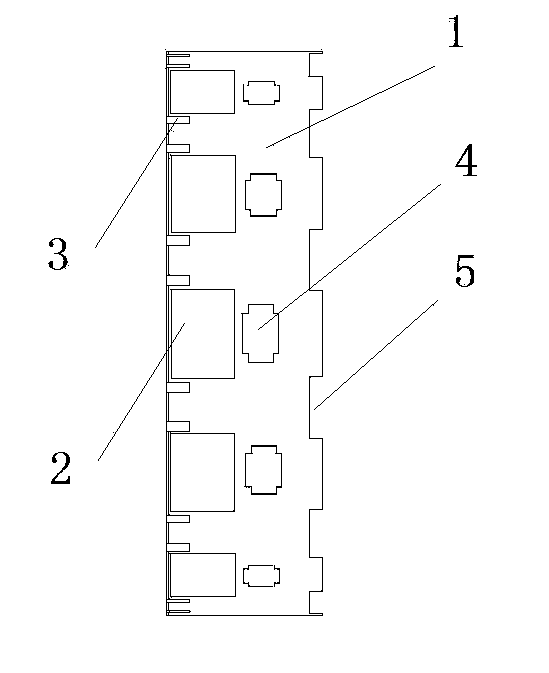

[0013] Referring to the accompanying drawing 1, the magnetic steel fixing frame 1 for the magneto rotor shown in the embodiment of the present invention is a ring-shaped member with a plurality of grooves 5 on its edge, and there are two positions for fixing the magnetic steel 2 in the fixing frame. There is a fixed card 3 on the side, and a plurality of windows 4 are also opened on the fixed frame. They are all located on one side of each magnet 2 and in the middle of the ring, and the position of each window corresponds to the position of each magnet 4. Magnetic steel 2 is fixed on the magnetic steel fixed frame 1 by fixing card 3, and plastics easily enters from each window 4 and is covered with the inside of magnetic steel fixed frame during injection molding, and magnetic steel is fixed reliably. Each window accurately indicates the position of each magnet during magnetization, which is convenient for effective magnetization.

[0014] The above drawings and embodiments ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com