A cam-type method and device for tearing and cutting grass

A cam type and cam technology, which is applied in the field of grass tearing and cutting methods and devices, can solve the problems of easy damage to forage or turf roots, and achieve the effect of uniform distribution of growth nodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

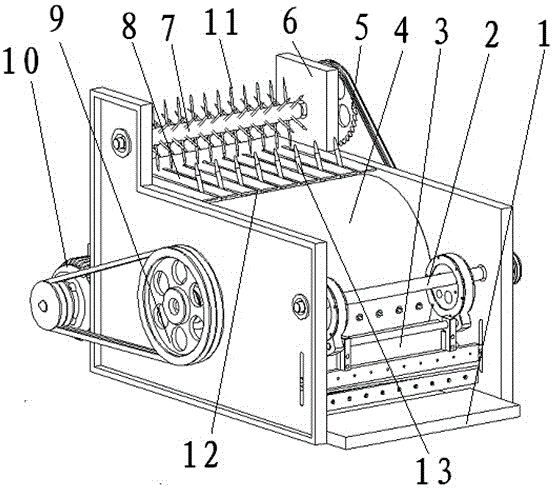

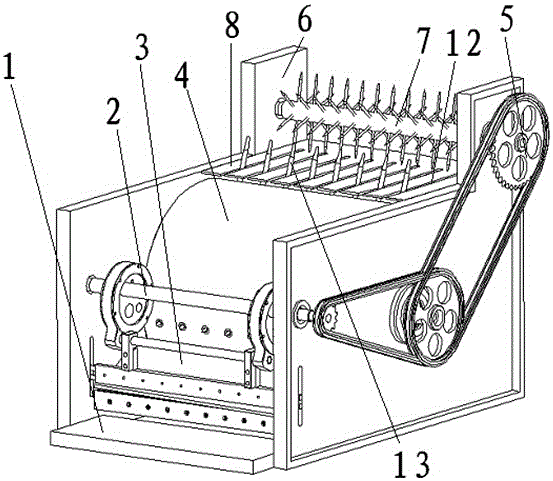

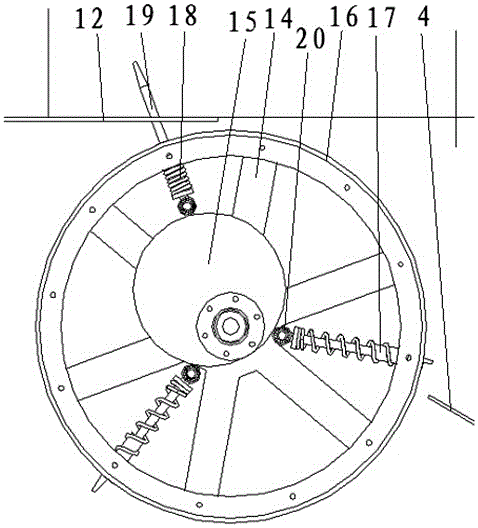

[0028] attached figure 1 A technical embodiment of the present invention is given. As can be seen from the accompanying drawings, the present invention is a cam-type grass tearing and cutting device, including a separation device delivery platform 8, the separation device delivery platform 8 is installed on two supports 6, and a low-speed motor is installed above the separation device delivery platform 8 The feeding device 7 is equipped with a cam tearing mechanism 13 under the conveying platform 8 of the separating device, and the forage or turf enters the separating device along the conveying platform 8 of the separating device under the drive of the low-speed feeding device, and is torn by the cam tearing mechanism. split apart.

[0029] The low-speed feeding device 7 is a cylindrical columnar body, and the two ends of the cylindrical columnar body are installed on the support 6, located above the separation device delivery platform 8, and there are feeding spikes 11 on th...

Embodiment 2

[0037] The basic principle of embodiment two is the same as that of embodiment one, but in structure, the described cam tearing grass mechanism is installed above the separator conveying platform, behind the low-speed feeding device; and the cam tearing grass Mechanism spikes are pierced from above the material, and are torn and separated by moving speed difference. Doing so can prevent soil from falling into the cam tearing mechanism and improve the working stability of the cam tearing mechanism.

[0038] It can be seen from the above embodiments that the present invention relates to a cam-type grass tearing and cutting method, which uses a low-speed feeding device to feed the grass or turf into the separation device, and then extends the separation spikes through the cam grass tearing mechanism to insert the grass or turf, at the same time, the cam tearing mechanism drives the inserted forage or turf to move, and the cam tearing mechanism stretches out the separation spikes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com