A kind of preparation method and application of enzymolysis butter

An enzymatic hydrolysis and butter technology, which is applied in the application and extraction of butter, dairy products, etc., can solve the problems of weak flavor and weak taste of the final product, and achieve the effects of enhancing flavor, increasing value, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

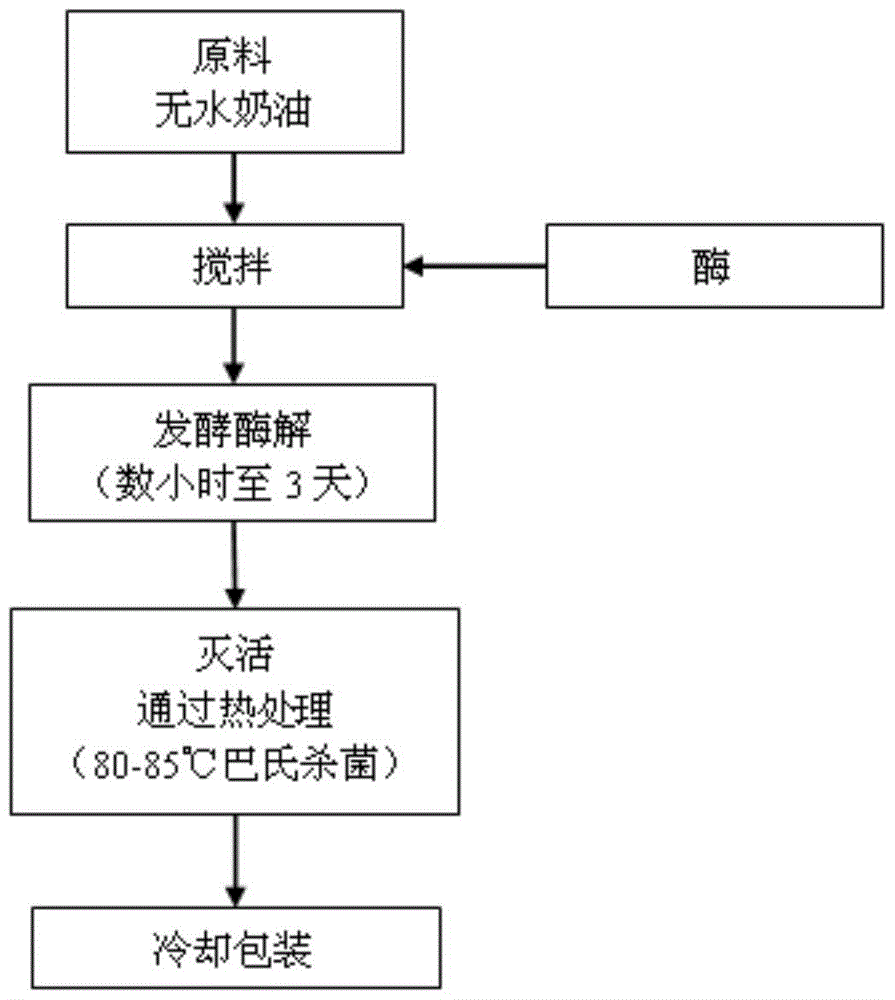

[0029] combined with figure 1 , enzymolysis butter is prepared according to the following steps:

[0030] (1) Heat 3kg of anhydrous butter to 33°C, stir to melt it completely, use 0.1mol / L NaOH solution and 0.1mol / L HCl solution to adjust the pH to 7.30, take out 100g of melted anhydrous butter at 40°C Water bath insulation spare;

[0031] (2) Weigh 1g Lipase AY.30 and 4g Lipase R, add it to 100g liquid anhydrous cream for standby heating in a water bath, stir until the lipase is completely dissolved, and then add it to the base material;

[0032] (3) Heat anhydrous butter to 46°C, stir at a low speed of 20r / min, enzymatically hydrolyze for 5 hours, heat to 80°C for 20 minutes after the reaction, add lactic acid to adjust the pH to 3.5, then cool and pack to obtain the finished product.

Embodiment 2

[0034] combined with figure 1 , enzymolysis butter is prepared according to the following steps:

[0035] (1) Heat 3kg of anhydrous butter to 43°C, stir to melt it completely, use 0.1mol / L NaOH solution and 0.1mol / L HCl solution to adjust the pH to 7.30, take out 100g of melted anhydrous butter at 40°C Water bath insulation spare;

[0036] (2) Weigh 12g Lipase AY.30 and 3g Lipase R, add to 100g liquid anhydrous cream for standby heating in a water bath, stir until the lipase is completely dissolved, then add to the base material;

[0037] (3) Heat anhydrous butter to 45°C, stir at a low speed of 30r / min, enzymatically hydrolyze for 30 hours, heat to 85°C for 20 minutes after the reaction, add lactic acid to adjust the pH to 3.5, then cool and pack to obtain the finished product.

Embodiment 3

[0039] combined with figure 1 , enzymolysis butter is prepared according to the following steps:

[0040] (1) Heat 3kg of anhydrous butter to 38°C, stir to melt it completely, use 0.1mol / L NaOH solution and 0.1mol / L HCl solution to adjust the pH to 7.30, take out 100g of melted anhydrous butter at 40°C Water bath insulation spare;

[0041] (2) Weigh 15g Lipase AY.30 and 10g Lipase R, add it to 100g liquid anhydrous butter for standby heating in a water bath, stir until the lipase is completely dissolved, and then add it to the base material;

[0042] (3) Heat anhydrous butter to 46°C, stir at a low speed of 40r / min, enzymatically hydrolyze for 72 hours, heat to 82°C for 20 minutes after the reaction, add lactic acid to adjust the pH to 3.5, then cool and pack to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com