Trap

A technology for steam traps and valve bodies, which can be used in steam traps, mechanical equipment, etc., and can solve the problems of large volume, high manufacturing cost, and heavy quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

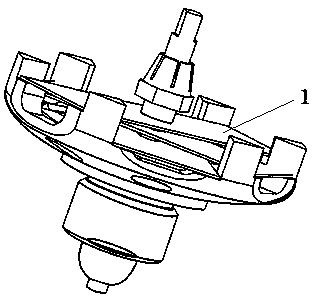

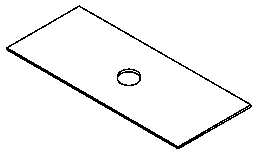

[0011] Such as figure 1 As shown, the steam trap of the present invention includes a valve body, the upper end surface of the valve body is fixed with a valve cover by external bolts, and a valve stem assembly is arranged in the valve body. A valve core frame is fixed in the valve body, and a metal sheet assembly is connected to the valve core frame through inner bolts, and the valve stem assembly passes through the valve core frame and is fixed on the metal sheet assembly. The shape of the metal sheet 1 is rectangular, and it is designed to be used in combination of three metal sheets 1 according to the operating pressure of the trap, the condensate discharge temperature and the discharge capacity. The thermal pulling force generated by the heating of the metal sheet 1 independently acts on the valve stem assembly, so that the steam trap stops discharging. Each metal piece 1 participates in the work sequentially according to the pressure range applied by the metal trap, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com