Method for detecting shock-absorption and noise-reduction performance of car damping material

A damping material, vibration reduction and noise reduction technology, applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve problems such as unsatisfactory vibration and noise reduction effects, large structural energy damping coefficients, and result errors, and achieve results Intuitive and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

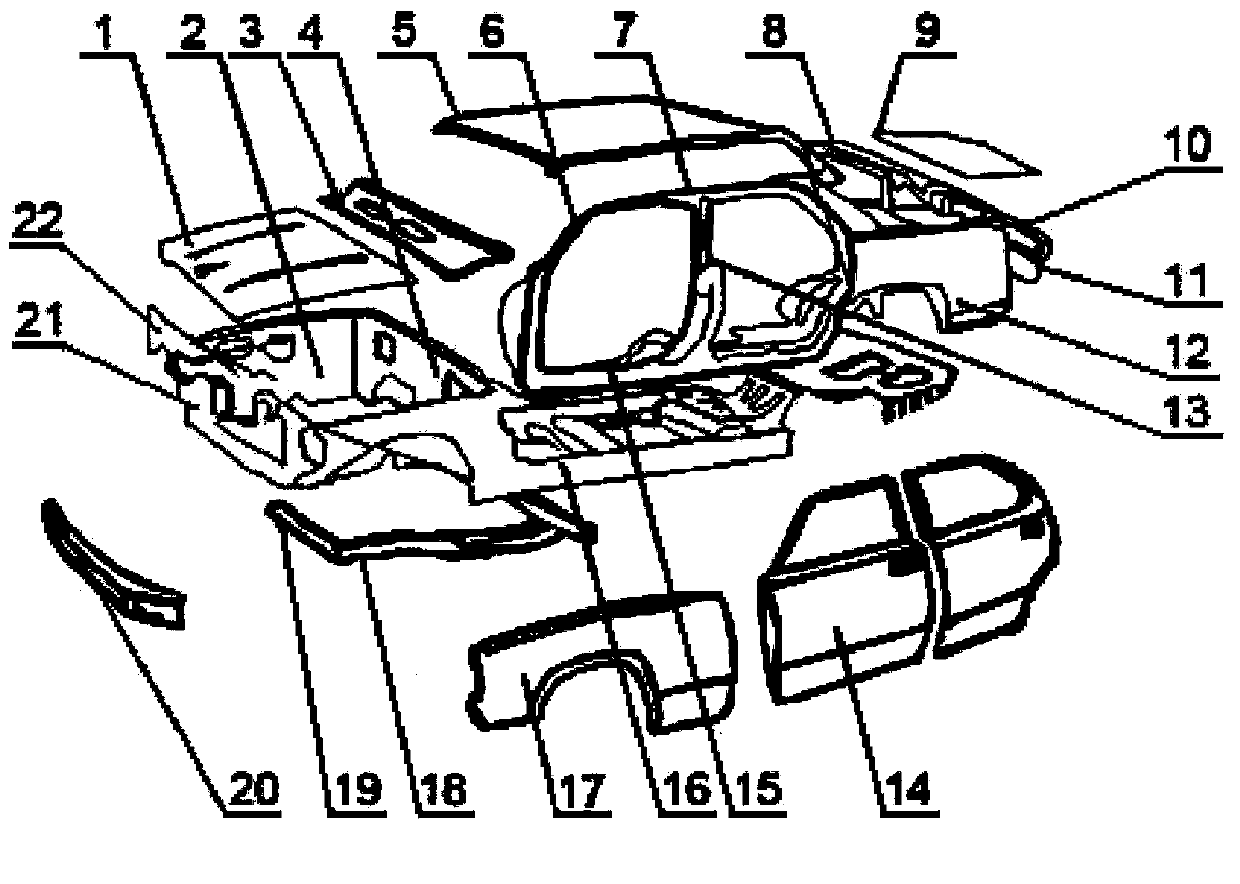

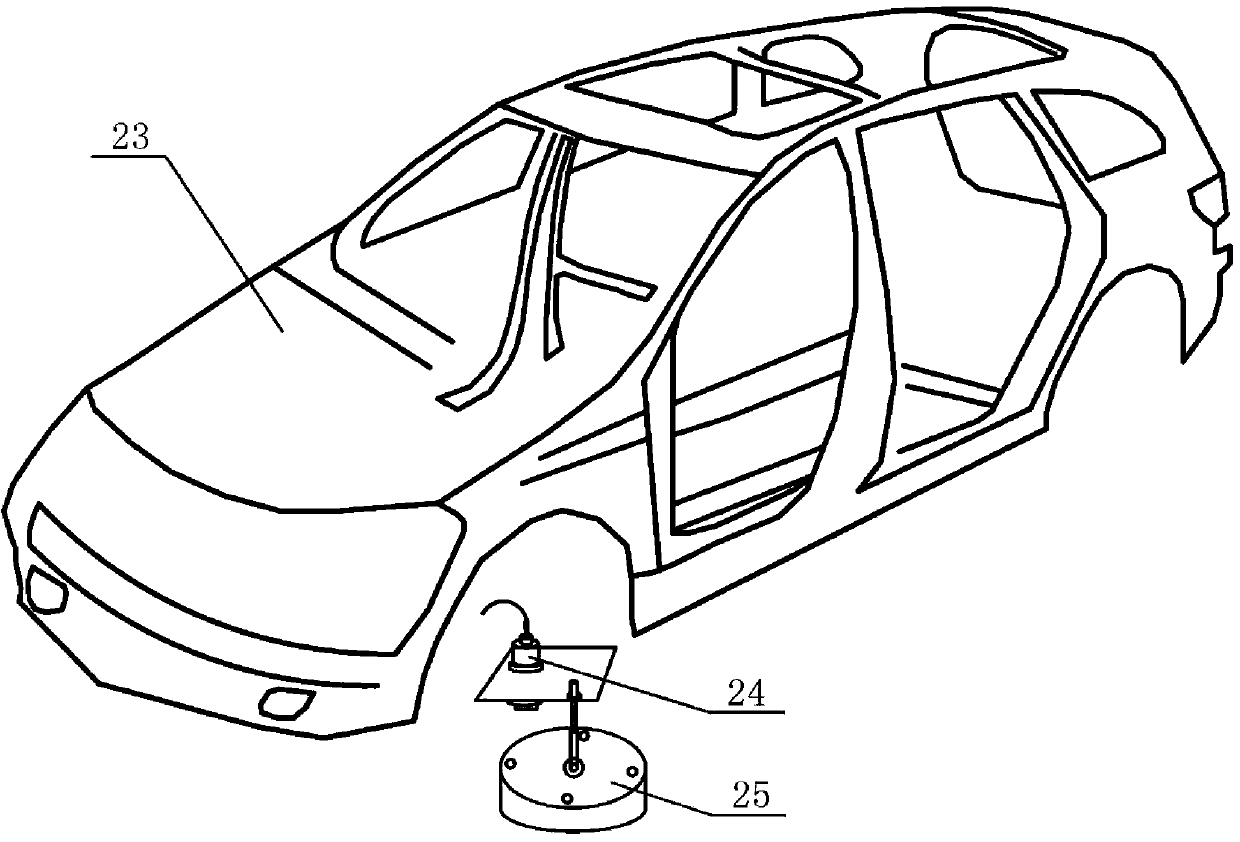

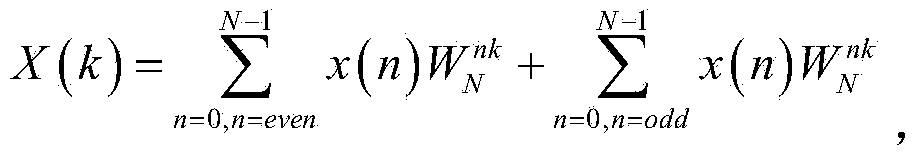

Method used

Image

Examples

Embodiment 1

[0040] A certain brand of automobile was selected, and the damping composite material 1 was selected for vibration and noise reduction performance testing. The damping composite material 1 was the product of Example 1 with application number: 201310077414.X, that is, 600 grams of polysiloxane matrix was added to a 2.5L reactor Resin, such as polydimethylsiloxane, etc., 6 grams of organic bentonite, 60 grams of oligomeric polyester polyol with a number average molecular weight of 100, 300 grams of silicone oil, 120 grams of silica powder with a particle size of 50 microns and 50 microns Mix 120 grams of micron glass microspheres evenly and add them to the reaction kettle together with 12 grams of antioxidants, stir at a stirring speed of 120 raund / min, and program temperature rise at the same time at a rate of 5°C / min. Knead at 120°C for 30-90min and extrude to granulate. The vibration damping of the resulting elastomer at 25°C and 60°C was 17 and 22, and the vibration damping ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com