Patents

Literature

54results about How to "Simplify inspection work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

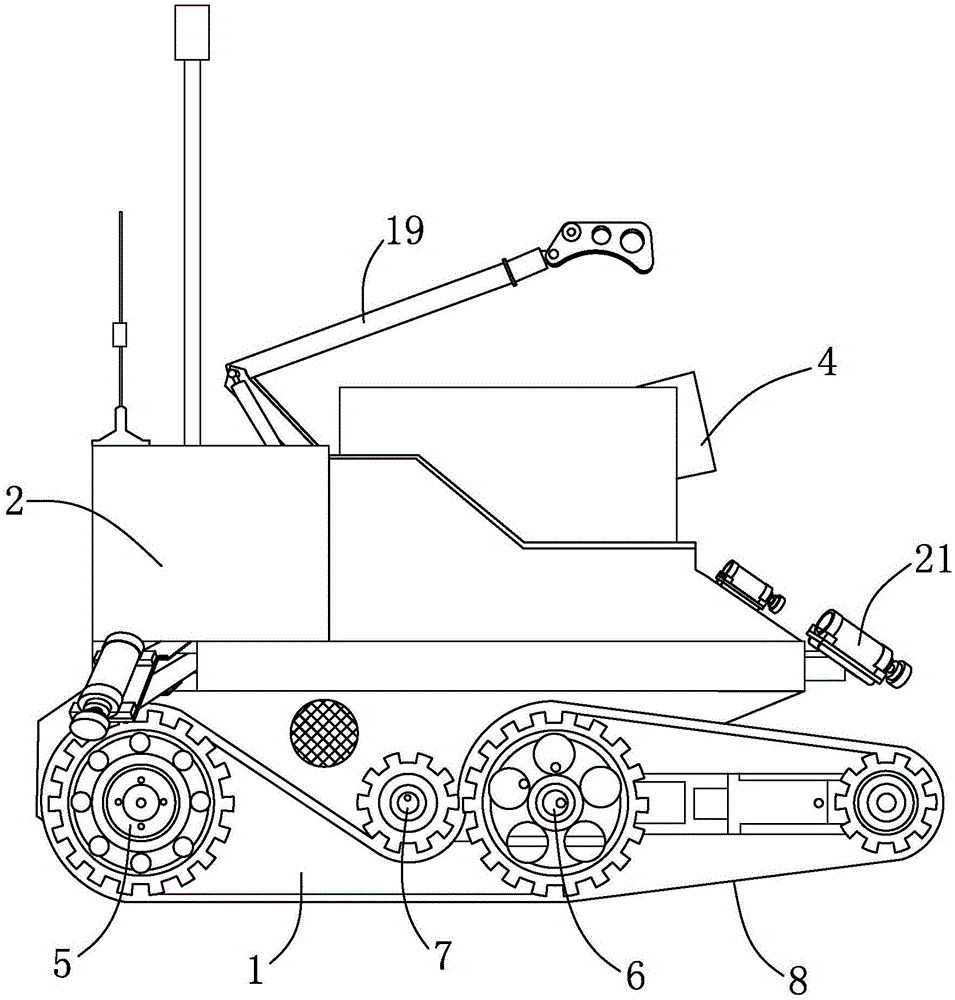

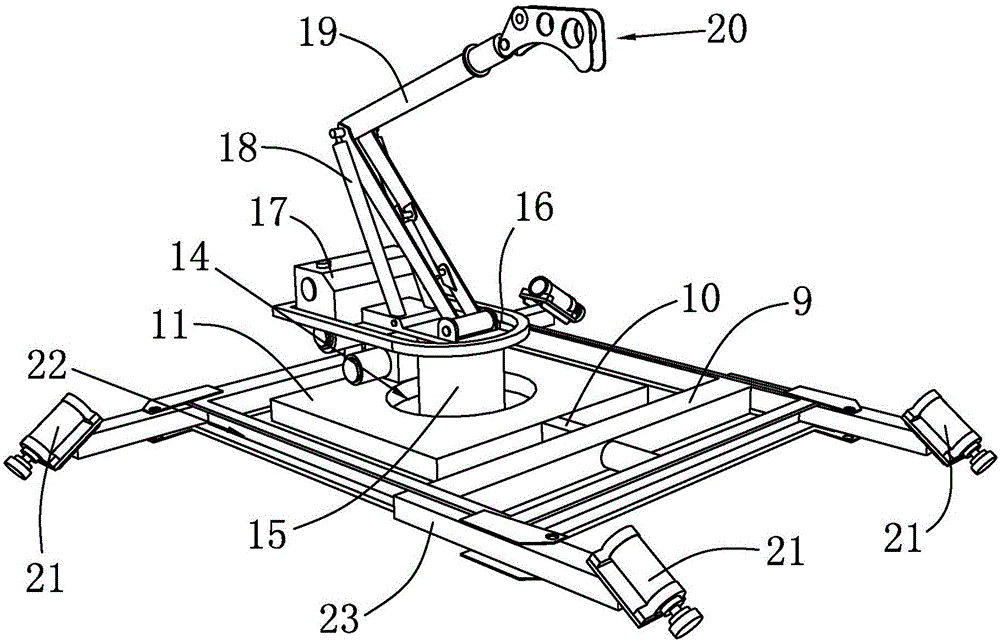

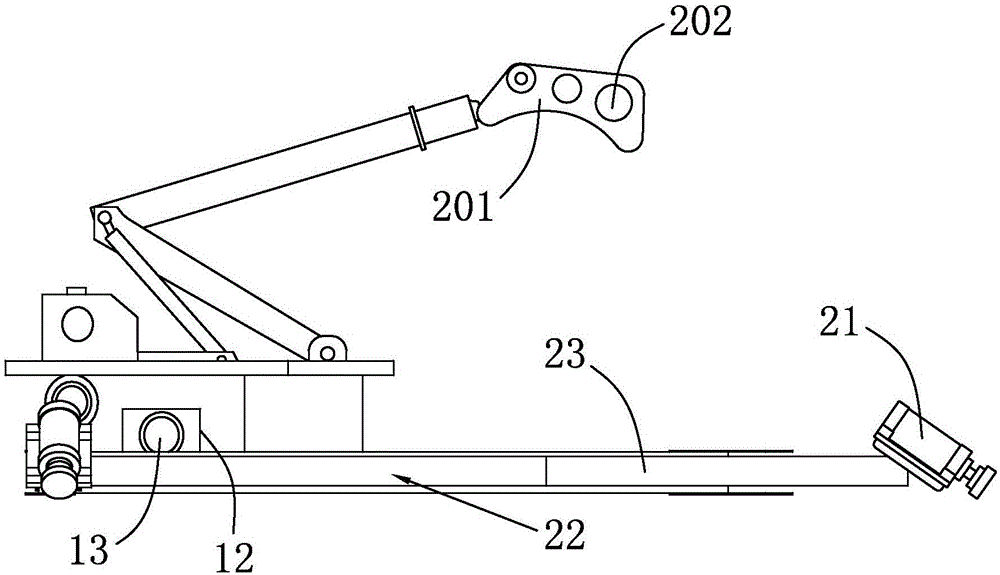

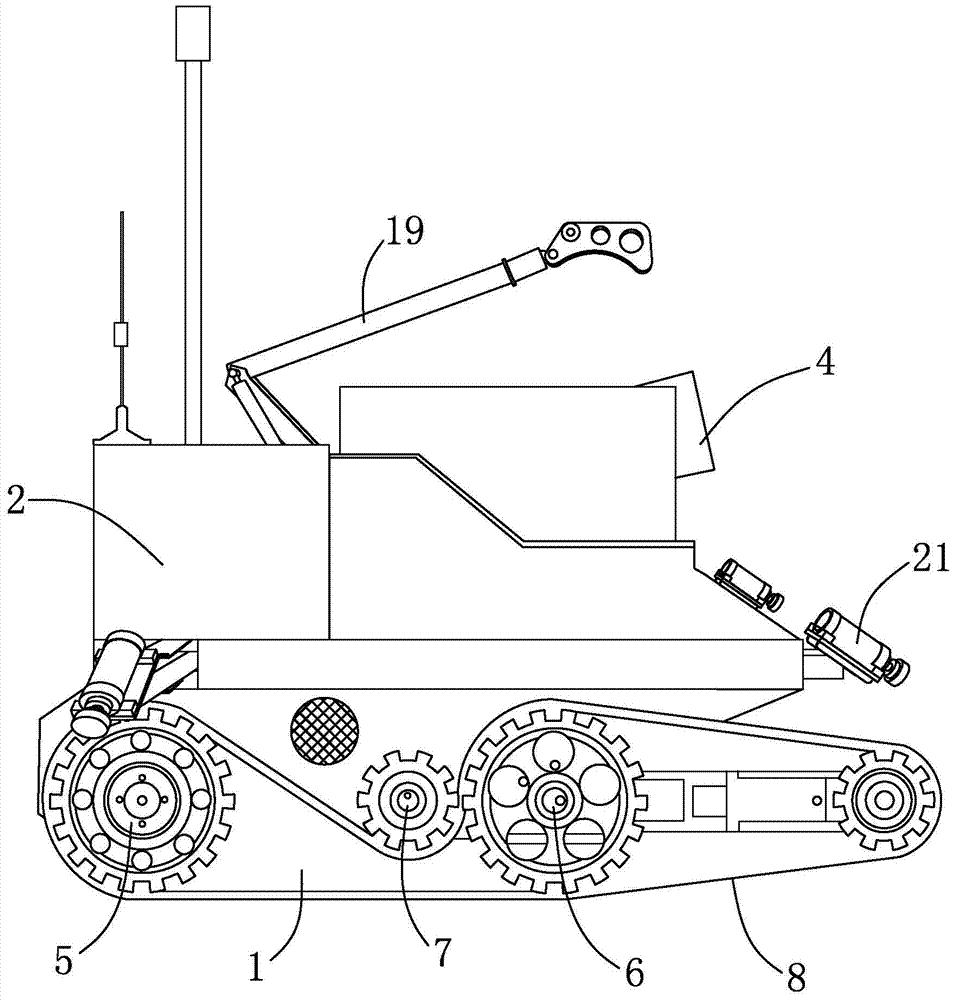

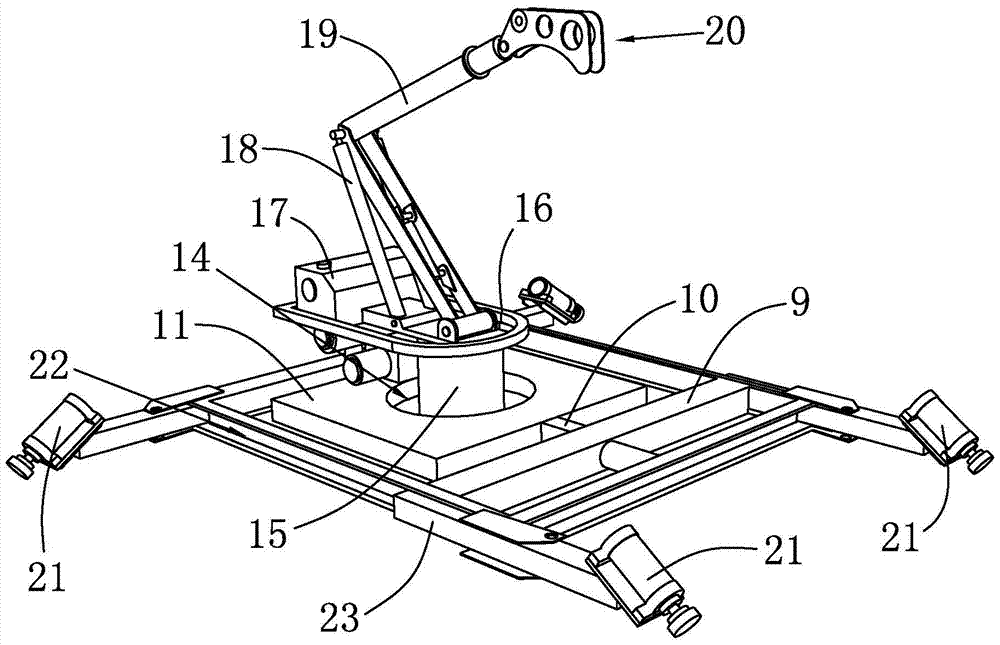

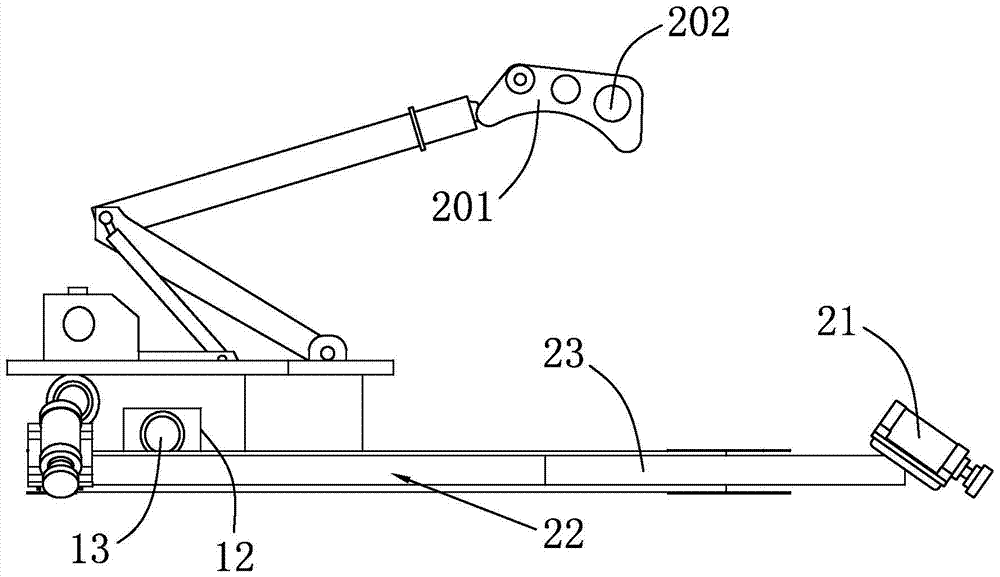

Tunnel detection robot and detection method

ActiveCN105082180AImprove obstacle performanceImprove environmental adaptabilityMeasurement devicesManipulatorEngineeringInformation data

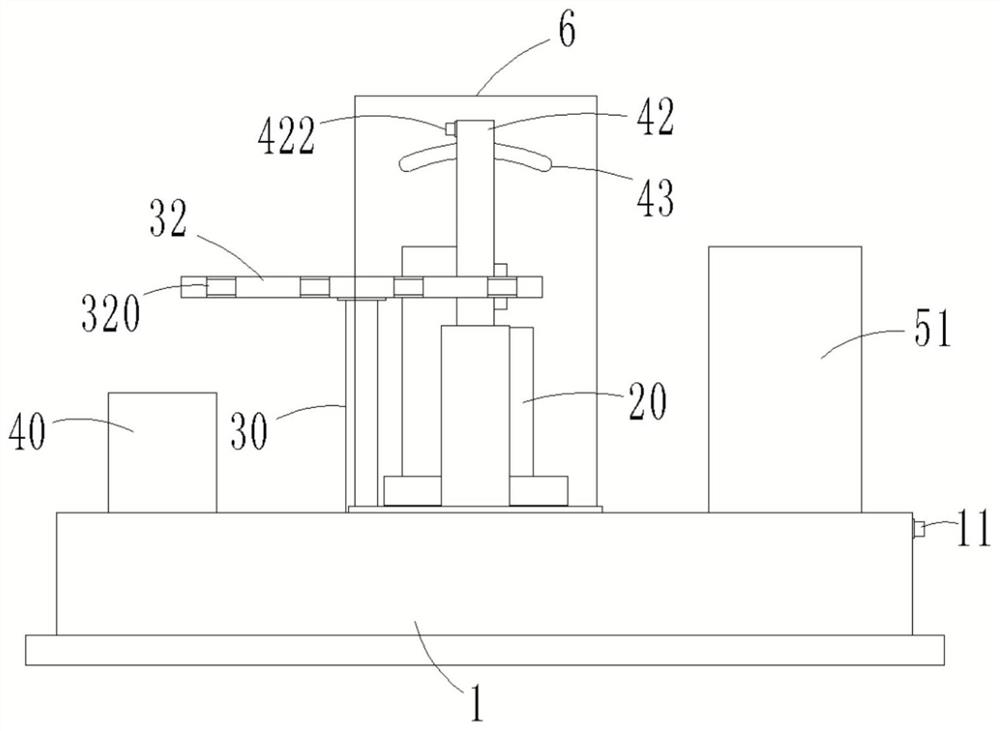

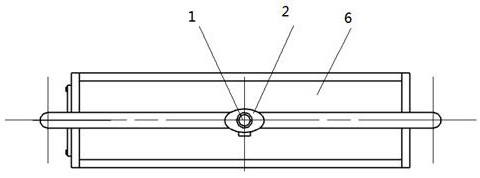

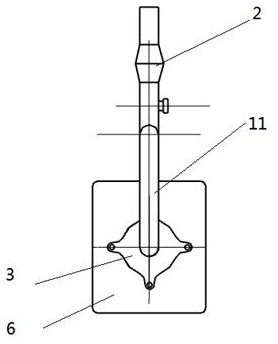

The invention discloses a tunnel detection robot and a detection method. A moving platform on the tunnel detection robot is provided with a supporting mechanism. A moving mechanism is arranged on the supporting mechanism and provided with a rotating mechanism. The rotating mechanism is provided with a base. A drive arm is arranged on the base. A rotating mechanical arm is arranged on the base. The rotating mechanical arm is provided with a jacking mechanism. The detection method of the tunnel detection robot comprises the following steps of (a) establishing a tunnel information work station, (b) measuring tunnel portal data, (c) lifting the tunnel detection robot, (d) locating the initial position of the tunnel detection robot, (e) obtaining tunnel detection information, (f) removing barriers in tunnel detection, (g) managing power in tunnel detection and (h) collecting and analyzing tunnel information. The tunnel detection robot has quite high obstacle climbing capacity and environment adaptive capacity and can obtain information data in the whole tunnel through one-time detection; and detection is rapid and simple, and detection precision is high.

Owner:HANGZHOU HUANENG SAFETY ENG POLYTRON TECH CO LTD

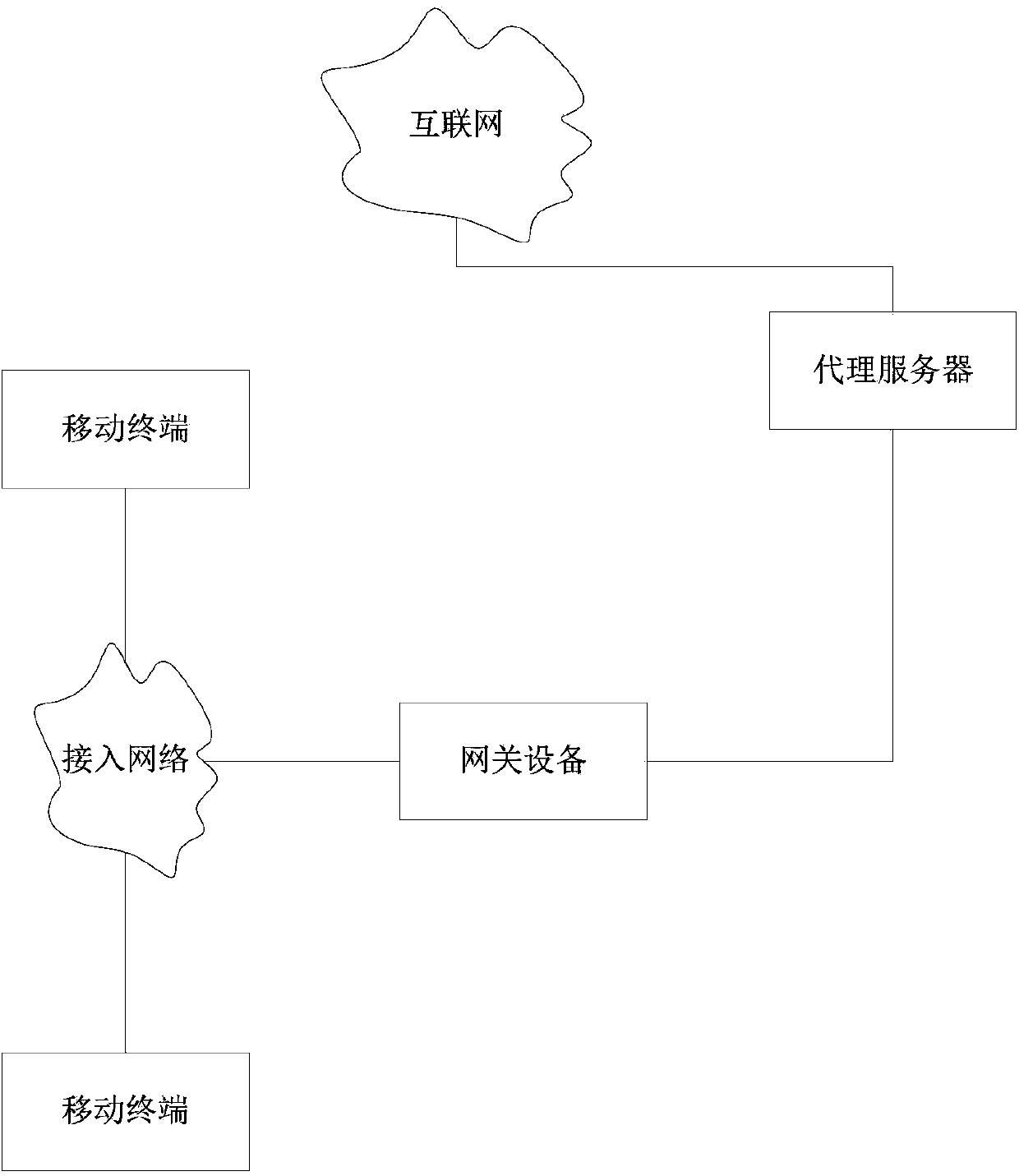

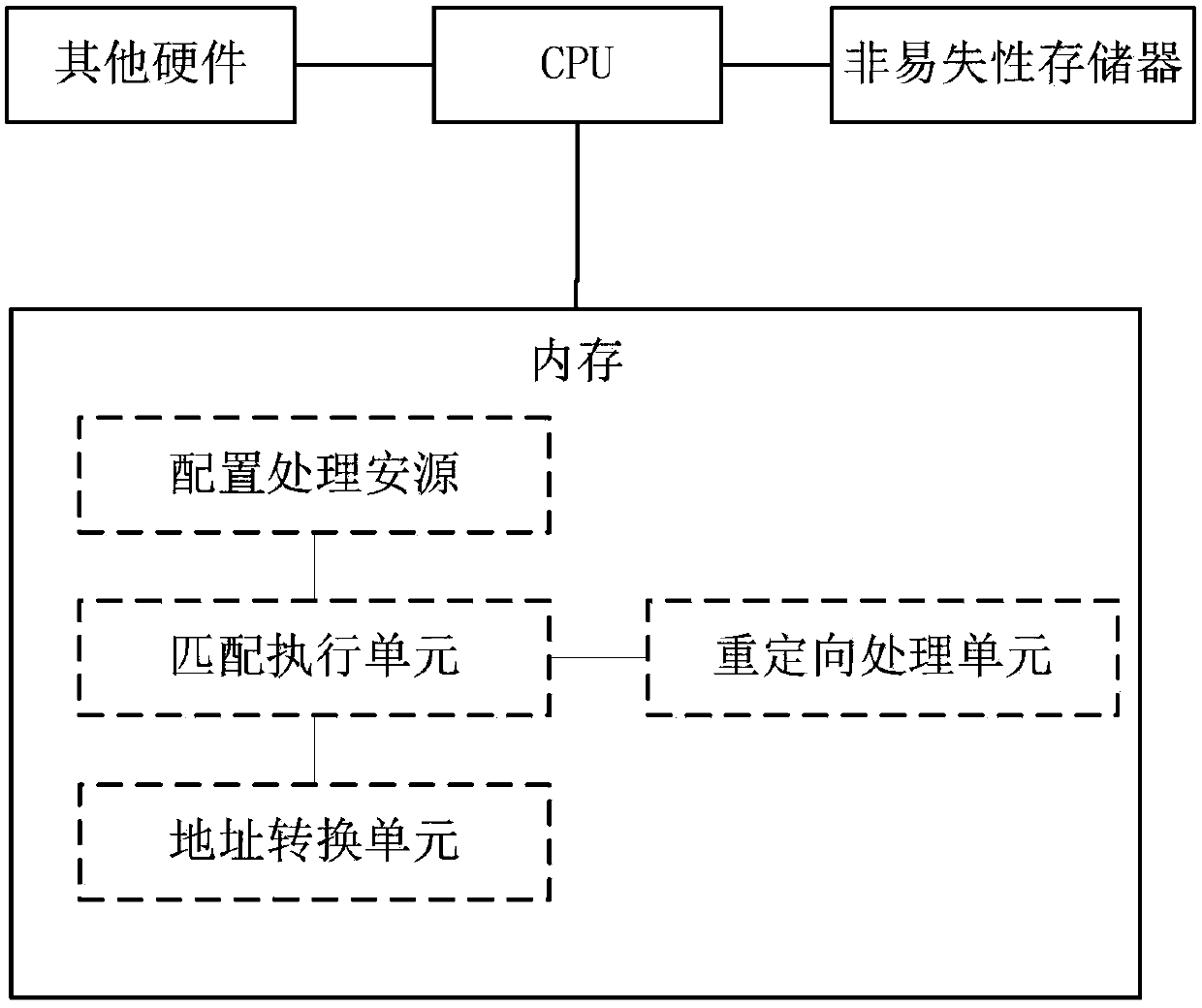

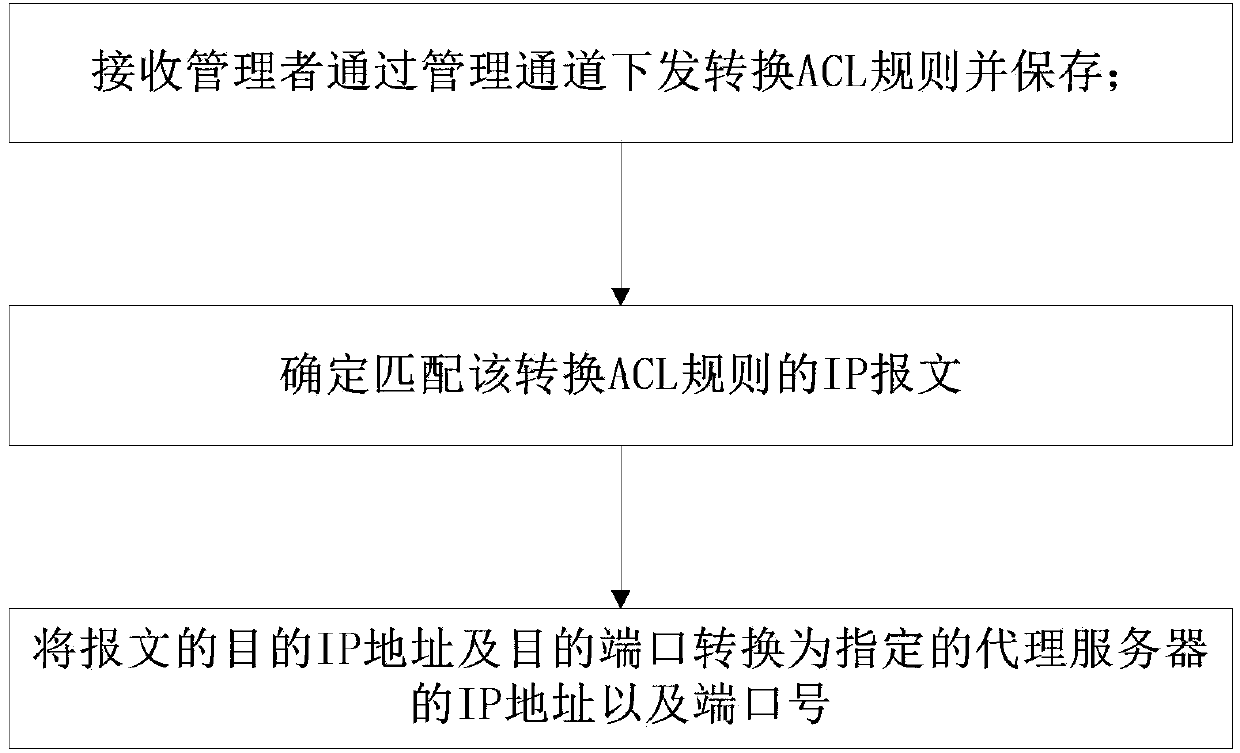

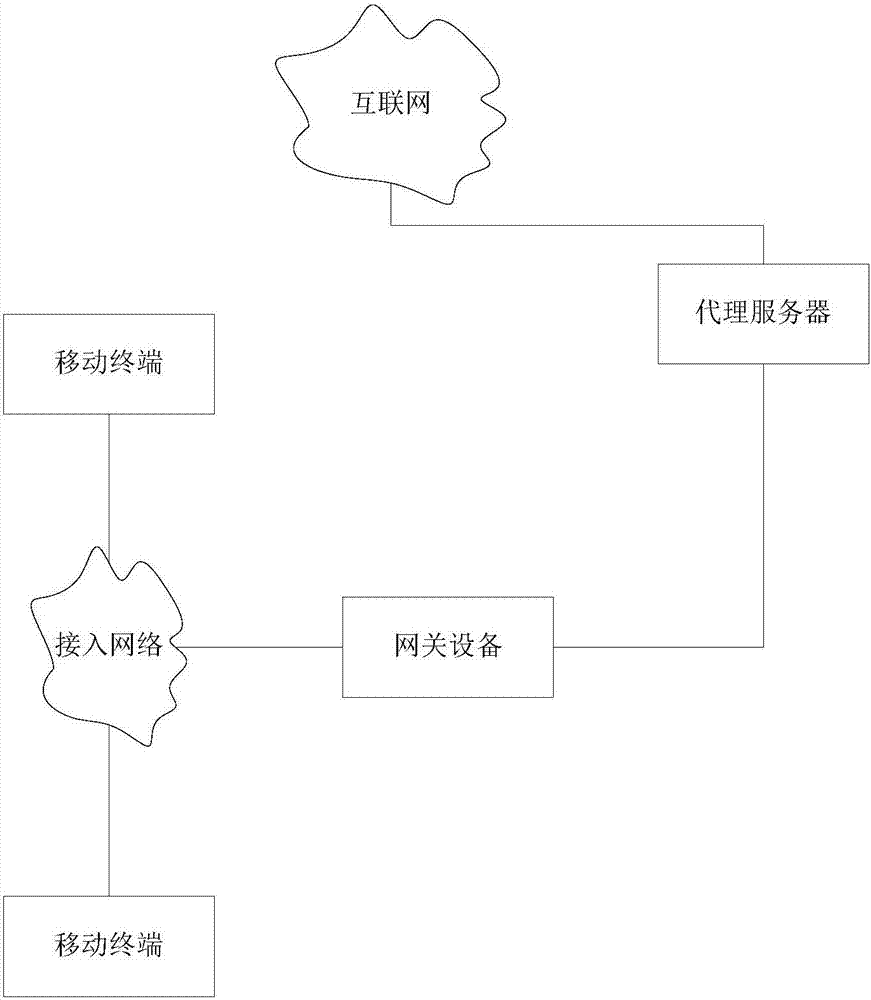

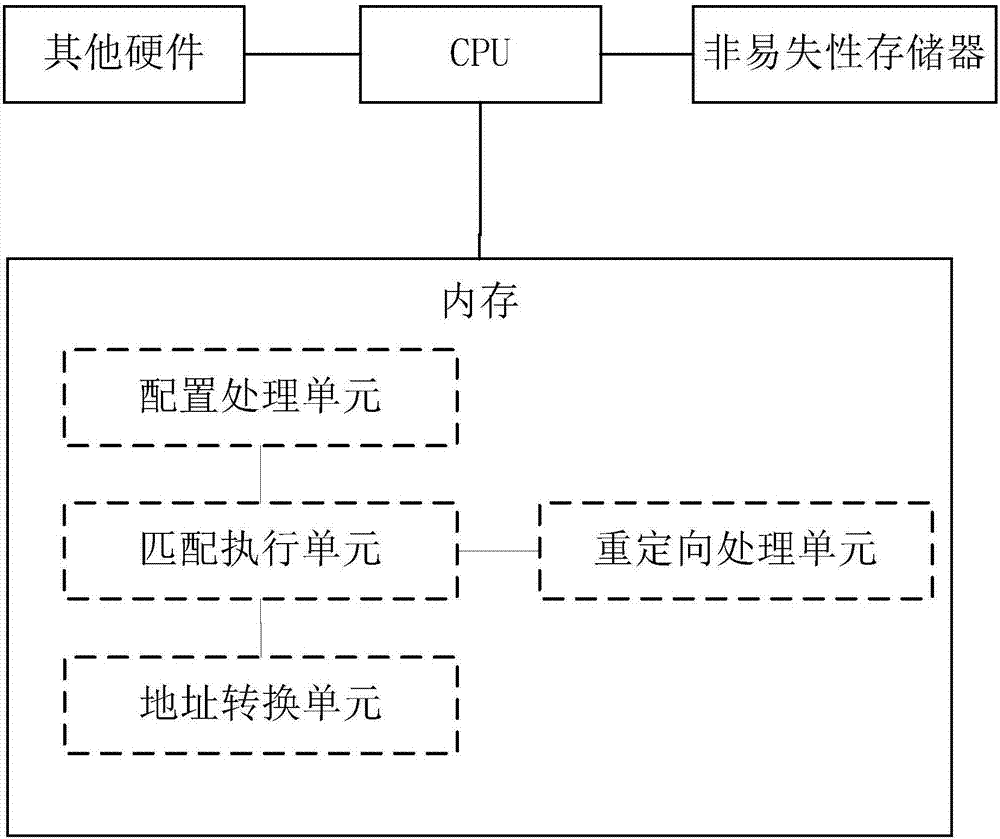

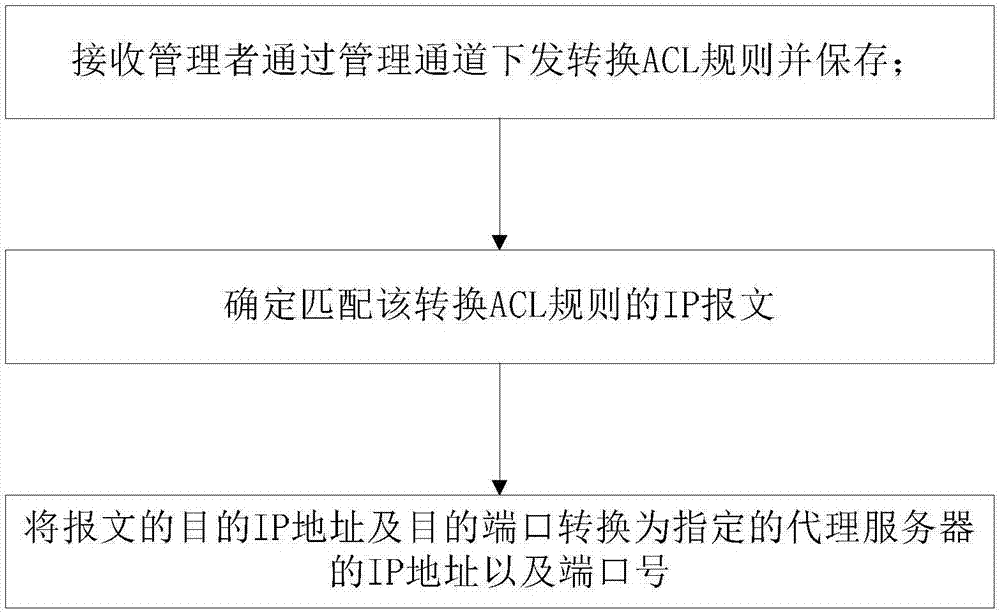

Terminal service method and apparatus

ActiveCN103475746ASimplify workSimplify the verification processTransmissionIp addressComputer terminal

The invention provides a terminal service method and device which are applied to network equipment arranged between a mobile terminal and an agent server. The method comprises the following steps: step A, receiving and storing a conversion ACL rule assigned by an administrator through a management channel, wherein the conversion ACL rule is used for filtering out an IP message which is specified by the administer and has a target IP address belonging to a specified network segment; step B, checking whether the IP message matches the conversion ACL rule, if so, skipping to step C for processing; and step C, correspondingly converting the target IP address and the destination port of the IP message into the IP address of a specified agent server and a specified port, and sending the modified IP message to the agent server. Compared to the prior art, by using the terminal service method and device, the work assigned by the NAT configuration of the administrator is greatly simplified, and the checking and inspection work of the administer in maintaining the NAT configuration can also be substantially simplified.

Owner:NEW H3C TECH CO LTD

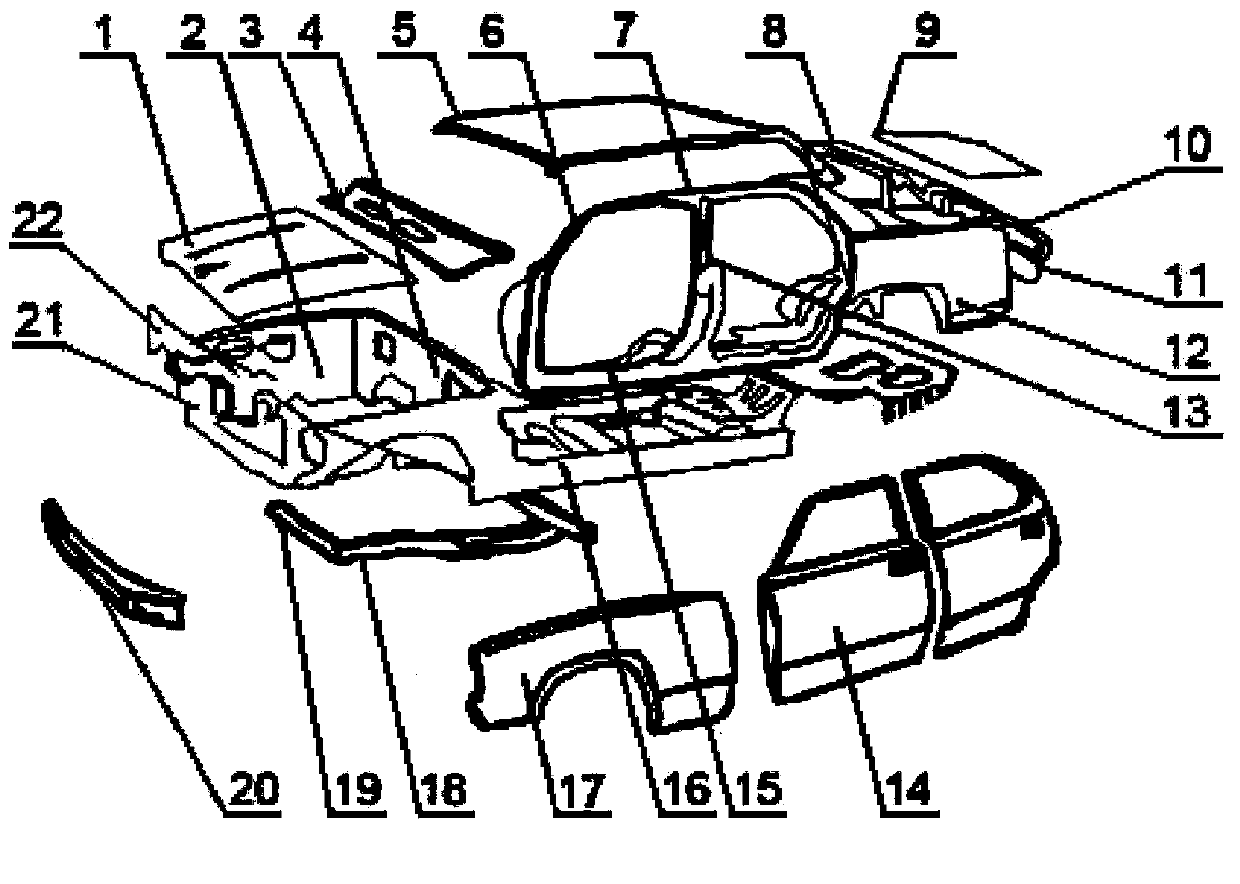

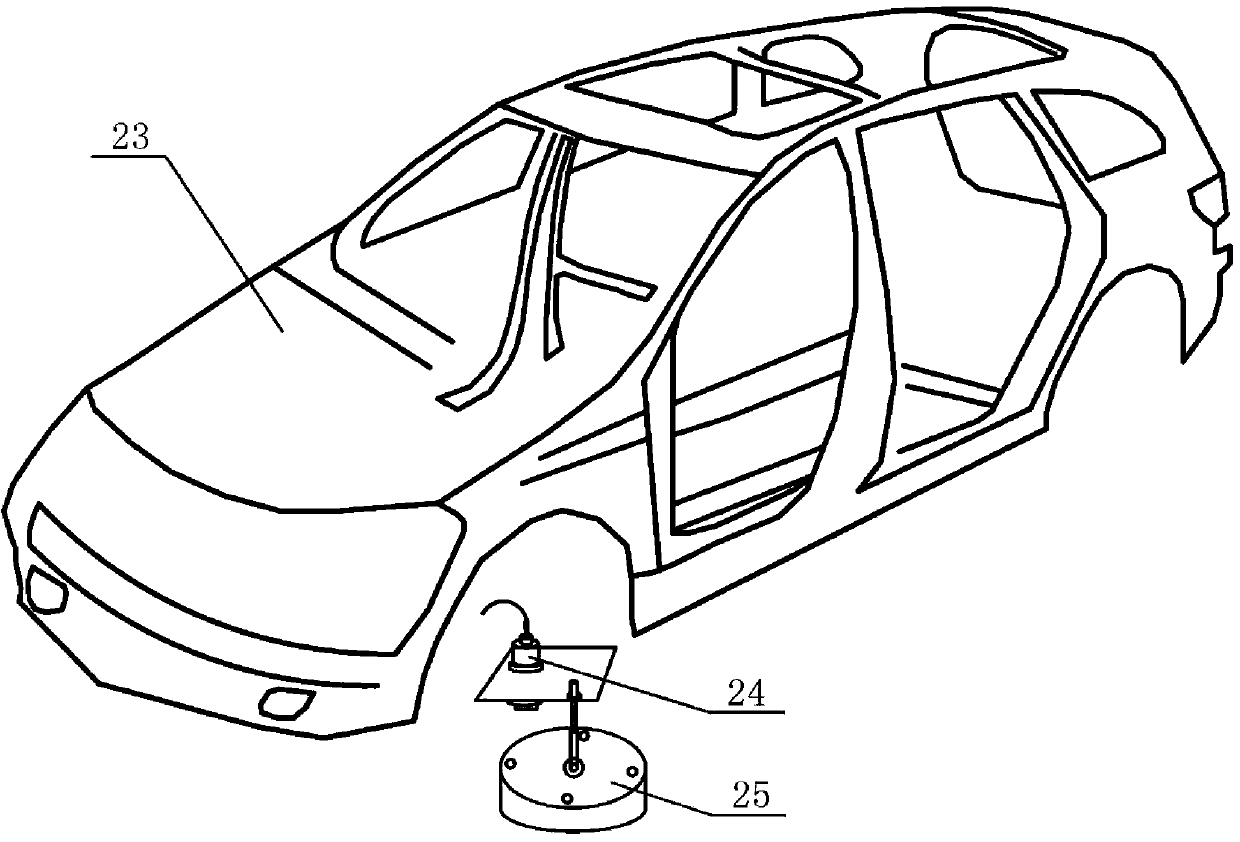

Method for detecting shock-absorption and noise-reduction performance of car damping material

ActiveCN104267104AEliminate the disadvantages of being separated from the actual car bodyReflect actual usageAnalysing solids using sonic/ultrasonic/infrasonic wavesPerformance indexEngineering

The invention discloses a method for detecting shock-absorption and noise-reduction performance of a car damping material. The method comprises detection on two aspects, i.e. the detection of a damping material on the aspect of the feeling of passengers for the vibration noise in the process of simulating the real driving process, and the detection of the damping material on the aspect of reducing the vibration of the overall structure of a car body and the bias of resonant frequency. By adopting a novel method for detecting the shock-absorption and noise-reduction performance of the damping material which is reasonably combined with the car body of a specific car, the shock-absorption performance index of the damping material applied to the car can be simply and intuitively expressed, the complicated modeling work can be omitted, the detection work is relatively simplified, the result is intuitive and dependable, and the application prospect is remarkable.

Owner:LIUZHOU XINGTA IND & TRADE

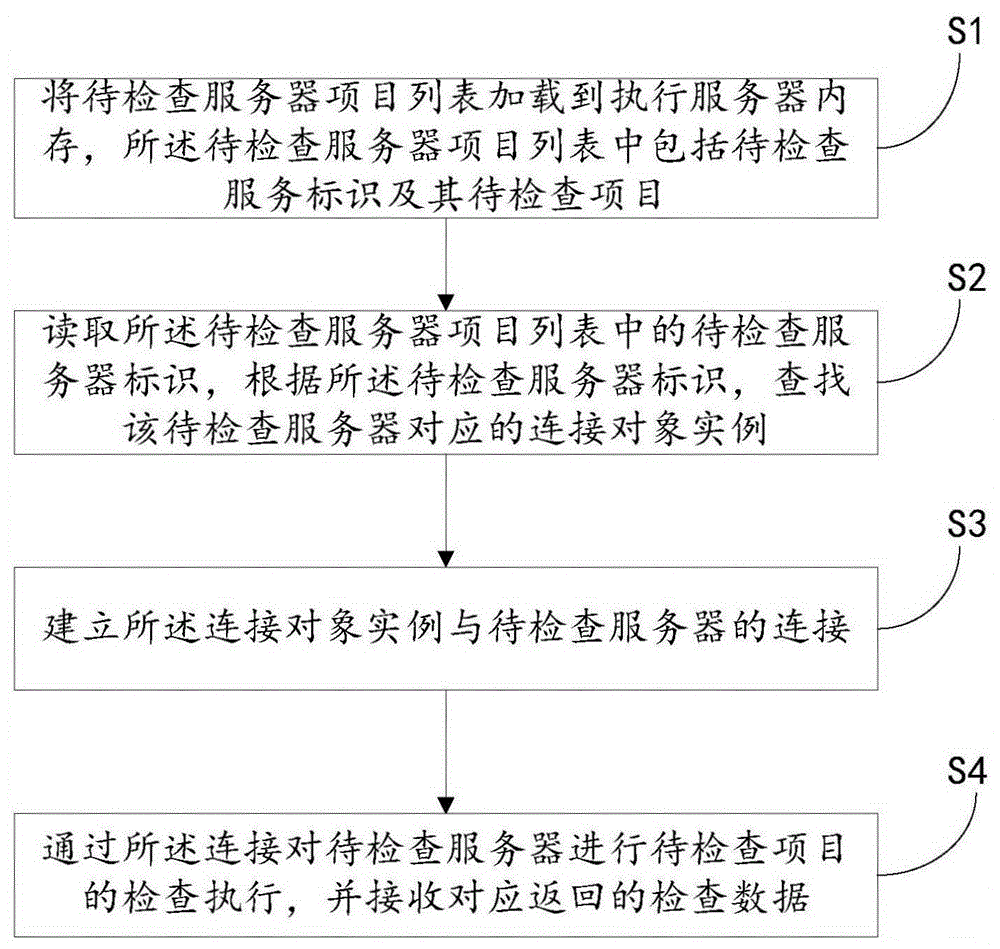

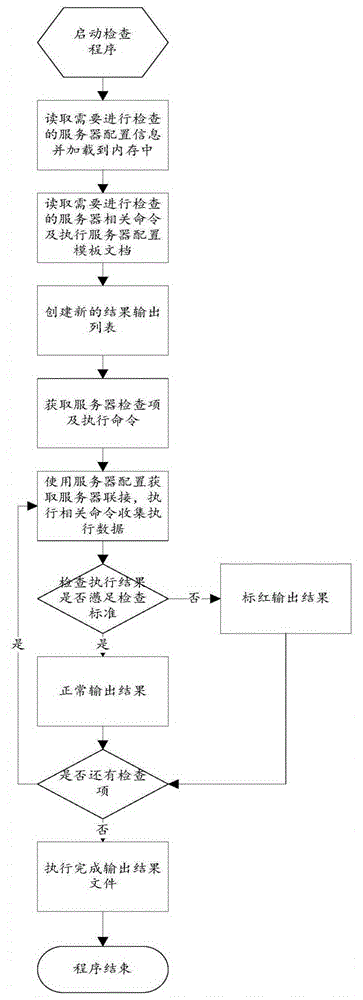

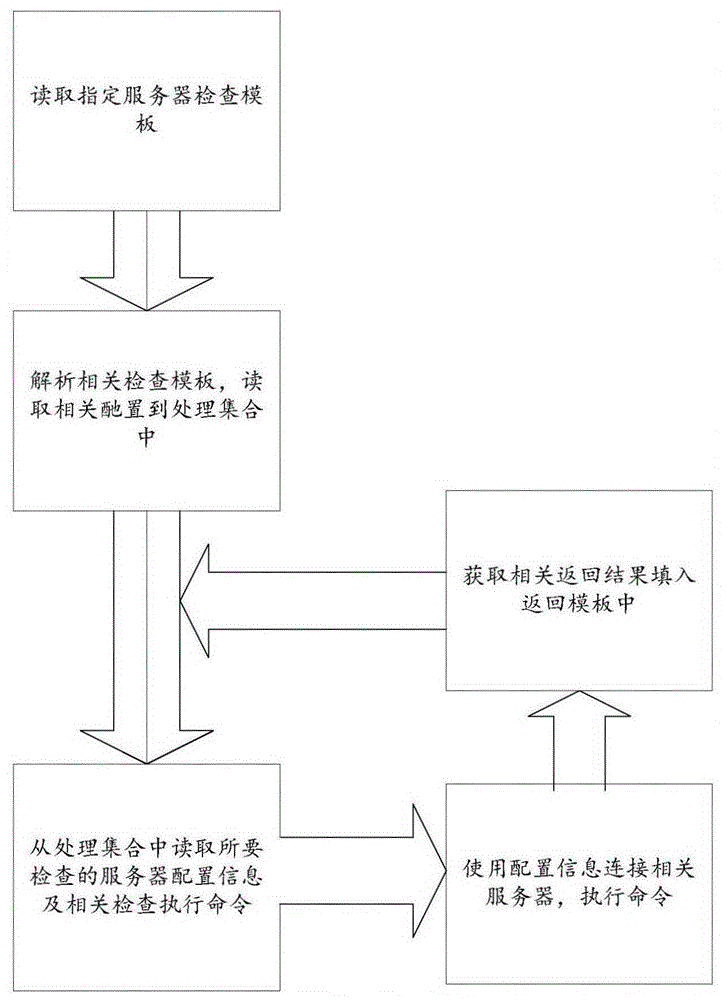

Automatic check and maintenance method and system for server

The present invention discloses an automatic check and maintenance method and system for a server. The method comprises: uploading a to-be-checked server item list to an execution server memory, wherein the to-be-checked server item list comprises a to-be-checked service identifier and to-be-checked items; reading the to-be-checked service identifier in the to-be-checked server item list, and according to the to-be-checked server identifier, searching for a connecting object instance corresponding to a to-be-checked server; establishing a connection between the connecting object instance and the to-be-checked server; and by using the connection, checking and executing to-be-checked items for the to-be-checked server, and receiving check data returned correspondingly. According to the method provided by the present invention, the relevant check items of the to-be-checked server can be checked automatically, so that each check item can be monitored and checked effectively and timely, and the checking precision and efficiency are improved.

Owner:北京思特奇信息技术股份有限公司

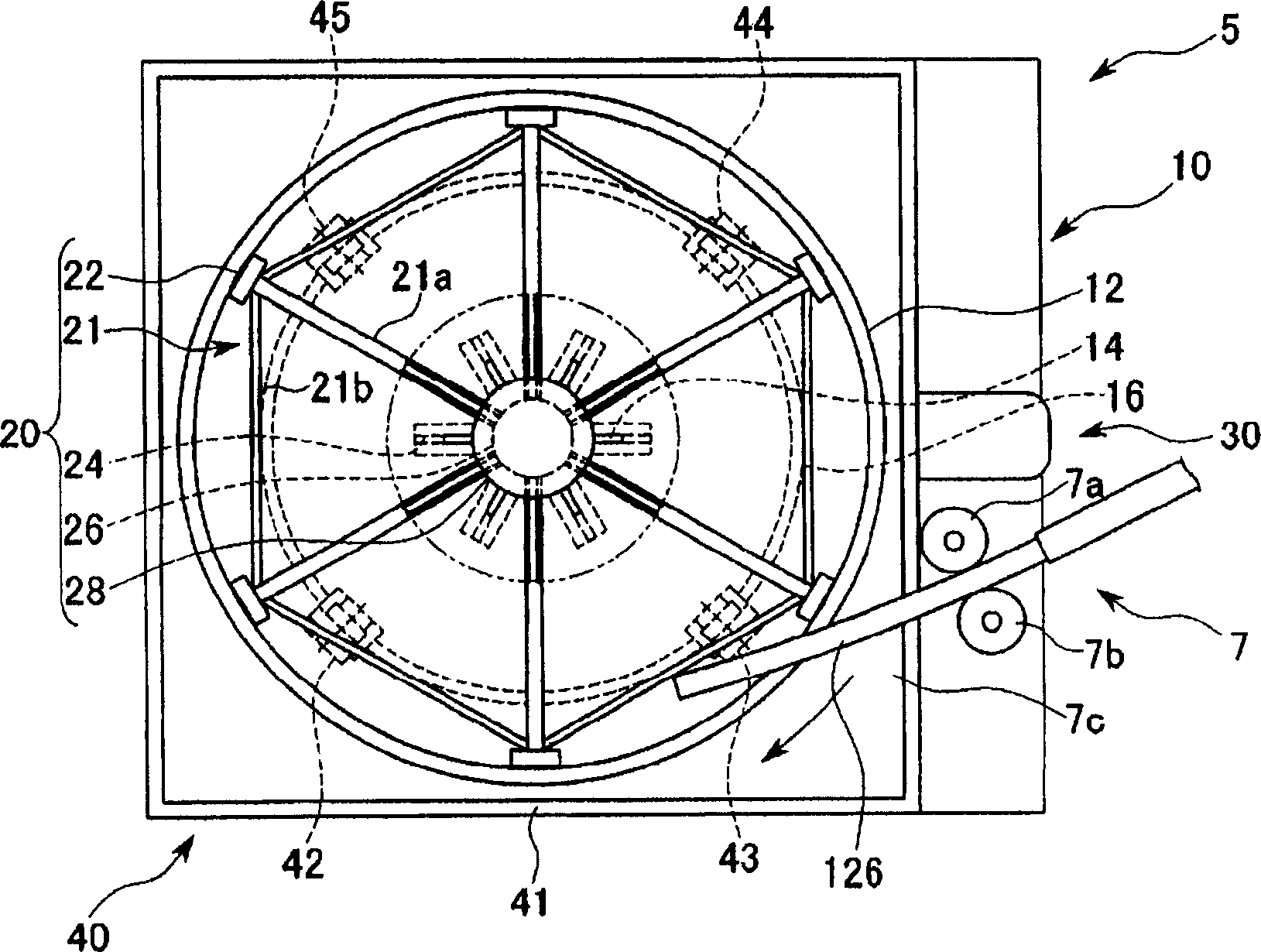

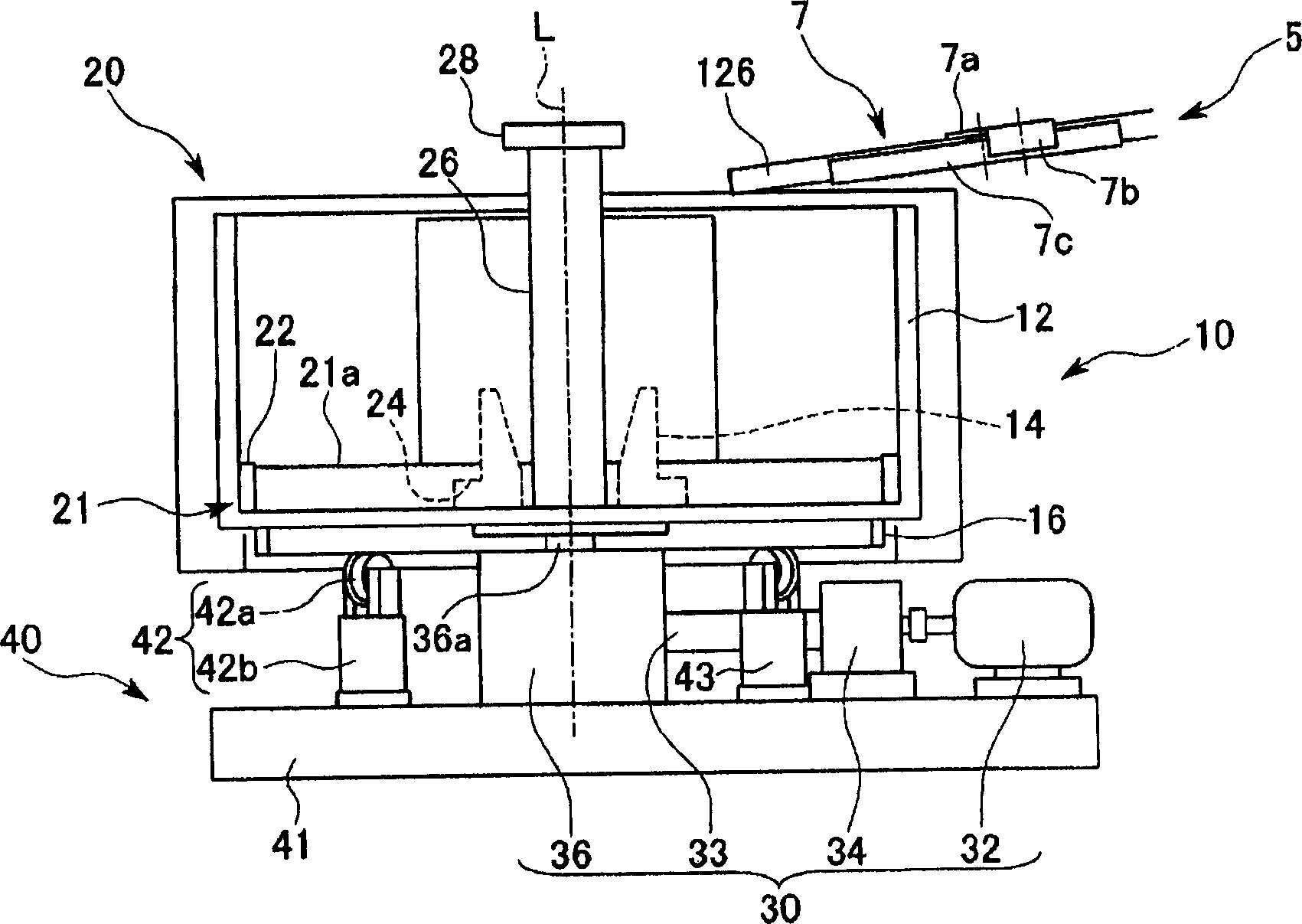

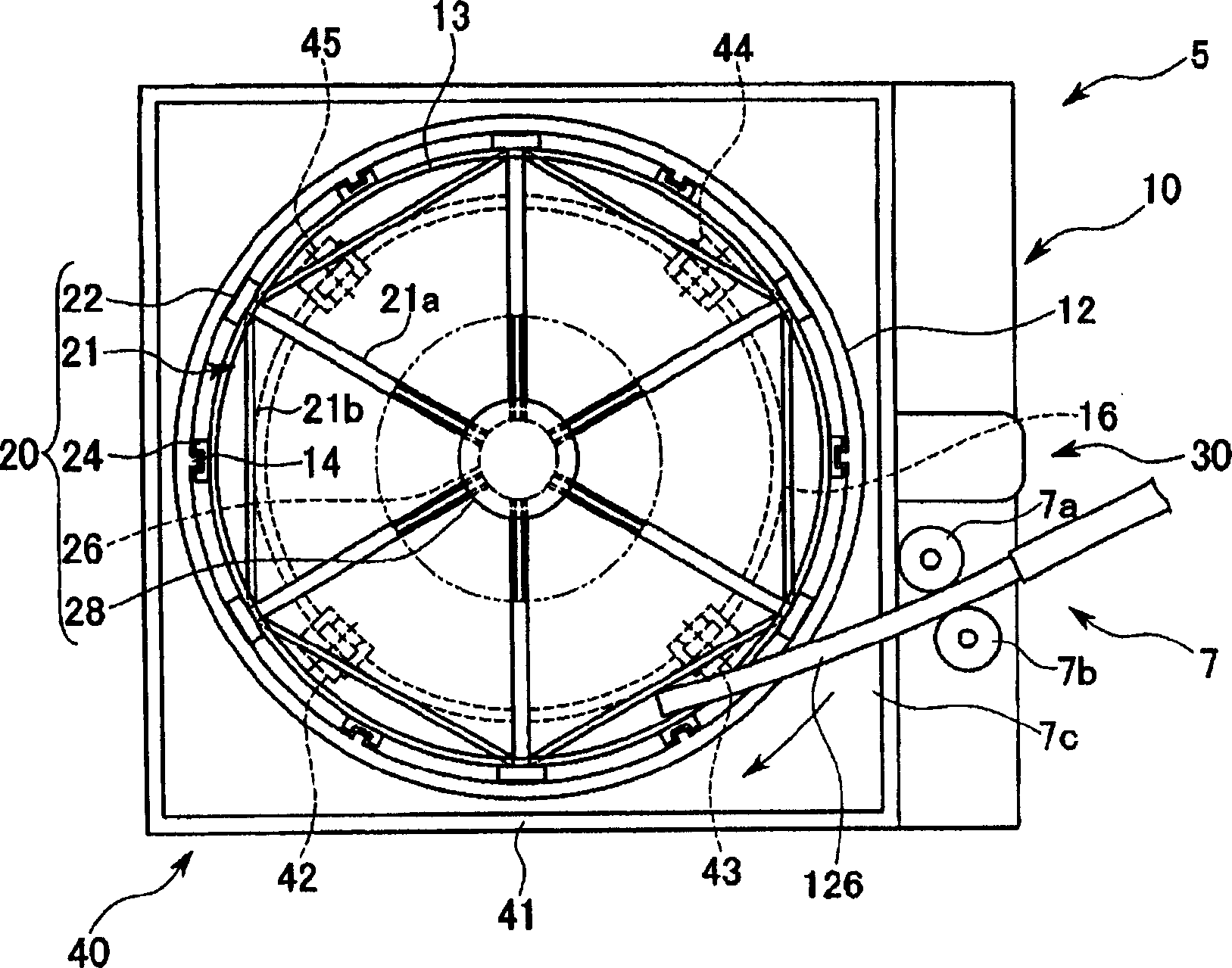

Method for manufacturing copper wire rod and winding device

InactiveCN1833813ANo damageSave spaceData processing applicationsFilament handlingWinding machineCopper wire

The invention relates to a method for producing line copper mother metal of coil, and relative winding machine, which can improve the quality and the efficiency, and coil present line copper mother metal whose diameter is more than 25mm, to improve the operational property. The winding machine continuously winds the line copper mother metal the guided out from the continuous casting machine and compressed extend in the compress extend process. It is characterized in that: it has a cooling reduction groove (10) which can keep the reduction solution that dipping said line copper mother metal; and a winding axle (2) inside said cooling reduction groove (10).

Owner:MITSUBISHI MATERIALS CORP

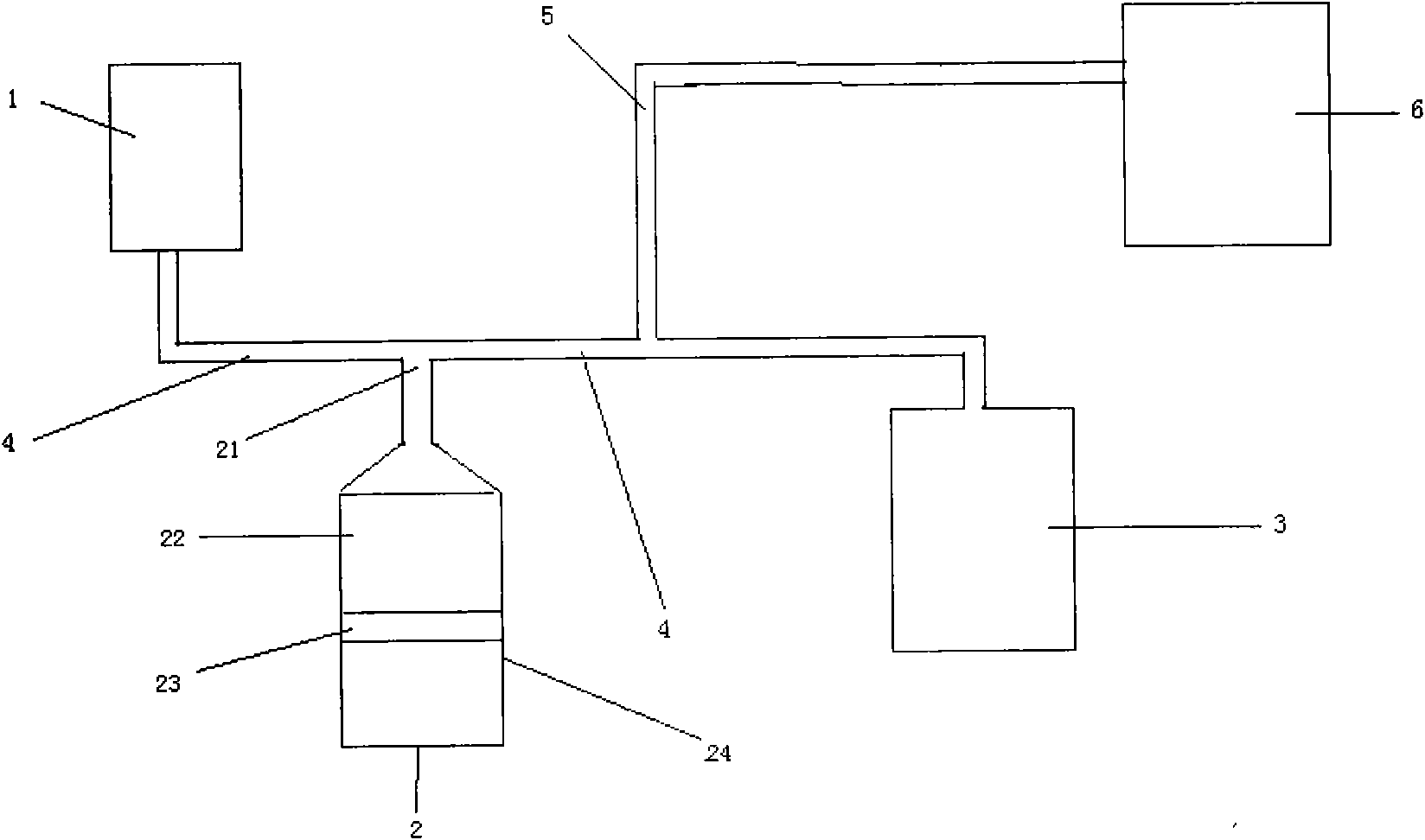

Measuring method for storage capacity of reservoir

InactiveCN102853875AReal-time reflection of dynamic changesReduce errorsVolume measurement apparatus/methodsMachines/enginesReal-time dataPersonal computer

The invention relates to a measuring method for the storage capacity of a reservoir (2), and a measuring system is composed of pressure sensors (3, 8), a laser sensor (4), a sonar sensor (5), an adopting camera (6) and a pc (personal computer) machine (7). The measuring method comprises the steps of utilizing the laser sensor (4) to measure the upper surface area of the reservoir (2), and meanwhile starting the camera (6) to take pictures; utilizing the sonar sensor (5) to measure the depth of water, and comparing the water depth of a target rod with the depth of the water; correcting the measured data according to reservoir establishing data to obtain surface area, water depth and floor space, thereby obtaining the volume of water; and utilizing the pressure sensors (3, 8) to measure the pressure of the reservoir (2) to a reservoir bottom and a reservoir side. The measuring method provided by the invention automatically measures volume, depth and pressure, the manual operation error is reduced, a dynamic variation condition of the storage capacity is reflected, and more real-time data is provided for a reservoir detection system; and meanwhile, the detection operation is simple, convenient and exact, and manpower, financial resources and material resources are saved.

Owner:NANJING DAWU EDUCATION TECH

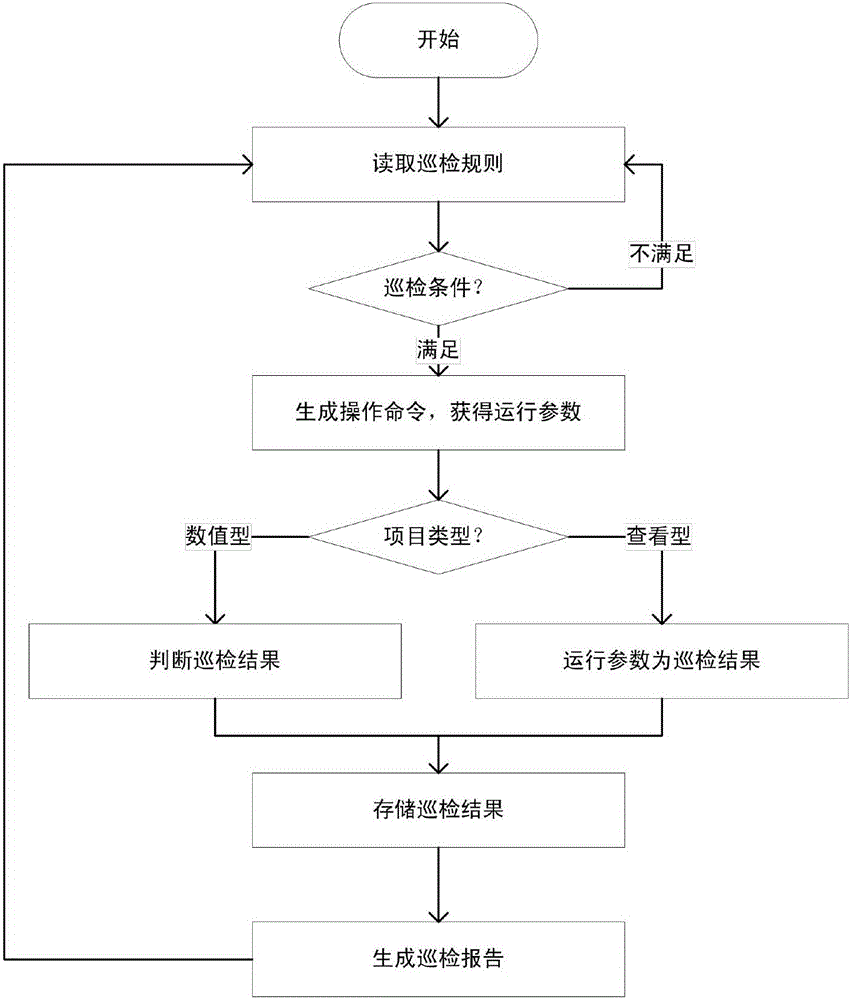

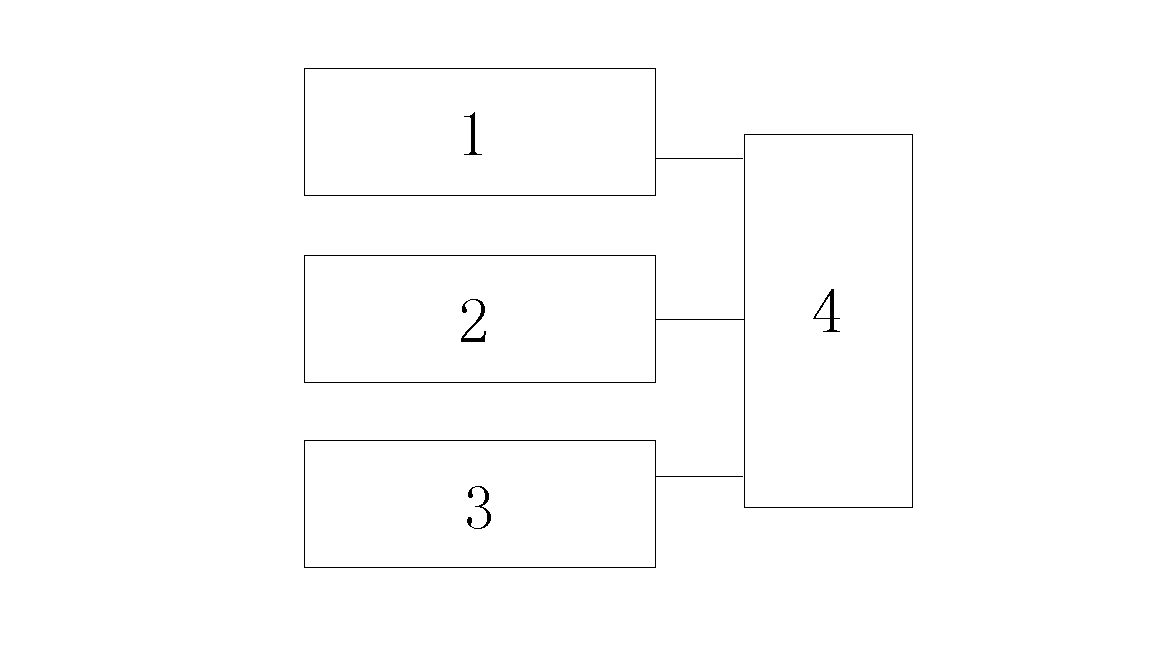

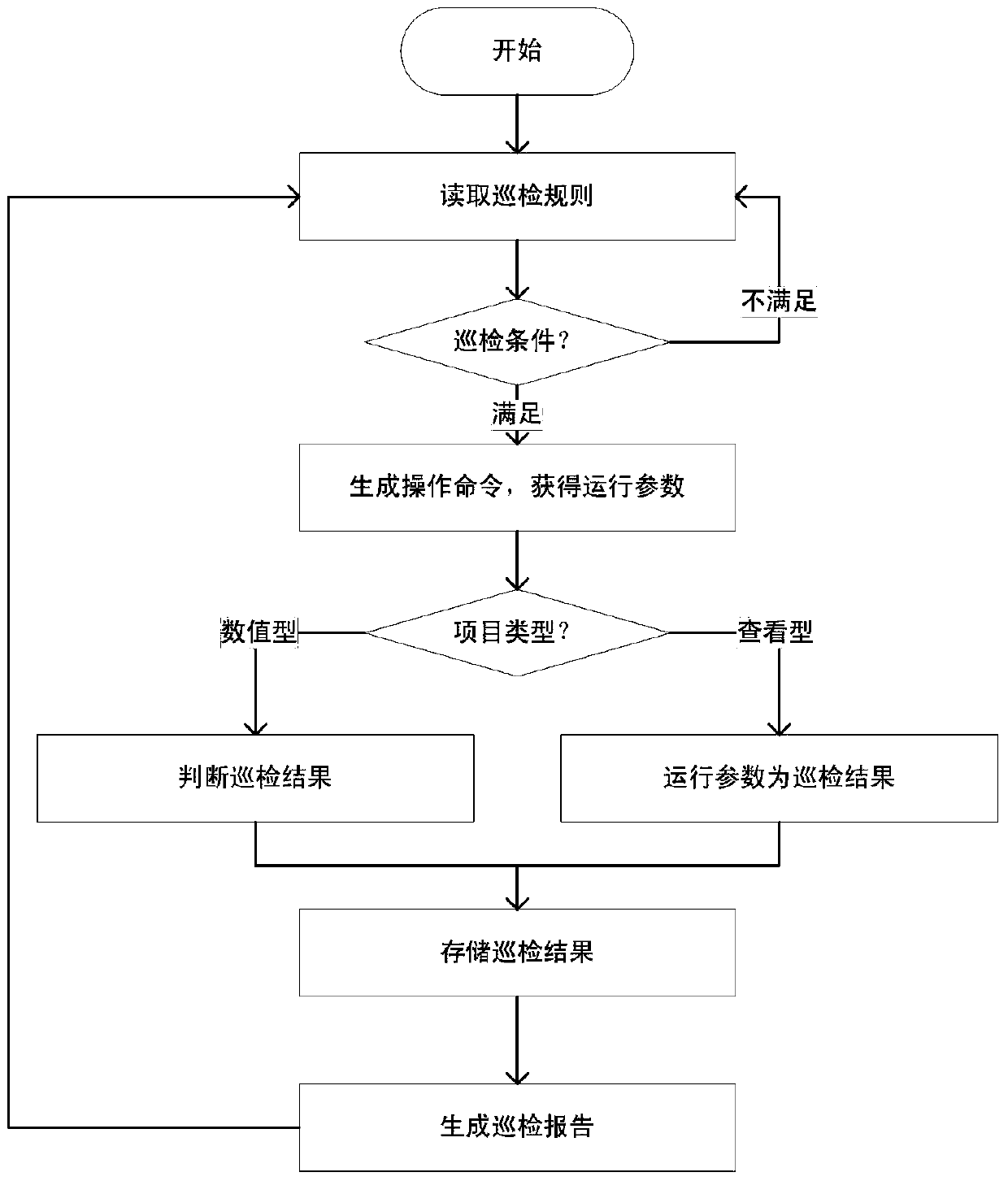

Switch automatic inspection system and inspection method thereof

ActiveCN105072056AImplement automatic connectionSimplify workData switching networksComputer hardwareEngineering

The present invention discloses a switch automatic inspection system and an inspection method thereof. The system comprises a database module, a switch control module and a report generation module. The database module is used for storing an inspection rule, switch configuration information and switch command information. The switch control module is used for connecting a switch and obtaining the operating parameter of the switch and an inspection result. The report generation module reads the inspection result and generates an inspection report based on the inspection rule. According to the inspection system and the inspection method, a terminal, a corresponding switch and a port can be rapidly obtained, thus the working of network operation and maintenance staff is simplified, the working efficiency is improved, and a lot of labor costs are saved.

Owner:STATE GRID CORP OF CHINA +1

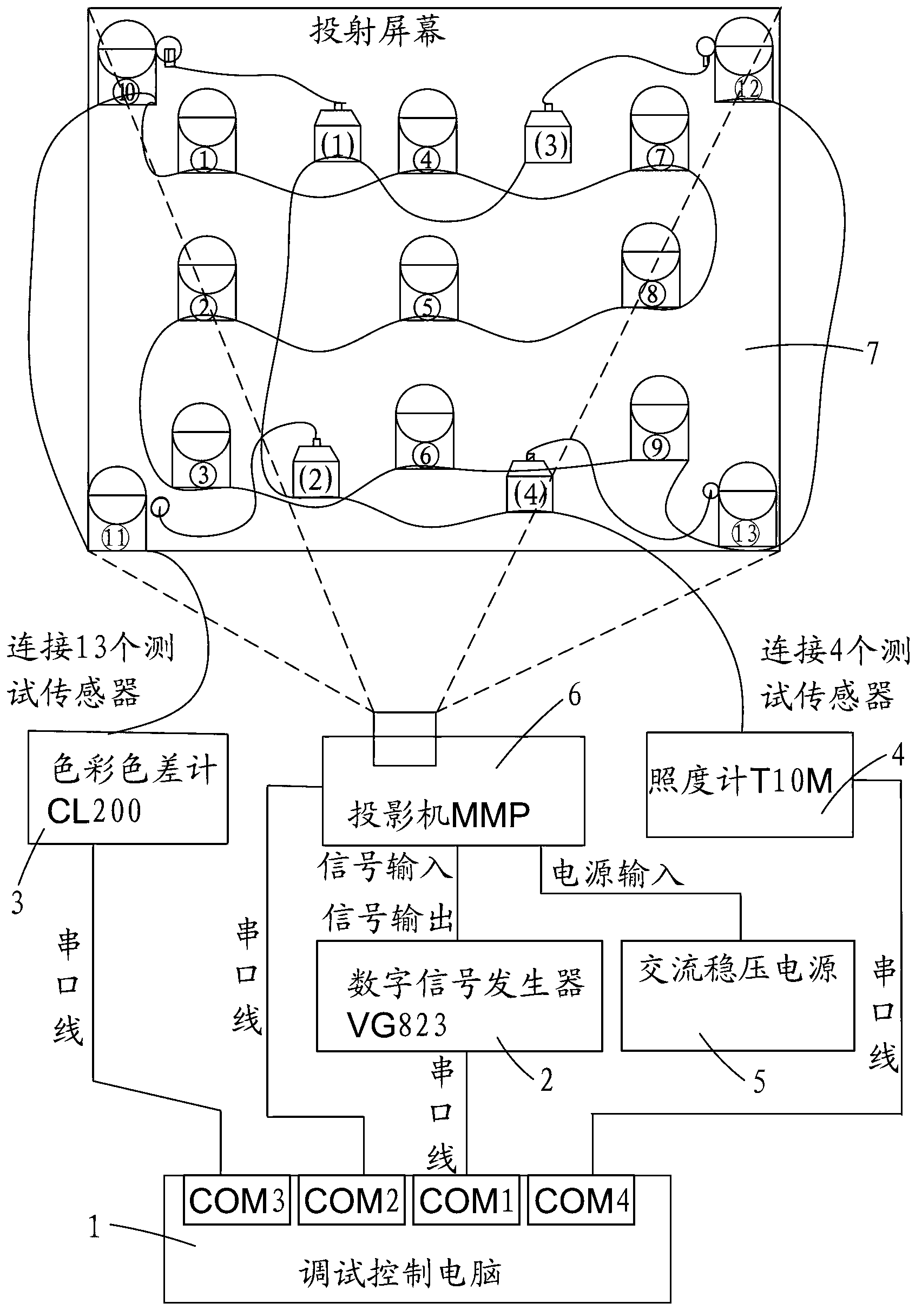

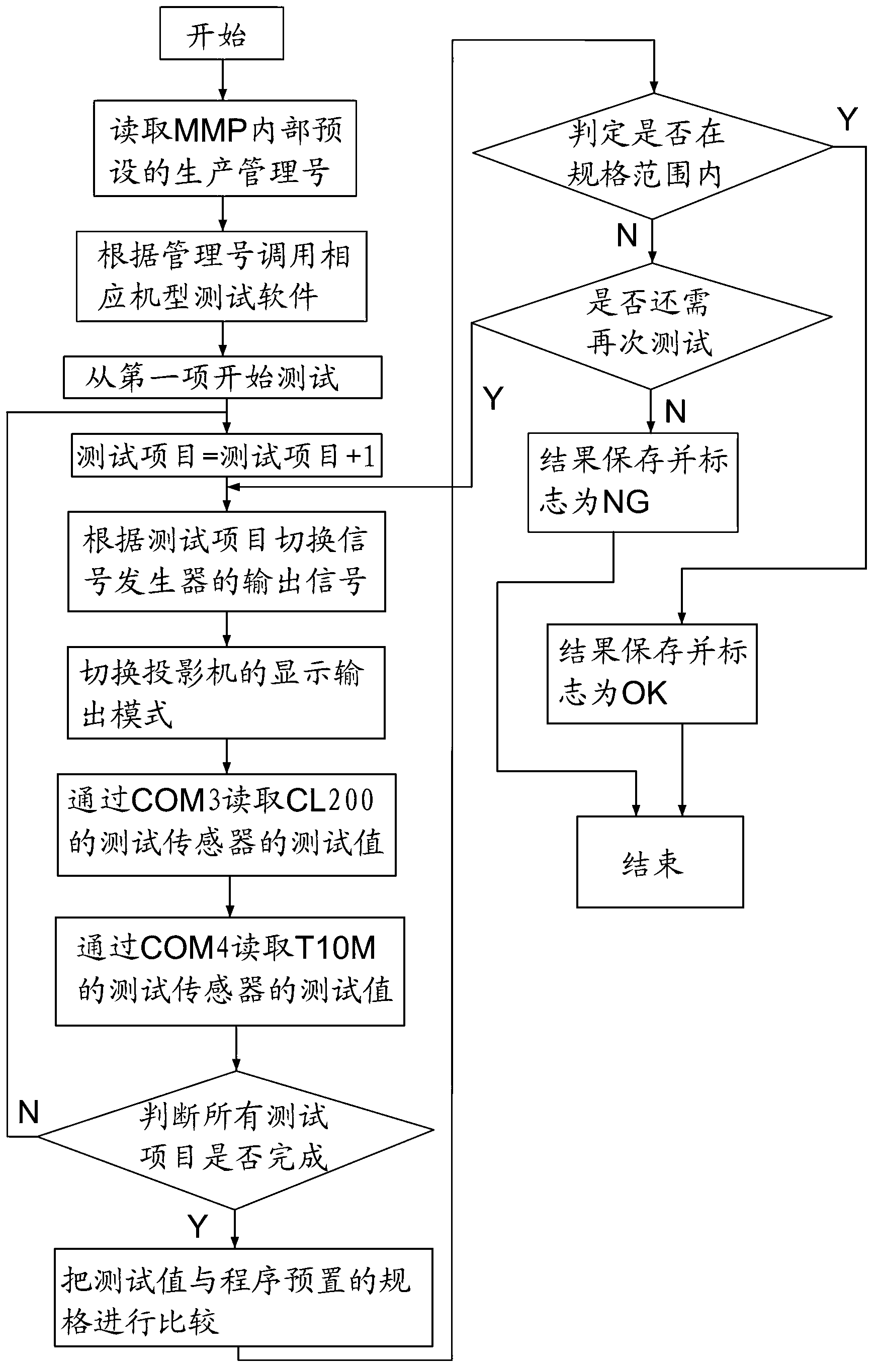

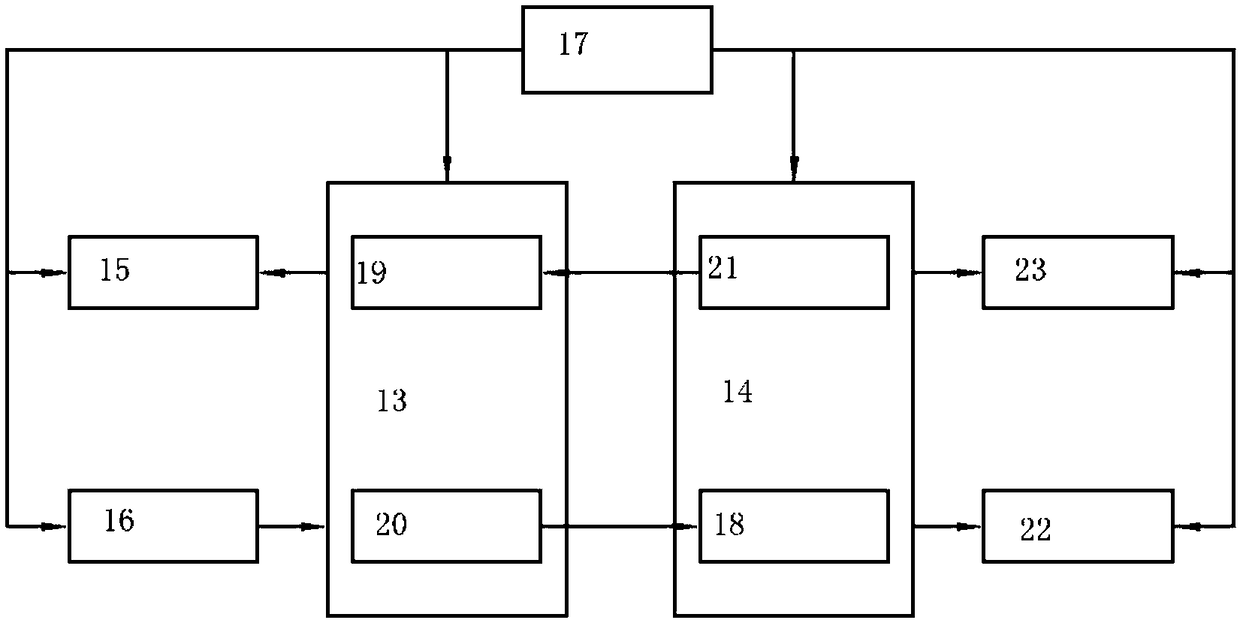

Optical performance detection device of liquid crystal projector

InactiveCN103267630AAvoid false detectionImplement automatic storageTesting optical propertiesLuminance meterProjection screen

The invention discloses an optical performance detection device of a liquid crystal projector. The optical performance detection device of the liquid crystal projector comprises a debugging control computer, a digital signal generator, a color difference meter, a luminance meter, an alternating-current voltage stabilization power source and a projector to be detected. Four control ports of the debugging control computer are connected to the digital signal generator, the projector to be detected, the color difference meter and the luminance meter respectively through serial communication lines. The projector to be detected is connected to the alternating-current voltage stabilization power source. The projector to be detected is further connected with the digital signal generator. Seventeen test sensors are installed on a projection screen of the projector to be detected. The optical performance detection device of the liquid crystal projector is arranged in a test darkroom. According to the optical performance detection device of the liquid crystal projector, the projector is automatically detected through an optical automatic detection PC, detection work is simplified, detection time is reduced, the number of detection inspectors is reduced, detection efficiency is improved, detection missing and false detection by the detection inspectors are avoided, and automatic storage of detected data can be further achieved.

Owner:麦克赛尔数字映像(中国)有限公司

Method for treating ingredients of biological fluid

InactiveCN101620218ASimplify inspection workAvoid instabilityPreparing sample for investigationBiological testingCord blood stem cellAdditive ingredient

The invention provides a method for treating ingredients of biological fluid, which comprises the following basic steps: the biological fluid in a sample vessel which holds the biological fluid to be separated is transferred to a centrifugal separation device; after the biological fluid is settled in a centrifugal chamber device, the centrifugal device rotates around a shaft to separate the ingredients of the biological fluid; separated ingredients are extruded when the centrifugal device rotates, and the separated ingredients are distributed in a vessel holding separated samples through a fluid passage device; and when a target ingredient occurs, a branch is started to collect trace samples for detecting. The operation process is completed in integrated equipment. The method is applicable to the separation and the detection of ingredients of the biological fluid, including peripheral blood, bone marrow, cell culture fluid, placenta and cord blood.

Owner:上海奇康生物科技开发有限公司

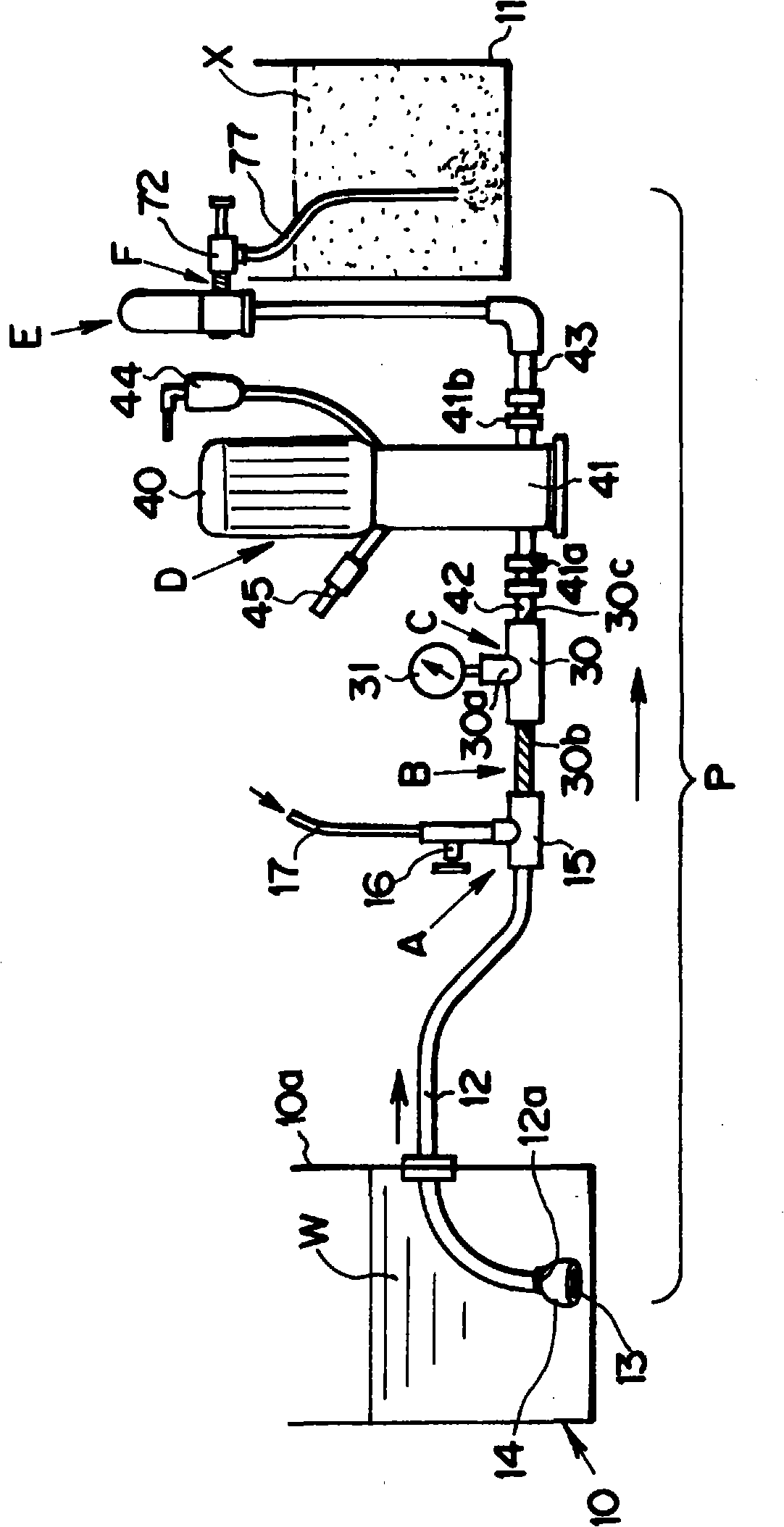

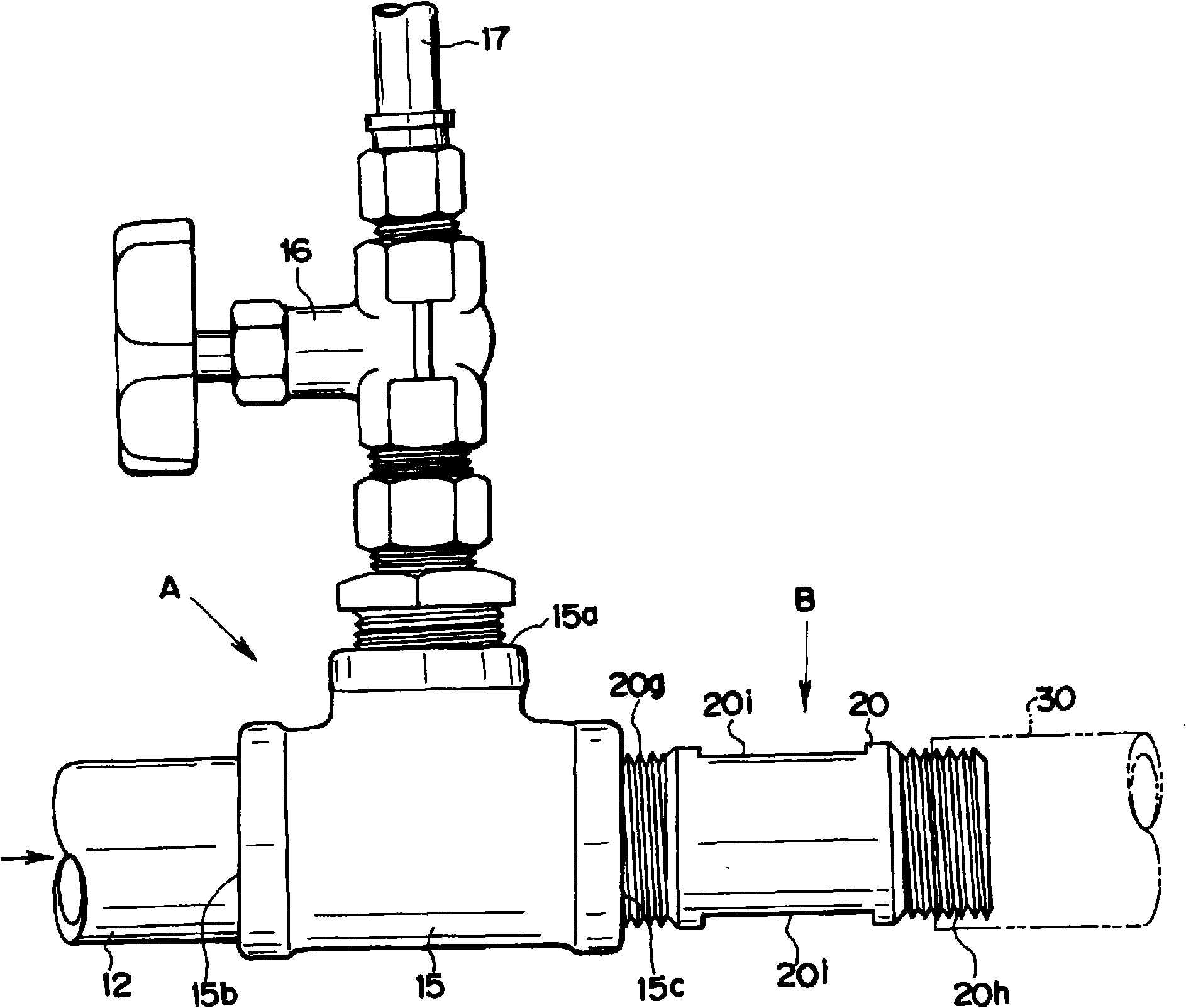

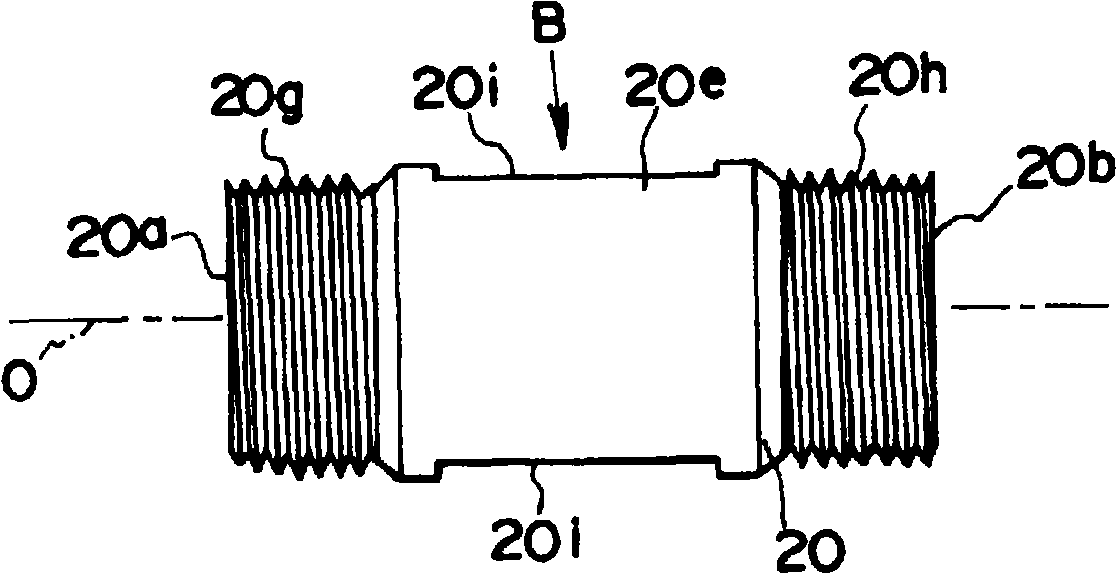

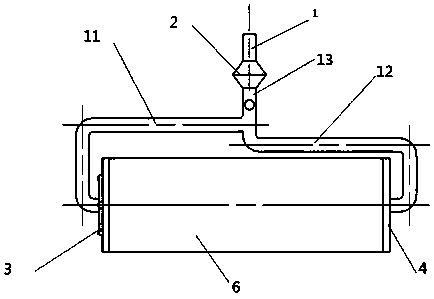

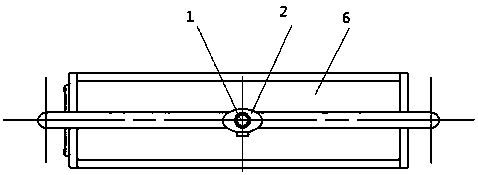

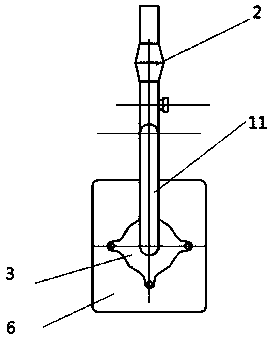

Device for creating liquid with fine air bubbles, and device for fining air bubbles, used for the same

InactiveCN101267876AWork lessEasy to checkFlow mixersTransportation and packagingEngineeringGas blending

A device for creating a liquid with fine air bubbles, capable of efficiently creating the liquid containing sufficiently fine air bubbles and being simple and low in cost. A device for fining air bubbles, used for the apparatus, is also provided. A pressure pump (D) for sucking liquid from a liquid supply source (10) and sending the sucked liquid by pressure is provided in liquid supply pipeline (P). An air bubble liquid creater (A) for creating air bubble liquid by mixing gas into liquid by suction pressure of the pressure pump (D) is placed in the liquid supply pipeline (P), on the upstream side in a liquid supply direction of the pressure pump (D).; A first air bubble fining device (B) for fining the air bubbles contained in the air bubble liquid created by the air bubble liquid creater (A) is placed in the liquid supply pipeline (P) on the downstream side in the liquid supply direction of the air bubble liquid creator (A). A second air bubble fining device (F) for further fining the air bubbles fined by the first air bubble fining device (B) is placed in the liquid supply pipeline, on the downstream side in the first air bubble fining device (B).

Owner:KIKUCHI ECO EARTH

Experiment method and device for ablation and abrasion resistance of rapid-fire weapon barrels

ActiveCN108562507AImprove accuracySimplify inspection workMaterial thermal analysisInvestigating abrasion/wear resistanceEngineeringHigh pressure

The invention provides an experiment method and device for ablation and abrasion resistance of rapid-fire weapon barrels. The method comprises the steps that 1) an experiment device is prepared, wherein the device comprises a pipe, an explosion shock explosive box or an explosive feeding port, a heating device and a high-pressure gas device; 2) the rapid-fire weapon barrels are connected to the two ends of the pipe respectively, and inner cavities are communicated with an inner cavity of the pipe separately to form a sealed gas channel; the rapid-fire weapon barrels and the heating device arecooperatively installed; 3) explosion shock explosive is heated or ignited, and a burning compound is obtained through burning; 4) high-pressure gas and the burning compound enter the inner cavities of the rapid-fire weapon barrels; 5) the rapid-fire weapon barrels are heated and cooled to obtain the rapid-fire weapon barrels. According to the method, from three aspects of the temperature, atmosphere and abrasion, the real environment where bullets or cannonballs penetrate through the barrels is simulated, the accuracy of a detection result is improved, the detection work is simplified, and the working efficiency is high; the experiment cost is lowered, the labor amount is greatly lowered, and the labor cost is reduced.

Owner:CHONGQING UNIV OF TECH

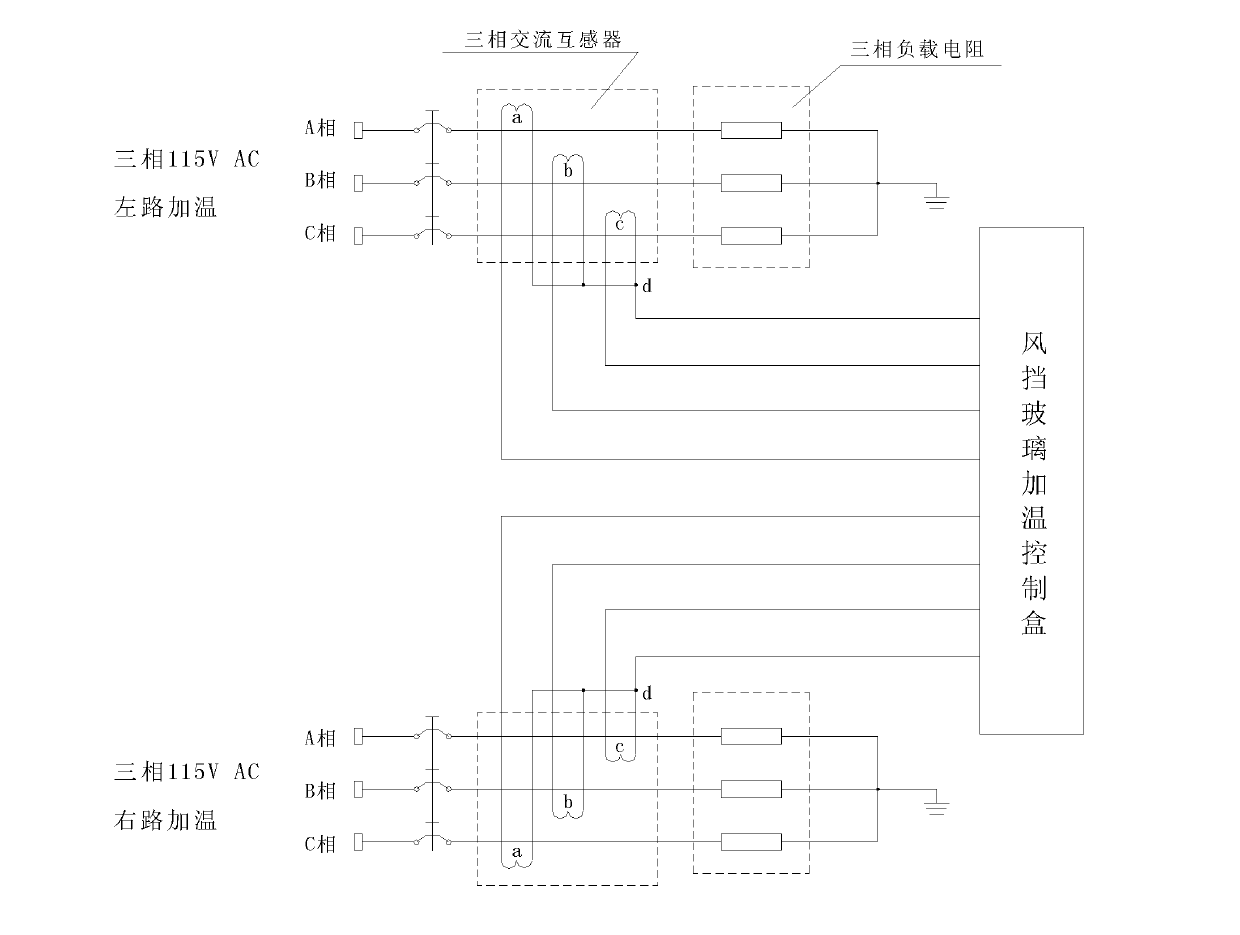

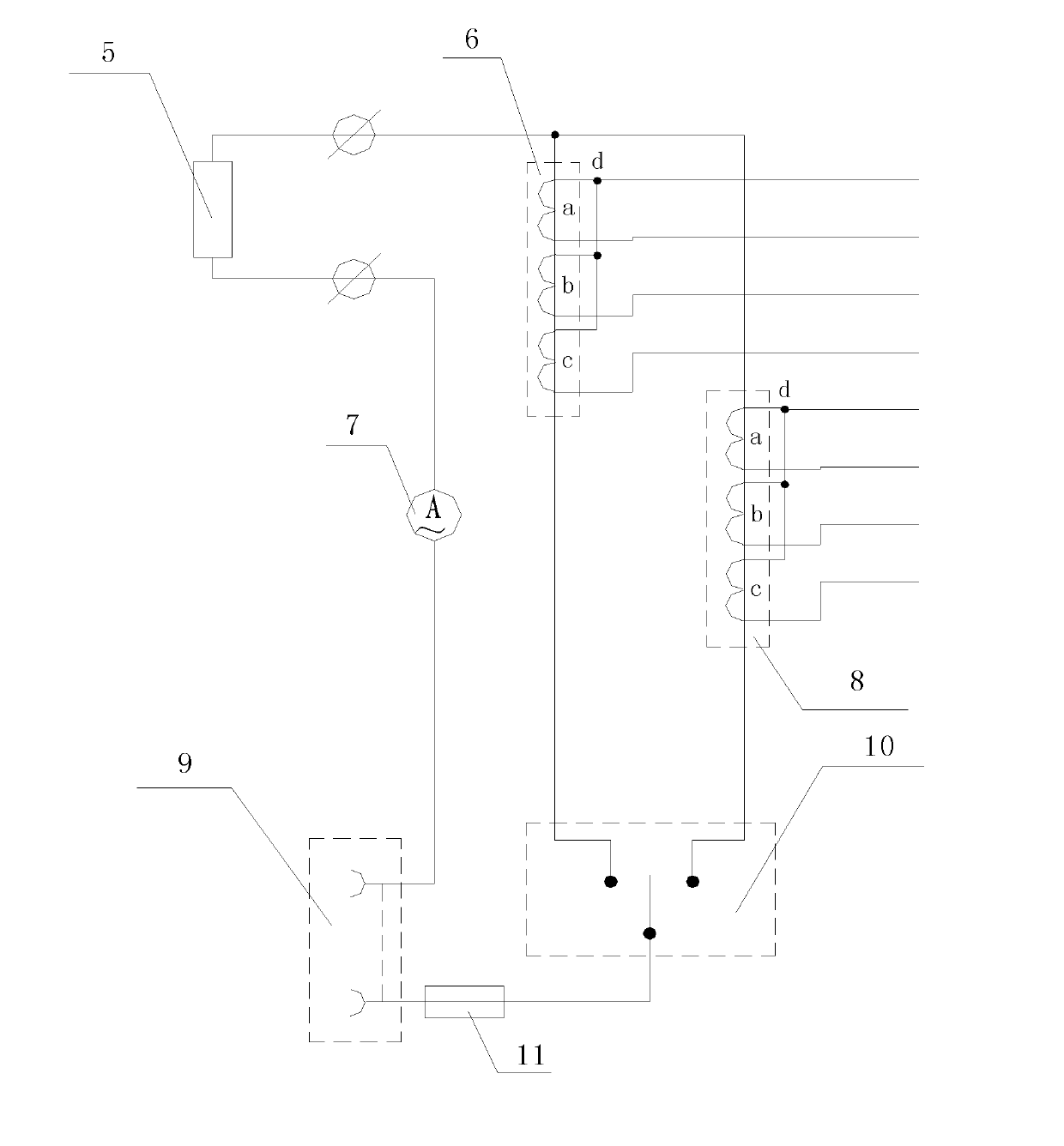

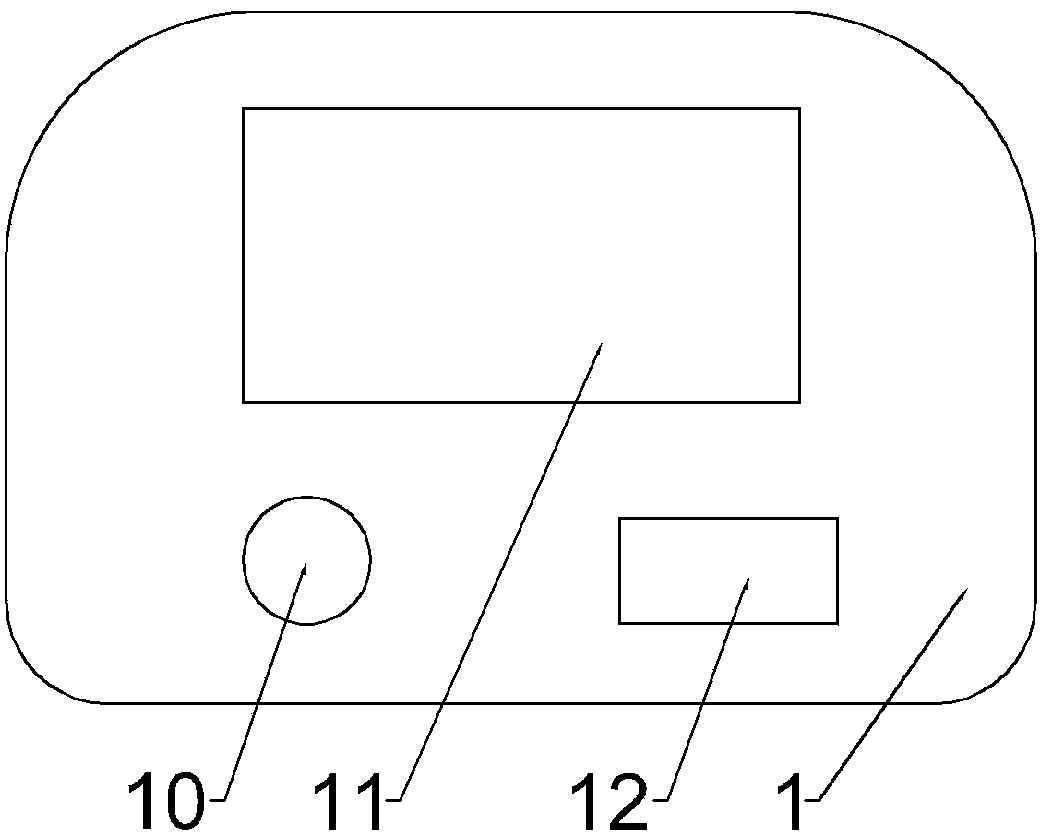

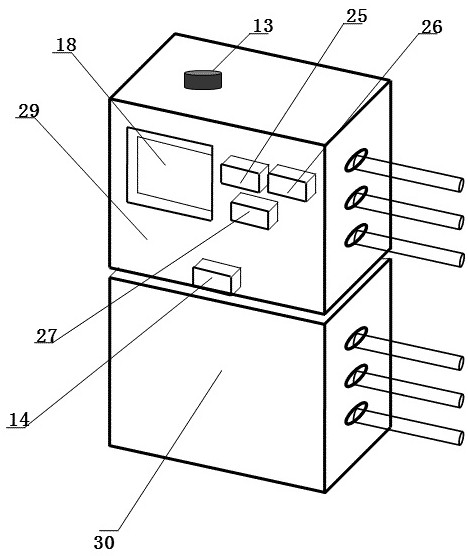

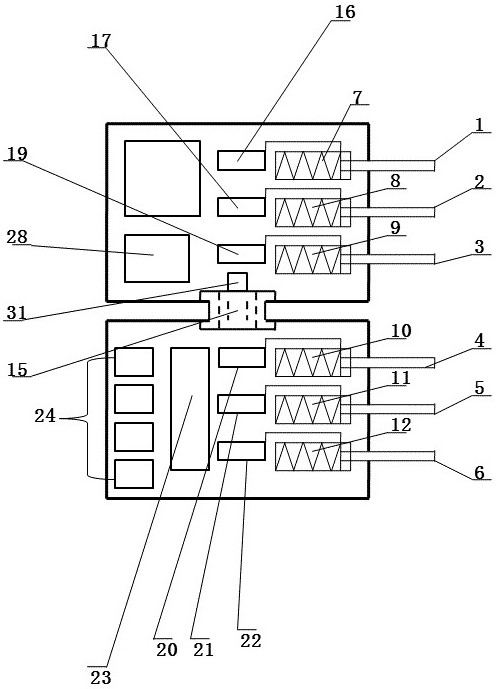

Heating control box detection device of airplane windshield

ActiveCN103309343AReduce manufacturing costSimplify inspection workElectric testing/monitoringElectrical resistance and conductanceComputer module

The invention belongs to the testing technology and relates to a heating control box detection device of an airplane windshield. The heating control box detection device of the airplane windshield comprises an AC signal module, a DC display module, a resistance conversion module and a connection output module. The AC signal module for providing a three phase current signal to a heating control box, the DC display module for providing a DC signal to the heating control box, and the resistance conversion module for providing a resistance signal to the heating control box are mutually independent, and are respectively connected with the connection output module which is used for providing an output signal to the heating control box. The AC signal module comprises a left three phase AC mutual inductor, a right three phase AC mutual inductor, a change over switch and an externally connected load. According to the invention, the one phase 115V is used to replace the three phase 115V as a power supply, and one slide bar resistor is used to replace three load resistors. The detection circuit is effectively simplified; the production cost of the detection device is reduced; and the detection work is easier to carry out.

Owner:SHAANXI AIRCRAFT CORPORATION

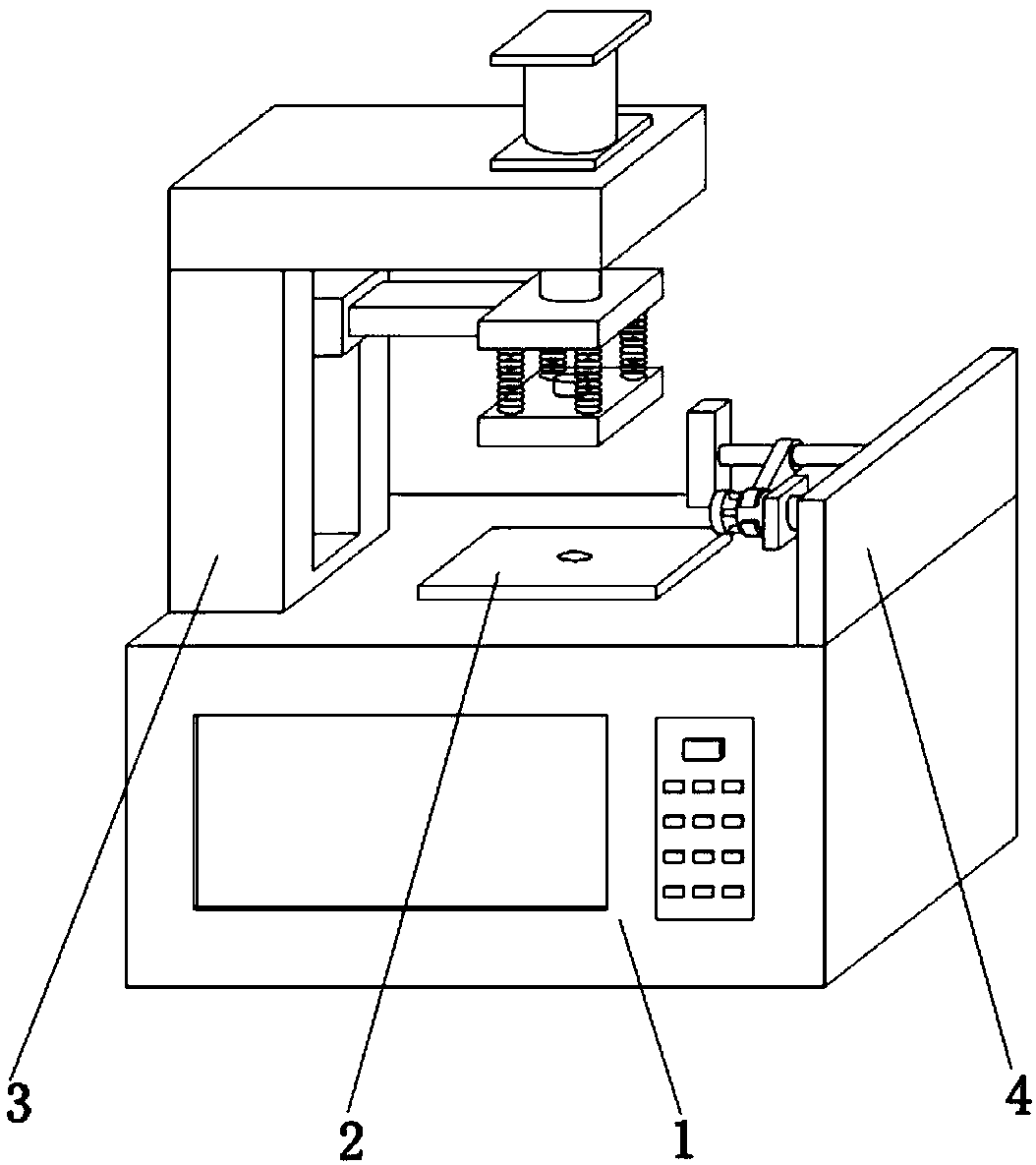

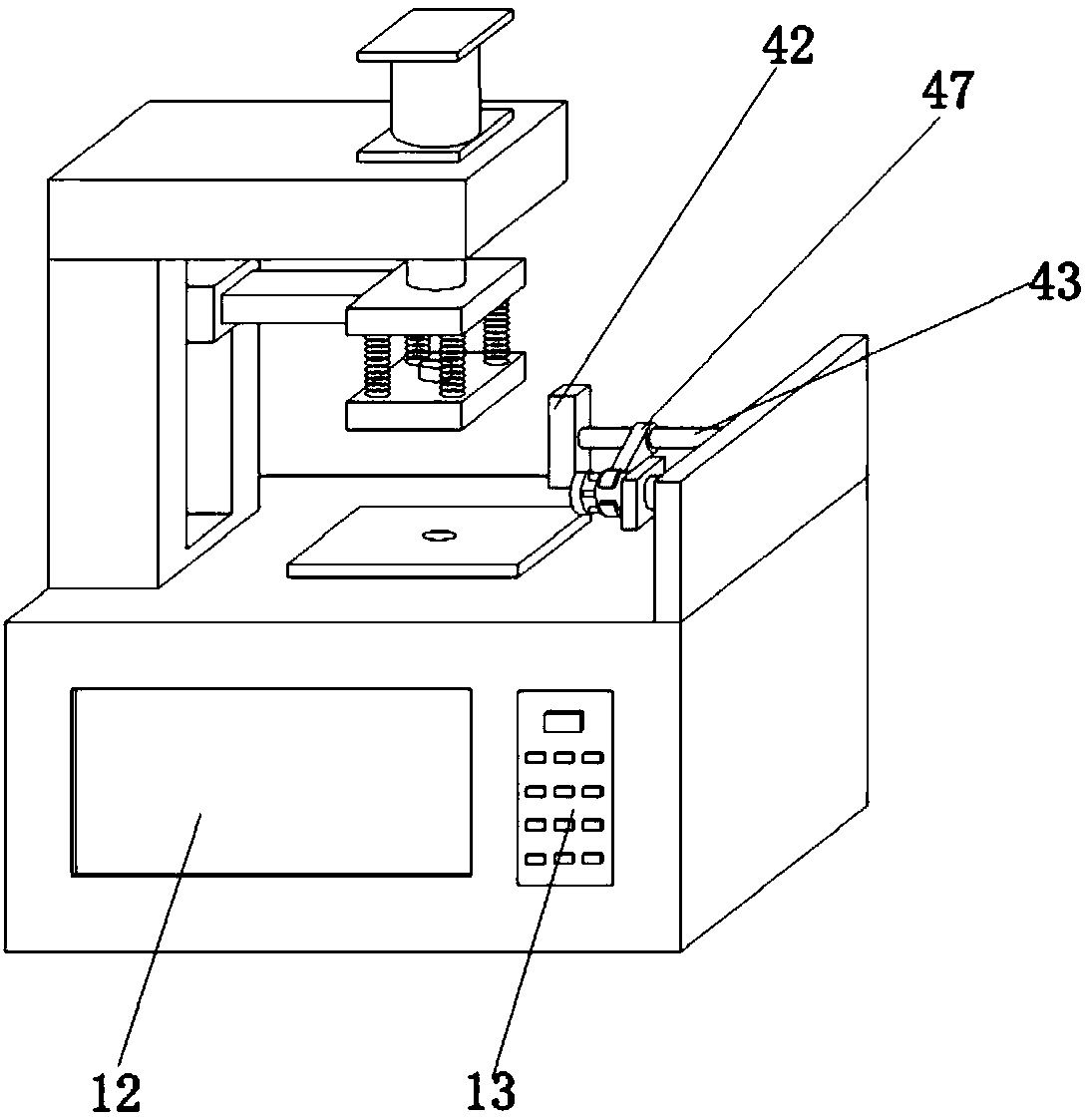

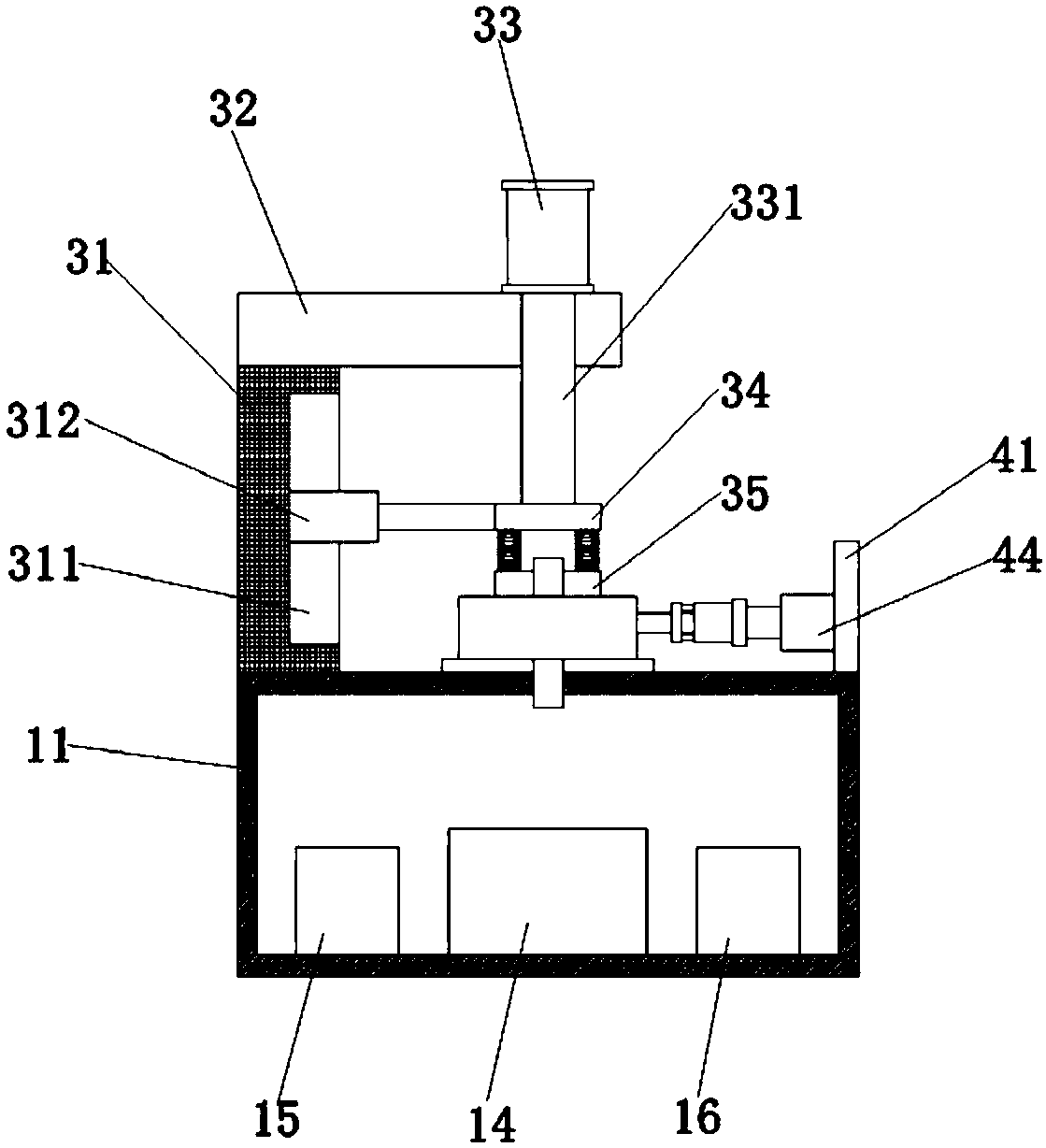

Inductance detecting device after film cracking of ferrites coating

InactiveCN109444557AImprove securityImprove stabilityResistance/reactance/impedenceComputer moduleEngineering

The invention provides an inductance detecting device after film cracking of a ferrite coating, which comprises a device body. The device body comprises a control box, a carrier base, a detecting mechanism and a marking mechanism, wherein the carrier base is centered on the top of the control box. A ferrite body is placed above the carrier base, and the detecting mechanism is located on one side of the top of the control box. The marking mechanism is located on the other side of the top of the control box; a second detecting head, the ferrite body, a first detecting head and an inductance measuring module form a loop when an lower pressure plate is pressed on the ferrite body, and the inductance measuring module automatically detects and determines the inductance quantity of the ferrite body, and marks the side of the ferrite body which the inductance quantity is not qualified. The automatic and intelligent degree of the device is high, the artificial labor intensity is reduced, the detection efficiency is high, and the production efficiency is improved.

Owner:湖州华龙智能科技有限公司

Equipment used for observing bridge underwater structure object

PendingCN108103964AInspection is simpleInspection work is simpleClosed circuit television systemsBridge erection/assemblyRemote controlControl system

The invention belongs to the technical field of underwater observation, and particularly relates to equipment used for observing a bridge underwater structure object. The equipment is characterized bycomprising an observing carrier, a control system arranged on the observing carrier, an information acquisition system and a protection cover, the observing carrier comprises a remote control ship model, an anti-impact plate, an aquatic plant prevention screen arranged at the bottom of the rear end of the remote control ship model, a transverse bracket which is arranged on the remote control shipmodel, a platform plate, a sonar bracket arranged on the platform plate, a telescopic rod which is arranged at one end of the transverse bracket, a top fixed pulley and a rotary fixed pulley which are arranged on a first-level rod of the telescopic rod and a hoisting frame which is arranged at the top outside the telescopic rod. Inspection check work of the bridge underwater structure part is perfected, so that the check is simple and operable, based on practice of daily check work of all water-passing and water ponding bridge lower structures, and a sonar detector and an underwater camera are integrated with a remote control bearing ship model and a telescopic frame and cooperated with a corresponding image recognition system for recognition and detection.

Owner:UNIV OF SCI & TECH LIAONING

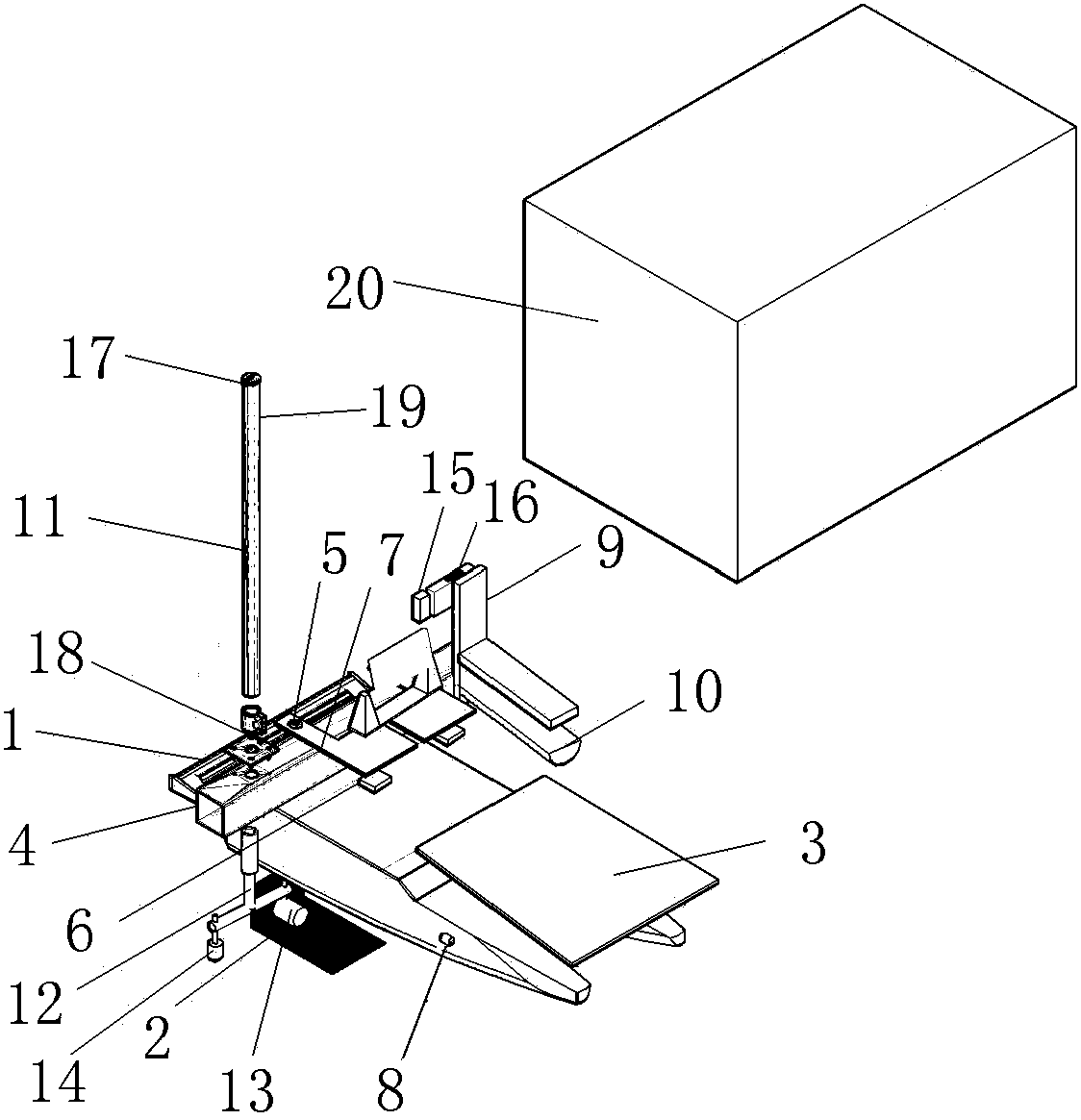

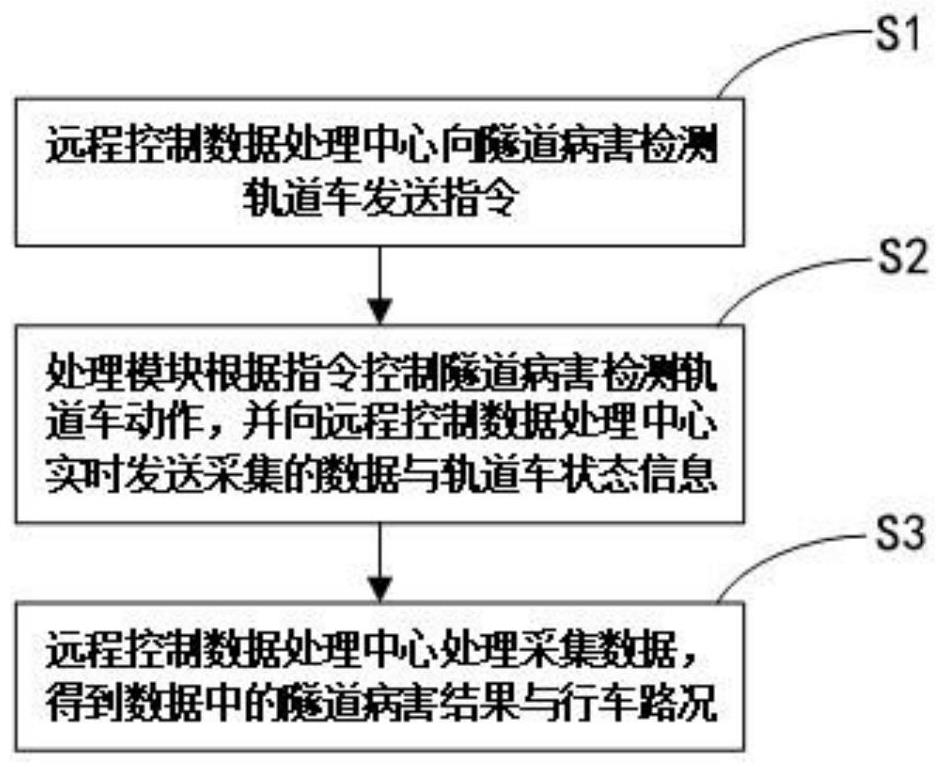

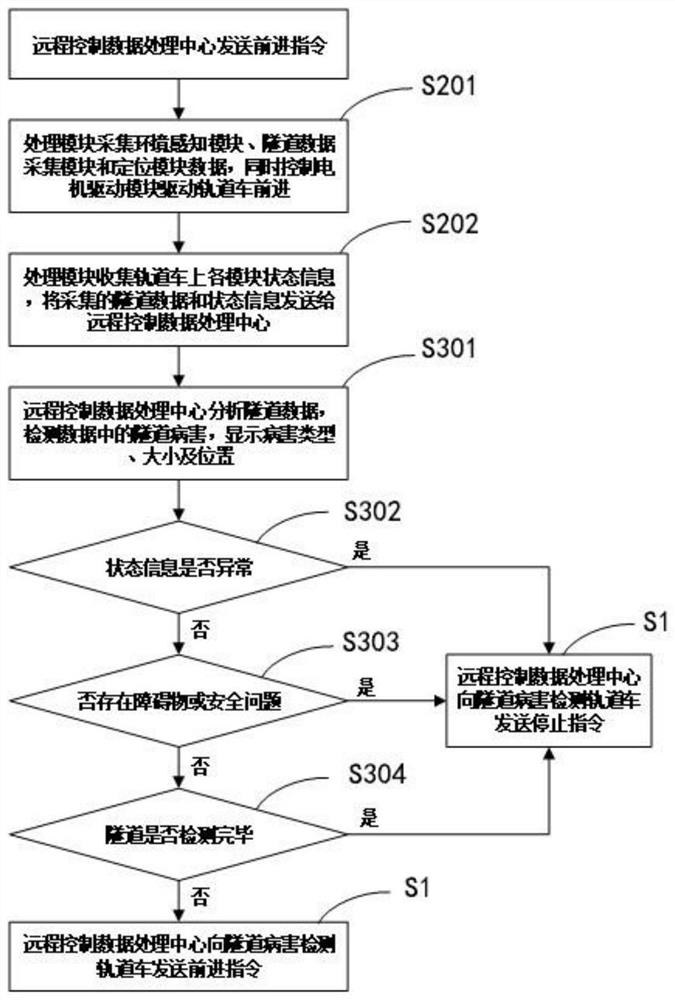

Detection method for remotely controlling tunnel disease detection rail car

PendingCN114063087AReduce staffingEnsure personnel safetyNavigation by speed/acceleration measurementsSatellite radio beaconingReal-time computingData processing

The invention discloses a detection method for remotely controlling a tunnel disease detection rail car. The detection method comprises the following steps that: S1, a remote control data processing center sends an advancing or stopping instruction to the tunnel disease detection rail car; S2, a processing module controls the tunnel disease detection rail car to act according to the received instruction, and sends collected data and the state information of the tunnel disease detection rail car to the remote control data processing center in real time; and S3, the remote control data processing center obtains a tunnel disease result and a driving road condition in the data by processing the collected data, and sends an advancing or stopping instruction to the tunnel disease detection rail car according to the driving road condition and the rail car state information. According to the method of the invention, control and detection of a plurality of tunnel detection cars are realized through the remote control data processing center, personnel are prevented from going to a detection site to carry out car following detection, personnel investment is greatly reduced, and the safety of the personnel is guaranteed.

Owner:CENT SOUTH UNIV

A tunnel detection robot and detection method

ActiveCN105082180BImprove obstacle performanceImprove environmental adaptabilityMeasurement devicesManipulatorEngineeringWorkstation

The invention discloses a tunnel detection robot and a detection method. A support mechanism is provided on a mobile platform of a tunnel detection robot, a movement mechanism is provided on the support mechanism, a slewing mechanism is provided on the movement mechanism, and a base is provided on the slewing mechanism. seat, the base is provided with a driving arm, the base is provided with a rotating mechanical arm, and the rotating mechanical arm is provided with a jacking mechanism; a detection method for a tunnel detection robot, comprising the following steps: (a) establishing a tunnel information workstation; b) Measuring tunnel entrance data; (c) Hoisting tunnel inspection robot; (d) Initial position positioning of tunnel inspection robot; (e) Information acquisition during tunnel inspection; (f) Obstacle removal during tunnel inspection; (g) Tunnel inspection Power management; (h) Tunnel information collection and analysis. The tunnel detection robot of the present invention has strong obstacle-surmounting ability and environmental adaptability, can obtain information data in the whole tunnel through one detection, and the detection is fast, simple and has high precision.

Owner:HANGZHOU HUANENG SAFETY ENG POLYTRON TECH CO LTD

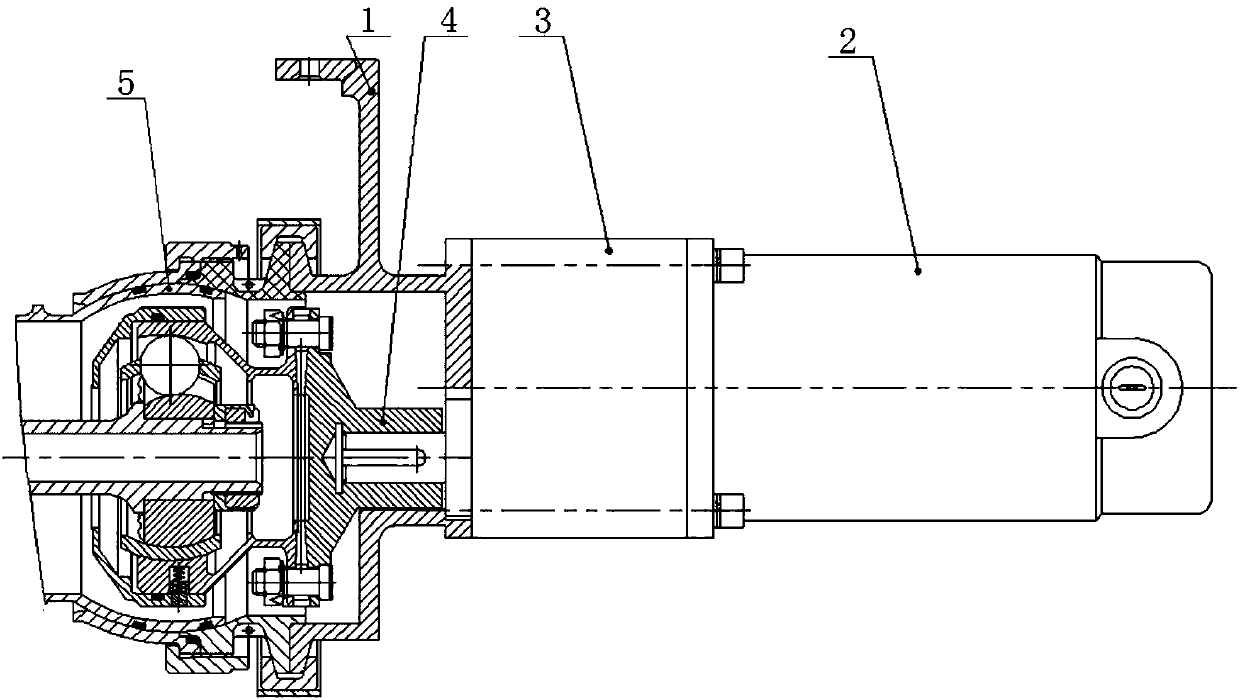

Apparatus for driving aero-engine rotate

PendingCN107941519AGood circuit efficiencyGood observation field of viewEngine testingHinge angleEngineering

The invention relates to an apparatus for driving an aero-engine to rotate. The apparatus is characterized by comprising a support, a motor, a reducer, and a connecting shaft. The output end of the motor is connected with the input end of the reducer. The output end of the reducer is fixedly connected with one end of the connecting shaft. The other end of the connecting shaft is provided with a meshing tooth surface matching the meshing tooth surface of the articulated shaft of the aero-engine. The motor and the reducer are fixedly connected to the support. The support is fixedly connected tothe fan front casing of the aero-engine. The apparatus can rotate the aero-engine in virtue of the rotation of the motor in order to inspect the rotating parts such as blades and the like.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD +1

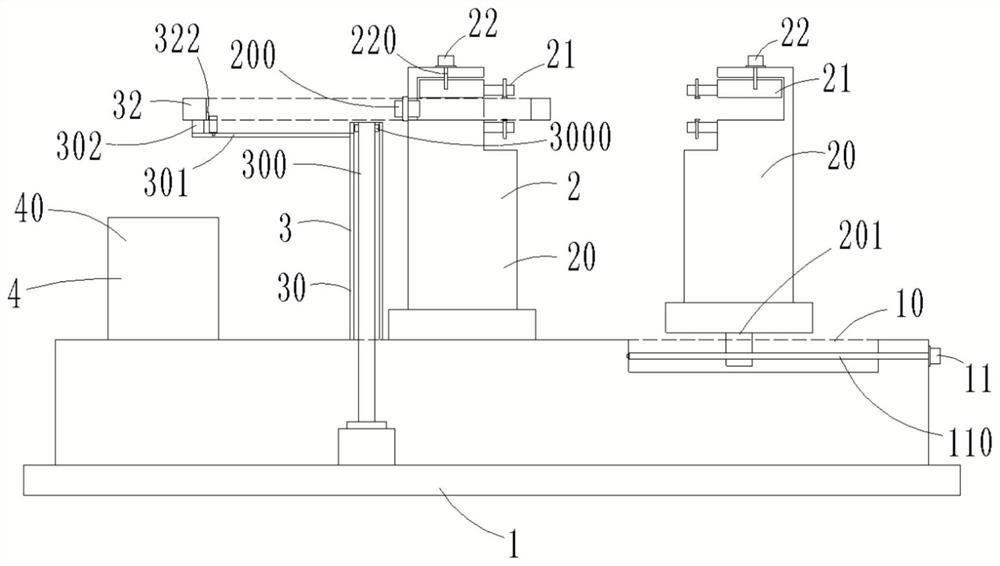

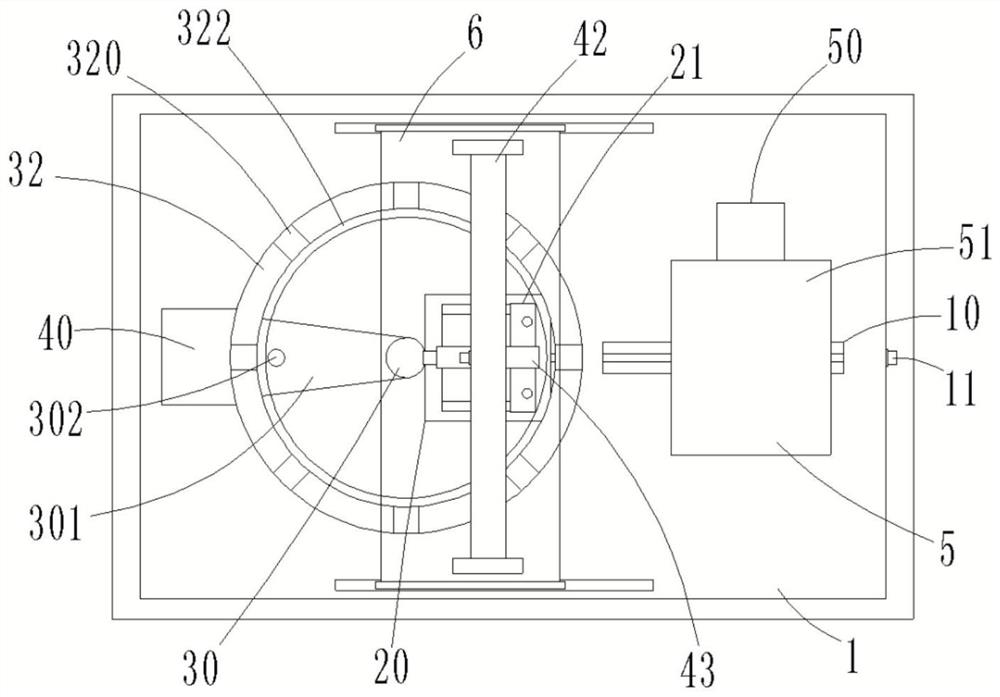

High-precision detection device for aero-engine blade film holes and detection method thereof

PendingCN113670594AEasy transferEasy to storeMachine part testingRadiation pyrometryAviationMechanical engineering

The invention discloses a high-precision detection device for aero-engine blade film holes and a method thereof. The device comprises a detection platform, a blade fixing assembly, a switching assembly, a thermal imaging detection assembly and a controller. The blade fixing assembly, the switching assembly and the thermal imaging detection assembly are all arranged on the detection platform, the blade fixing assembly is used for clamping and fixing engine blades, the switching assembly is located at the front end of the blade fixing assembly and used for conveying the engine blades to the blade fixing assembly, the thermal imaging detection assembly is located on the outer side of the blade fixing assembly and used for detecting the quality of the air film hole in the engine blade, and the controller is electrically connected with each electric device; the device is reasonable in structural design, can perform multi-angle thermal imaging detection on the quality of the engine blade air film hole, has relatively high detection efficiency and accuracy, and is suitable for large-scale popularization.

Owner:宜兴市鑫煜科技有限公司

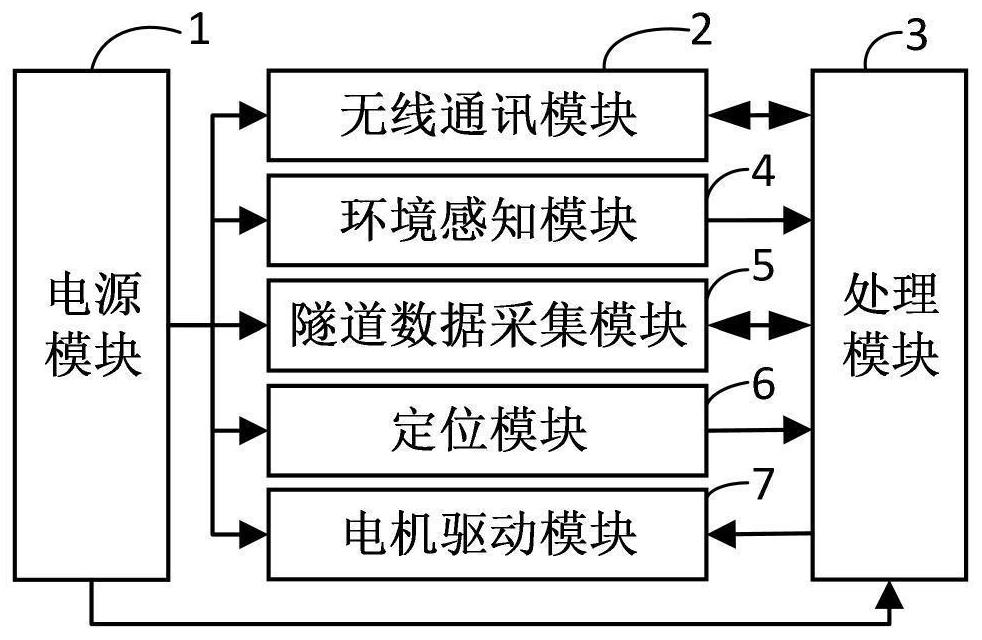

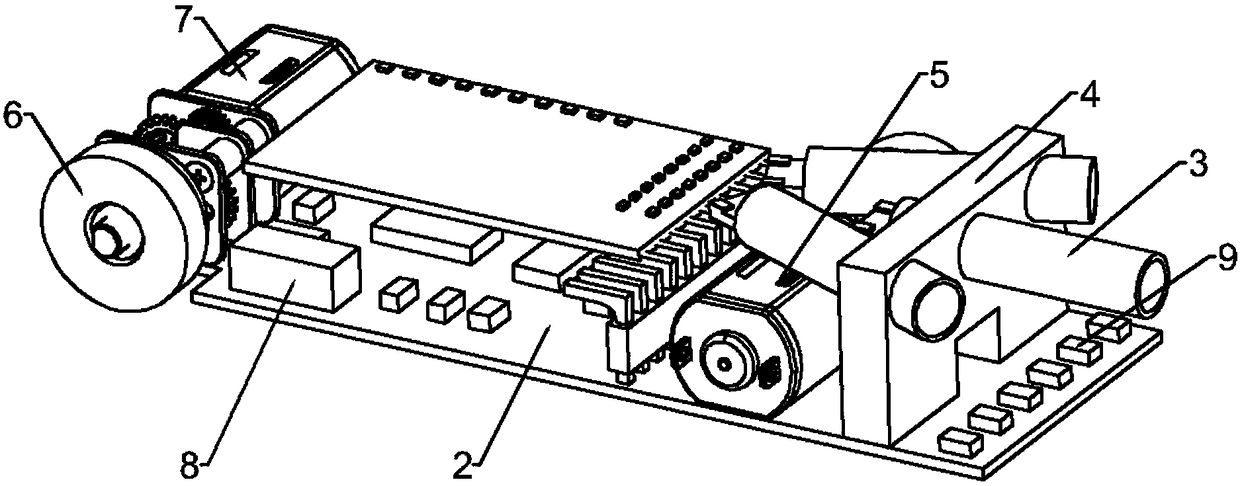

Magnetic adsorption micro vision measuring robot and control system thereof

InactiveCN108536133ASimplify inspection workLow costManipulatorPosition/course control in two dimensionsControl systemRemote control

The invention discloses a magnetic adsorption micro vision measuring robot and a control system thereof. The robot is composed of a remote control handle and a rectangular moving platform. Three cameras and a base fixing the cameras are arranged on the rectangular moving platform. Two driving devices are installed in parallel at the front side and the rear side of the rectangular moving platform in a reverse direction; each driving device includes a composite driving wheel and a driving motor; and the composite driving wheel is formed by combination of a ring-shaped permanent magnet and a rubber wheel. A power source and a lighting lamp are fixedly connected to the rectangular moving platform. Compared with the prior art, the magnetic adsorption micro vision measuring robot has the following advantages: a micro vision measuring robot for measurement in narrow space is provided; the robot is capable of walking in narrow working space or a narrow long pipe and can be absorbed to the magnetic metal surface to realize walking measurement along any direction of the magnetic metal surface; the narrow space measurement is supported; and the detection work is simple, the cost is low, and the efficiency is high.

Owner:创物秦皇岛科技有限公司

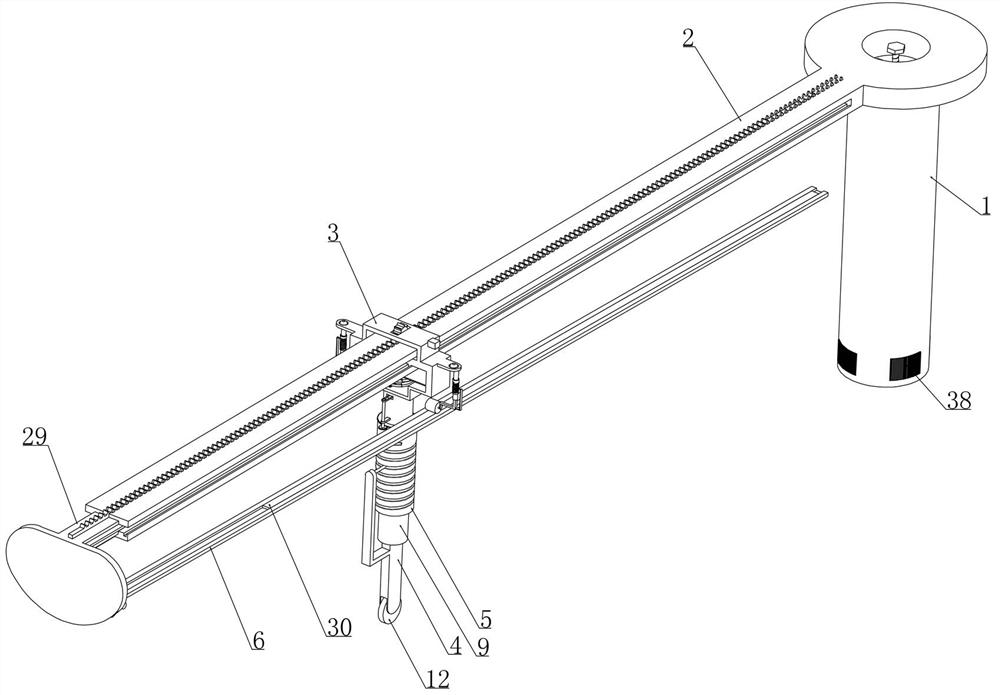

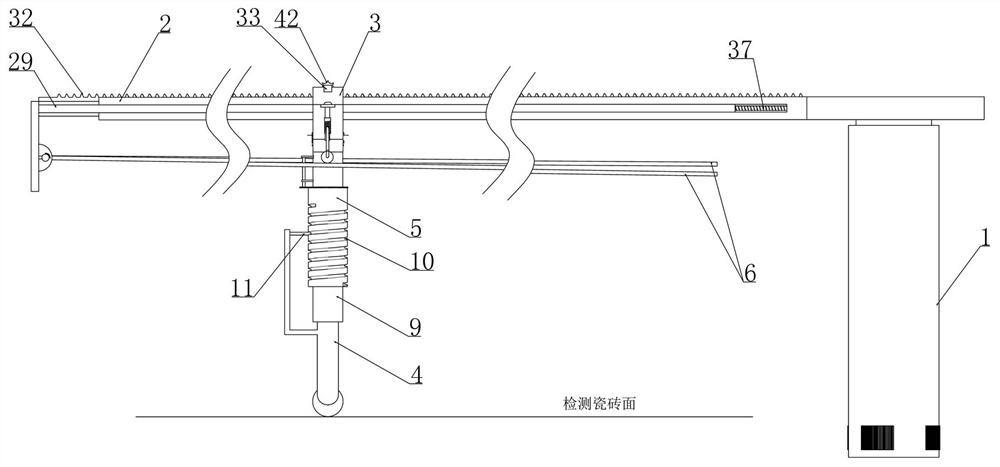

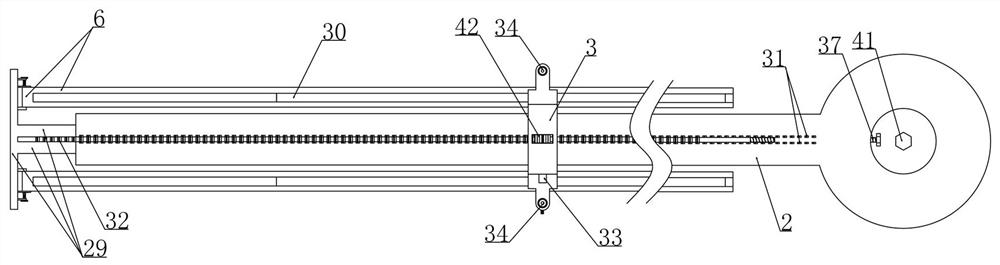

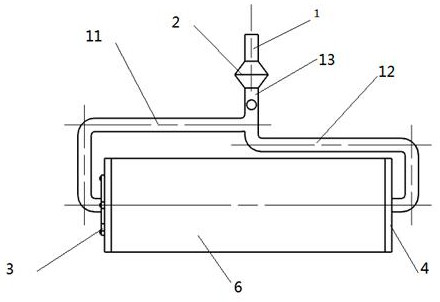

Gradient measuring instrument for constructional engineering floor tiles

InactiveCN113834470AHigh precisionImprove referenceIncline measurementMeasuring instrumentStructural engineering

The invention relates to a gradient measuring instrument for constructional engineering floor tiles. The problems that in the existing floor tile gradient measuring process, the detection process is tedious and inconvenient, and large work intensity is brought to measuring personnel are effectively solved. According to the technical scheme, in the measuring process, a measurer does not need to carefully check a measuring tool with naked eyes, whether the gradient of a detected part meets the requirement or not can be judged only by paying attention to the state of a warning lamp, and in the measuring process, with the floor drain as the center, the gradient of the floor tile is linearly measured on the area with any length as the radius, and compared with traditional sectional detection, the gradient measuring instrument has the advantages that the precision of the detection result is greatly improved, and the reference of the detection result is higher.

Owner:HUANGHE S & T COLLEGE

Quality control method for Jinfozhitong pill

ActiveCN1588081ALow backgroundClear spotsComponent separationColor/spectral properties measurementsPaeoniflorinCITRUS MEDICA FRUIT

The invention discloses a quality control method for gold Buddha analgetic pill, it increases thin layer chromatography incrimination method of white peony root, corydalis tuber based on original fingered citron incrimination. It also uses high efficiency liquid chromatography incrimination method to detect the content of the paeoniflorin. The control method of the invention upgrades the accuracy, effectiveness of control, and it realizes the effective control of the product.

Owner:GUANGZHOU BAIYUNSHAN ZHONGYI PHARMA COMPANY

Rapid fire weapon barrel anti-ablation wear test method and device

ActiveCN108562507BImprove accuracySimplify inspection workMaterial thermal analysisInvestigating abrasion/wear resistanceThermodynamicsEngineering

The invention provides an experiment method and device for ablation and abrasion resistance of rapid-fire weapon barrels. The method comprises the steps that 1) an experiment device is prepared, wherein the device comprises a pipe, an explosion shock explosive box or an explosive feeding port, a heating device and a high-pressure gas device; 2) the rapid-fire weapon barrels are connected to the two ends of the pipe respectively, and inner cavities are communicated with an inner cavity of the pipe separately to form a sealed gas channel; the rapid-fire weapon barrels and the heating device arecooperatively installed; 3) explosion shock explosive is heated or ignited, and a burning compound is obtained through burning; 4) high-pressure gas and the burning compound enter the inner cavities of the rapid-fire weapon barrels; 5) the rapid-fire weapon barrels are heated and cooled to obtain the rapid-fire weapon barrels. According to the method, from three aspects of the temperature, atmosphere and abrasion, the real environment where bullets or cannonballs penetrate through the barrels is simulated, the accuracy of a detection result is improved, the detection work is simplified, and the working efficiency is high; the experiment cost is lowered, the labor amount is greatly lowered, and the labor cost is reduced.

Owner:CHONGQING UNIV OF TECH

Device and method for detecting aviation conduit gap

ActiveCN112033334ASolve measurement inefficienciesSolve the problem of not being able to measure accurate valuesMeasurement devicesAviationStructural engineering

The invention provides a device and method for detecting an aviation conduit gap. A probe is arranged to perform detection conversion on the positions of two conduits so as to obtain the conduit gap.Through the arrangement, the device special for detection is provided, rapid, simple, convenient and accurate detection is achieved, and the detection efficiency and precision are improved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

A terminal service method and device

The invention provides a terminal service method and device which are applied to network equipment arranged between a mobile terminal and an agent server. The method comprises the following steps: step A, receiving and storing a conversion ACL rule assigned by an administrator through a management channel, wherein the conversion ACL rule is used for filtering out an IP message which is specified by the administer and has a target IP address belonging to a specified network segment; step B, checking whether the IP message matches the conversion ACL rule, if so, skipping to step C for processing; and step C, correspondingly converting the target IP address and the destination port of the IP message into the IP address of a specified agent server and a specified port, and sending the modified IP message to the agent server. Compared to the prior art, by using the terminal service method and device, the work assigned by the NAT configuration of the administrator is greatly simplified, and the checking and inspection work of the administer in maintaining the NAT configuration can also be substantially simplified.

Owner:NEW H3C TECH CO LTD

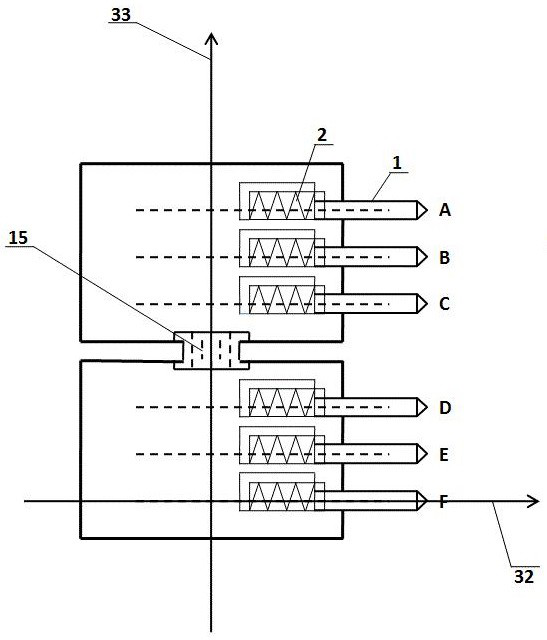

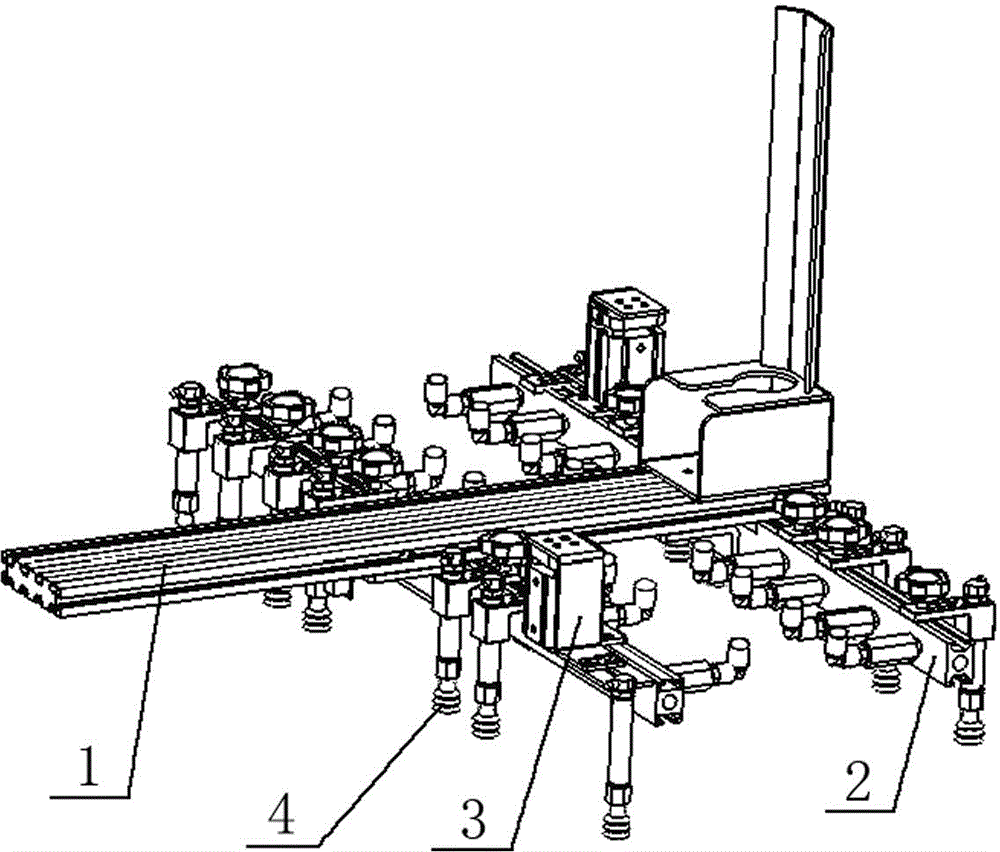

Vacuum adsorption system of full-automatic board receiving machine

ActiveCN103010805BMeet the requirements of production efficiencyClean and reliable transportArticle deliveryPulp and paper industryPrinted circuit board

The invention discloses a vacuum adsorption system of a full-automatic board receiving machine. The vacuum adsorption system comprises an adsorption support, vacuum generators, a vacuum valve terminal and vacuum nozzle groups, wherein the vacuum generators are strip-shaped vacuum generators, and at least two vacuum generators are arranged on the adsorption support and are vertical to the adsorption support; the vacuum nozzle groups are composed of seven to ten nozzles and are uniformly arranged on the vacuum generators, and one vacuum valve terminal is also arranged on the vacuum generators; and the vacuum gas ports of the vacuum generators are connected with the vacuum valve terminal though air passages. The highest production speed of the vacuum adsorption system is 12 pcs / min, and the vacuum adsorption system can meet the requirement of production efficiency of the PCB (Printed Circuit Board) and is highly automatic. The vacuum adsorption system can effectively ensure the clearness and the reliable transport of the PCB, the size of the absorbed largest plate is 28*24 inch, the size of the smallest plate is 10*10 inch, and the thickness capable of absorbing the PCB is 0.1-4 mm.

Owner:SHANGHAI KAISER ELECTRONICS

An inspection method for an automatic inspection system of an exchange

ActiveCN105072056BImplement automatic connectionSimplify workData switching networksComputer moduleComputer terminal

The present invention discloses a switch automatic inspection system and an inspection method thereof. The system comprises a database module, a switch control module and a report generation module. The database module is used for storing an inspection rule, switch configuration information and switch command information. The switch control module is used for connecting a switch and obtaining the operating parameter of the switch and an inspection result. The report generation module reads the inspection result and generates an inspection report based on the inspection rule. According to the inspection system and the inspection method, a terminal, a corresponding switch and a port can be rapidly obtained, thus the working of network operation and maintenance staff is simplified, the working efficiency is improved, and a lot of labor costs are saved.

Owner:STATE GRID CORP OF CHINA +1

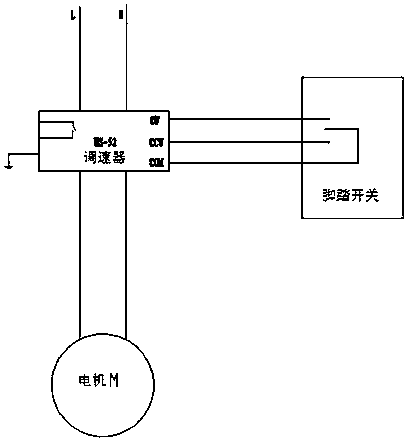

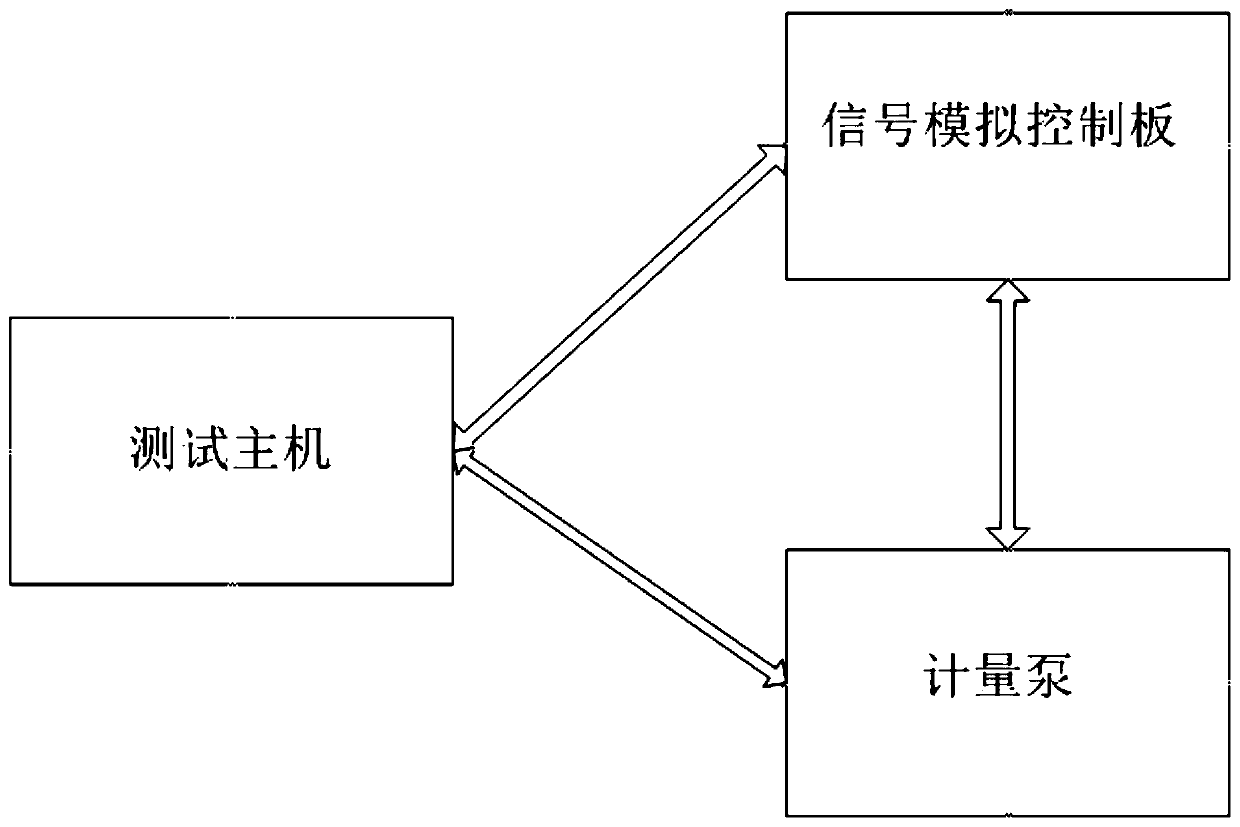

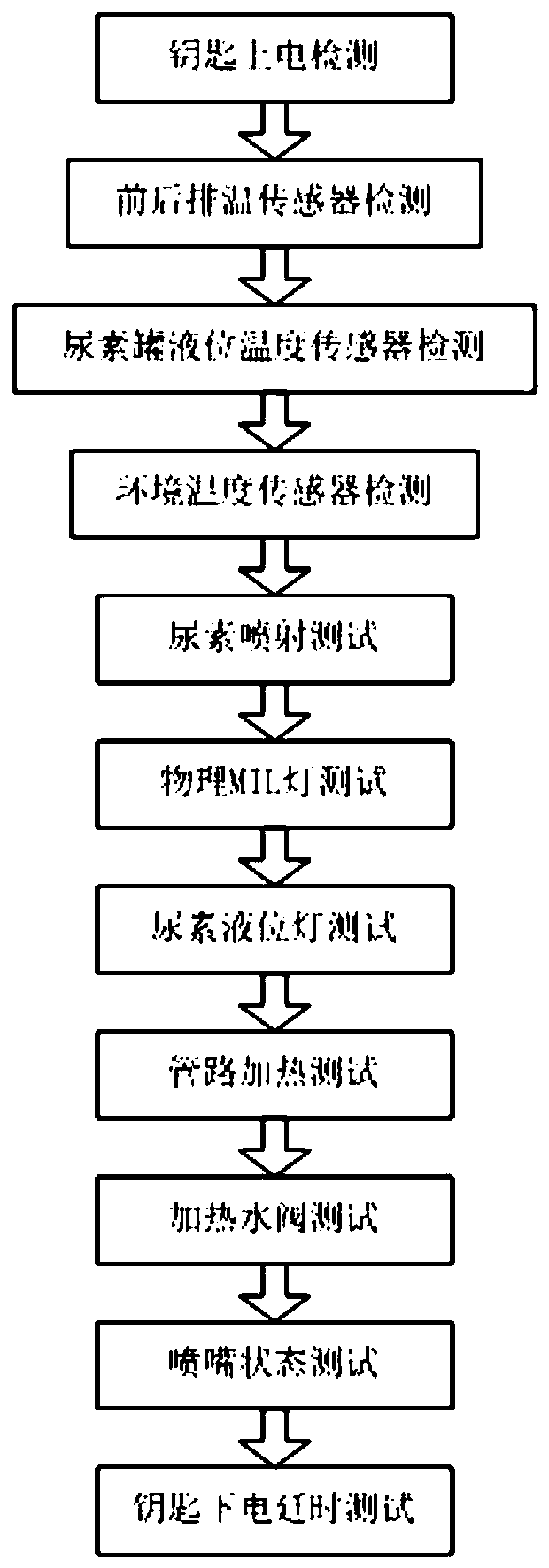

An off-line test bench for scr metering pumps

ActiveCN108223348BReduce use costSimplify inspection workPump testingPositive-displacement liquid enginesControl signalMetering pump

The invention discloses a SCR metering pump offline testing stand which comprises a testing host, a SCR control communication wiring harness, a signal simulation control panel and a to-be-tested metering pump. The testing host is connected with the signal simulation control panel and the to-be-tested metering pump through the SCR control communication wiring harness, controls the signal simulationcontrol panel to collect signals, controls the to-be-tested metering pump to work, monitors state of the metering pump and each part of a PCB thereof at the same time, sends corresponding request functions to the signal simulation control panel and the metering pump to test the corresponding functions and judges whether the metering pump and the PCB thereof are normal or not by analyzing signalsfed back by the signal simulation control panel and the metering pump. The SCR metering pump offline testing stand is low in manufacturing cost and resource consumption, convenient to operate and stable and reliable in testing result and is an essential tool for conducting metering pump researches and good equipment for SCR technology related manufacturers to conduct metering module testing.

Owner:KAILONG HIGH TECH

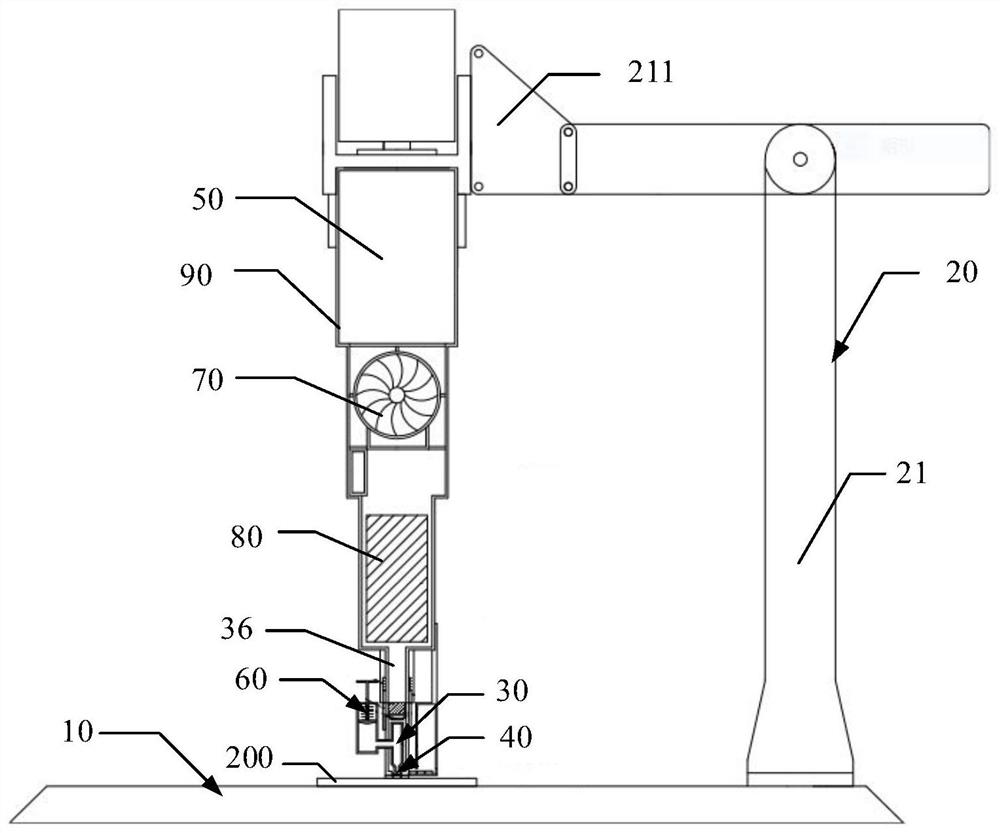

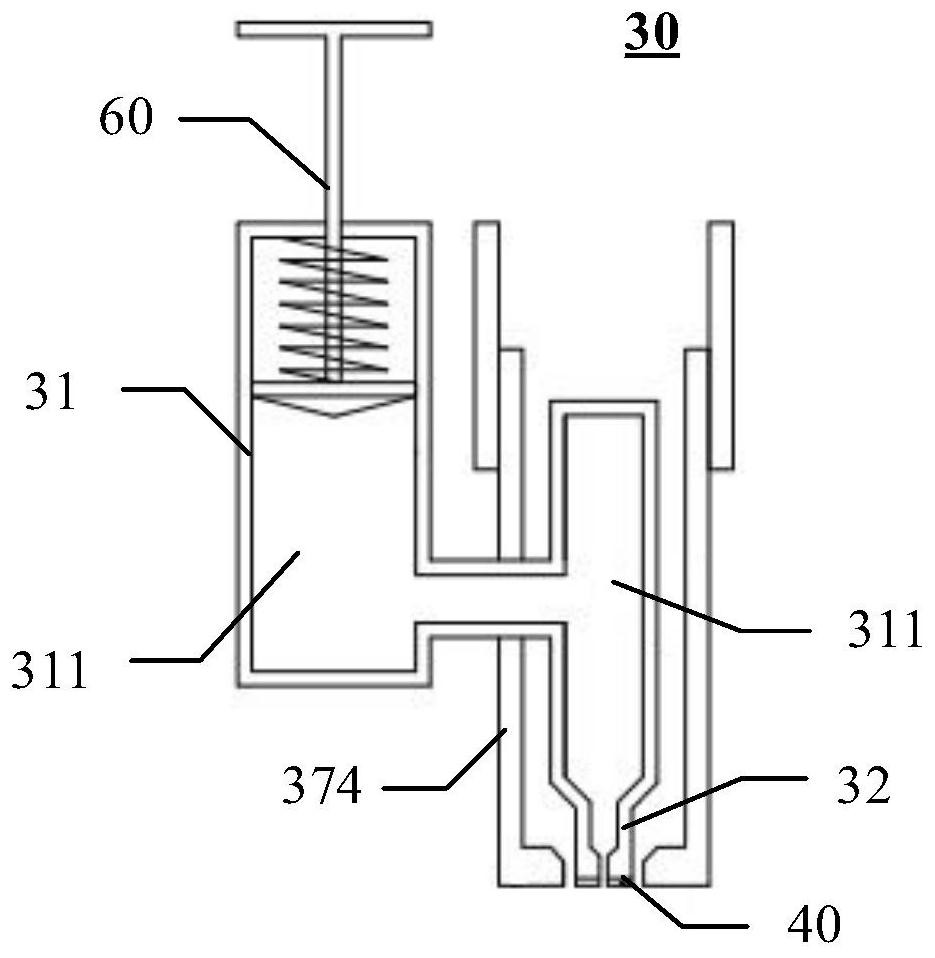

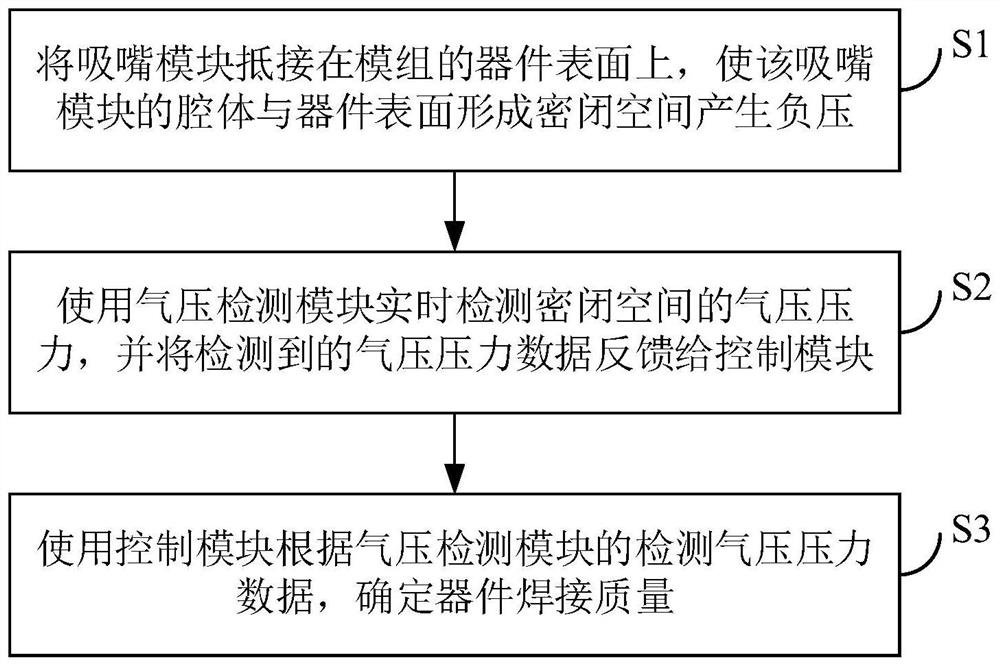

Device, method, equipment and storage medium for detecting welding quality of devices

ActiveCN111044235BSimplify inspection workNo human intervention requiredMeasurement of fluid loss/gain rateDevice formControl engineering

Owner:SHENZHEN LAMP TECH +1

System and method for detecting spatial size of special-shaped part

PendingCN110631447AReduce cost inputSimplify inspection workMechanical measuring arrangementsAbnormal shapedCushion

The invention discloses a system and method for detecting the spatial size of a special-shaped part. The system comprises the special-shaped part, a reference working platform, a base, a core shaft, acushion block and a size detection assembly; the special-shaped part comprises a special-shaped part plate surface; the base is arranged at the left side of the top of the reference working platform;the size detection assembly comprises a support sliding base and a dial gauge; the support sliding base is glidingly installed at the right side of the top of the reference working platform; the cushion block is arranged on the top of the reference working platform; the core shaft positioned between two shaft sleeve parts is located and installed in a semicircular groove of the base in a matchedmanner; the edge of the plate surface of the special-shaped part plate surface is put on the top of the cushion block in a contact manner; and the end part of a measurement needle of the dial gauge iscorrespondingly contacted with the surface of the special-shaped part plate surface. According to the system and method for detecting the spatial size of the special-shaped part in the invention, thespecial-shaped part is located through the base, the core shaft, the cushion block and the reference working platform in a standard manner; then, the support sliding base is moved; furthermore, the dial gauge is driven to move; and thus, detection of the spatial size of the outside surface of the special-shaped part plate surface of the special-shaped part can be realized.

Owner:成都威诺精密机械有限公司

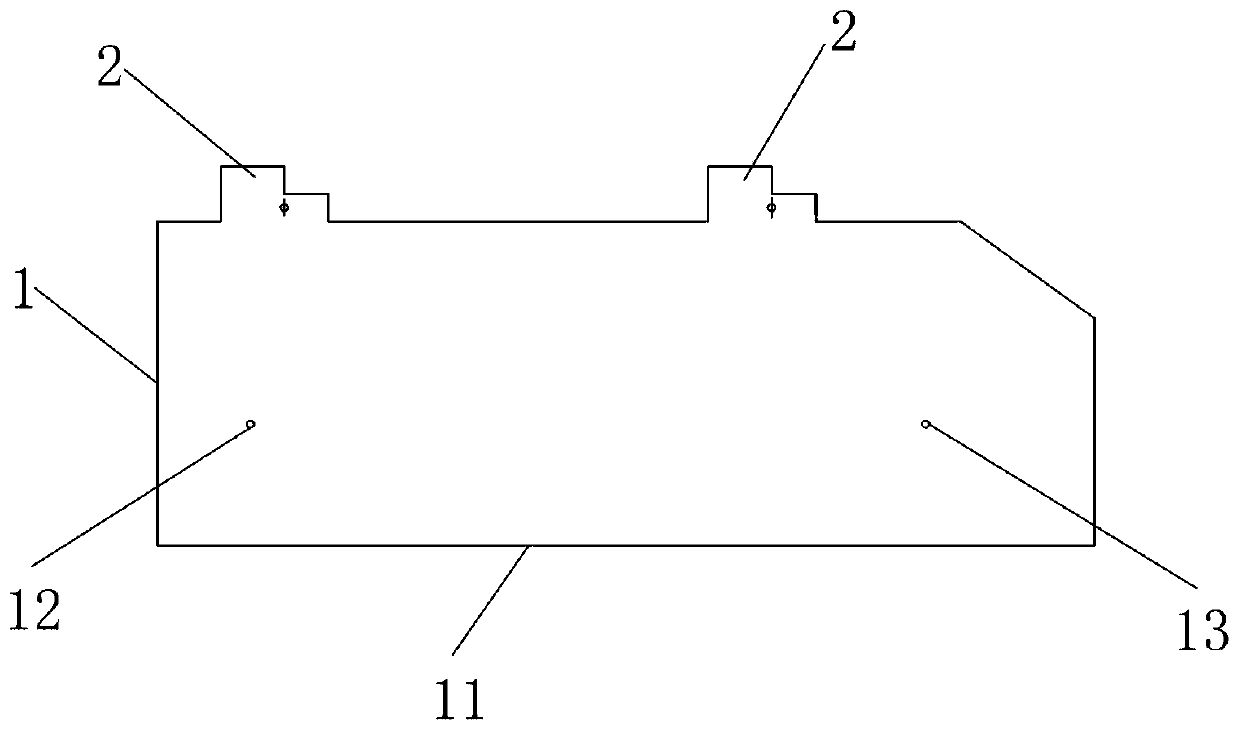

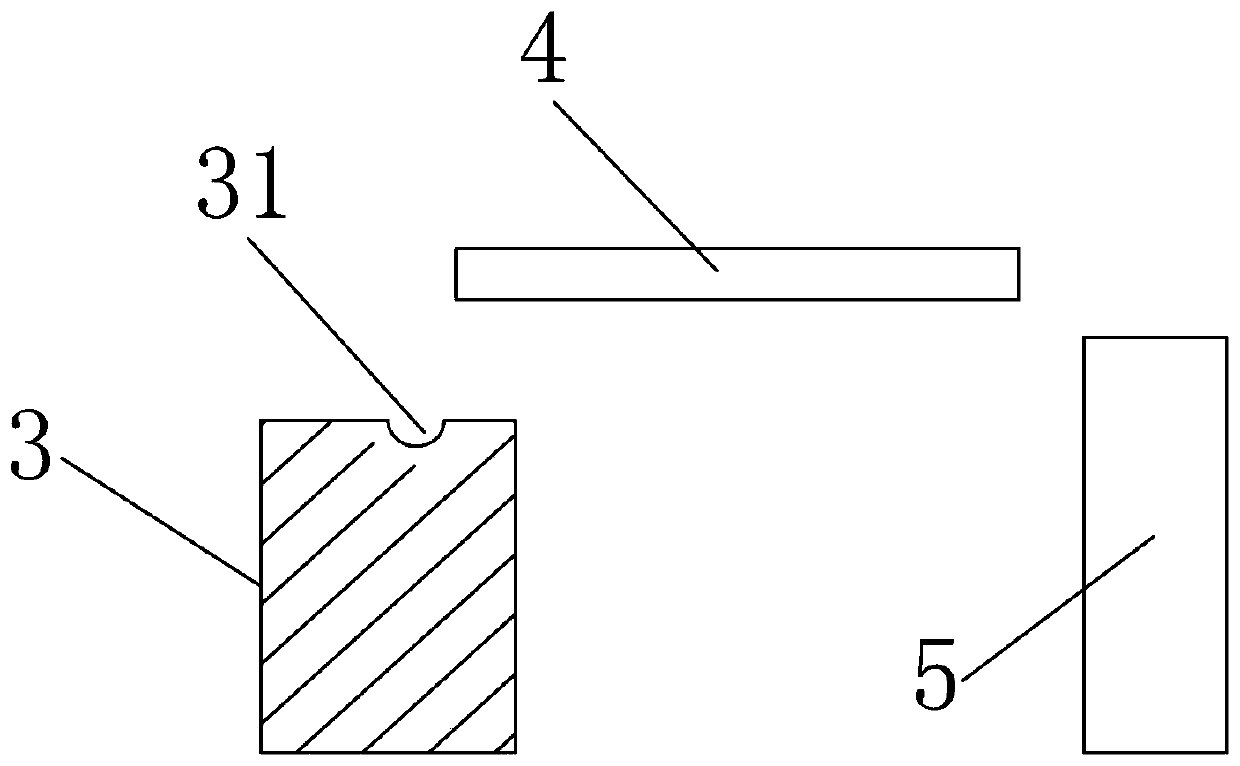

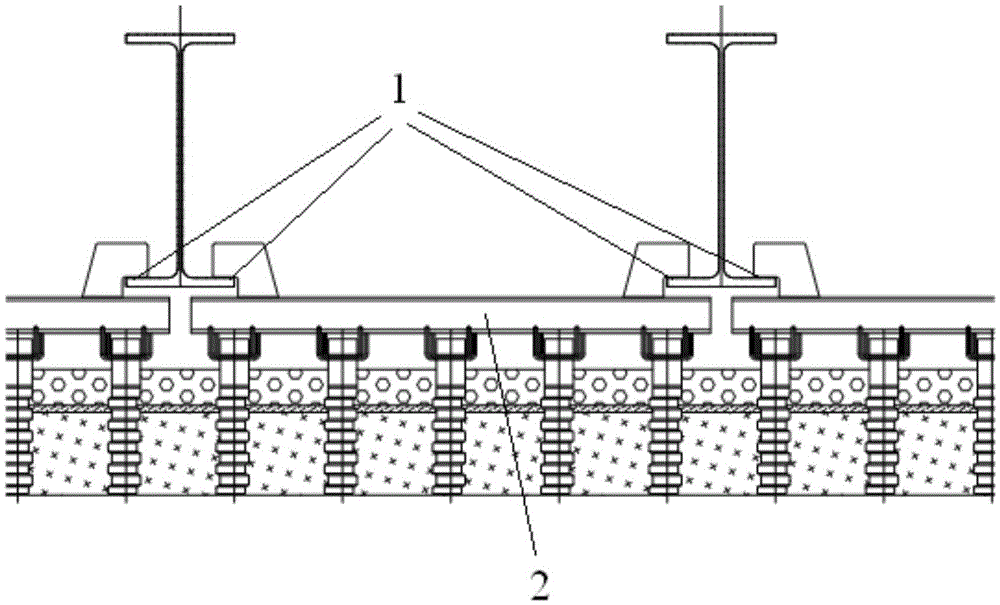

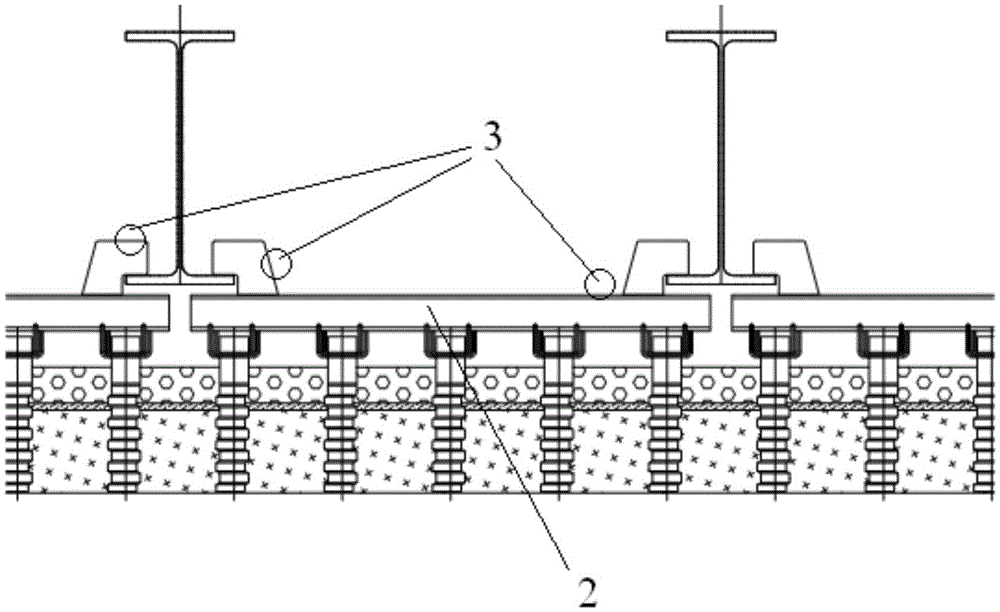

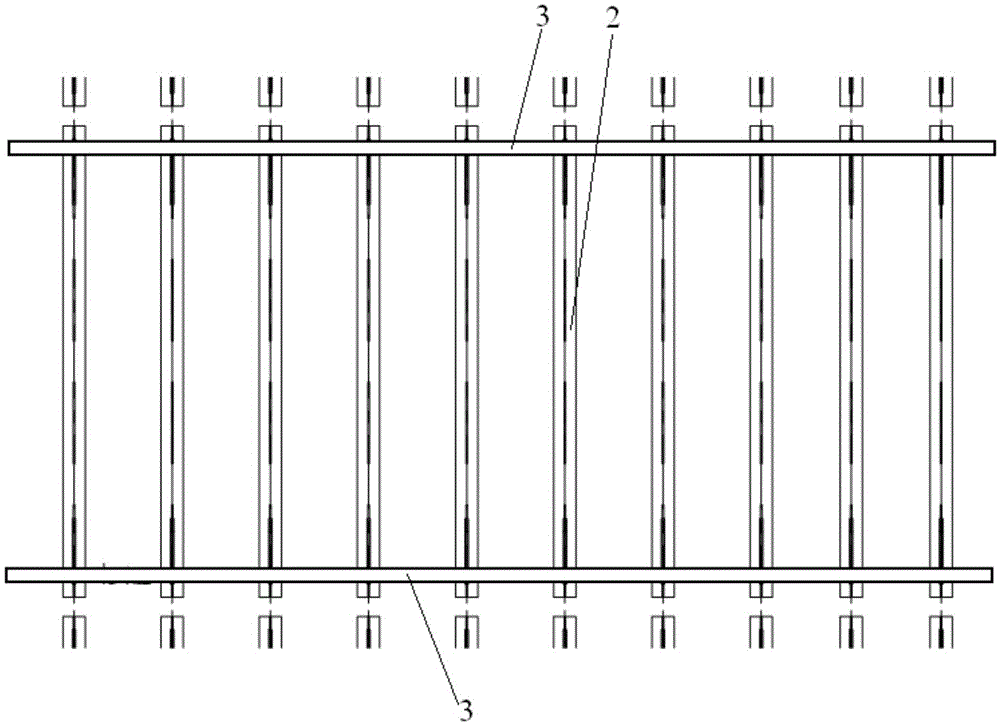

A construction method for the construction structure of a heating furnace roof hanging beam

ActiveCN103575111BGuaranteed free expansionLower quality requirementsLining supportsWork periodFree expansion

The invention discloses a construction method for a construction structure of a suspended beam at the top of a heating furnace. The construction structure comprises a plurality of parallel and level I-steel (2) distributed on the same plane at intervals, wherein connecting steel bars (3) are arranged at the end parts of the I-steel (2) and connected with the I-steel (2) in a fastened manner. The invention further discloses the construction method for the construction structure of the suspended beam at the top of the heating furnace. According to the technical scheme, the problems in the prior art are effectively solved, the cutting operation is complete when welding points are removed, the inspection operation is easy, efficient and simple, free expansion of the I-steel is effectively guaranteed, and the requirement on the quality of workers is lowered; the construction structure is firm to fix, convenient to clean and high in framework supporting speed, shortens the work period and improves the construction quality.

Owner:芜湖新兴新材料产业园有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com