Vacuum adsorption system of full-automatic board receiving machine

A technology of vacuum adsorption system and automatic board receiving machine, which is applied in the direction of sending objects, thin material processing, transportation and packaging, etc., which can solve the problems of inability to ensure clean and reliable transportation of PCBs, low production efficiency, etc., and achieve cleanliness and reliability Transport, simplify commissioning, and ensure easy wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

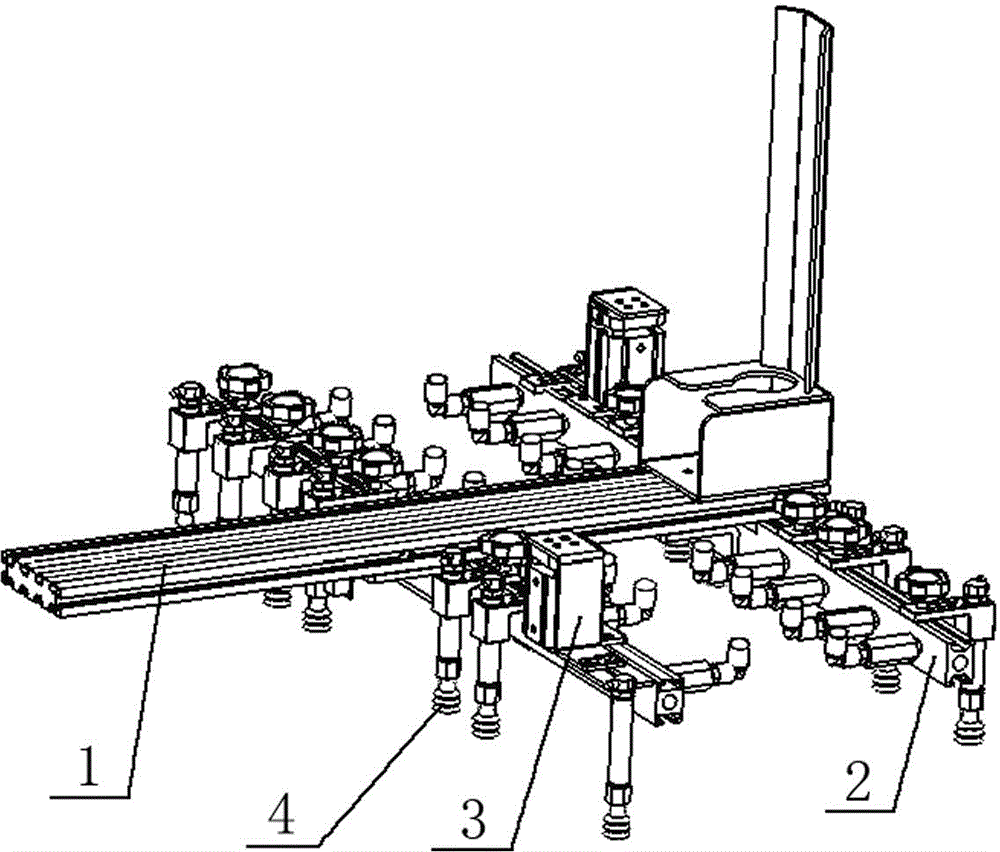

[0013] Such as figure 1 As shown, a vacuum adsorption system of a fully automatic plate receiving machine includes an adsorption bracket 1, a vacuum generator 2, a vacuum valve island 3 and a vacuum suction nozzle group; the vacuum generator 2 is a strip-shaped vacuum generator, which is Two vacuum generators 2 are arranged on the support 1, and the vacuum generator 2 is vertically arranged with the adsorption bracket 1. The vacuum nozzle group is composed of 7 suction nozzles 4, and the vacuum nozzle group is evenly arranged on the vacuum generator 2. The generator 2 is also provided with a vacuum valve island 3, and the vacuum port of the vacuum generator 2 is connected with the vacuum valve island 3 through an air channel. A fixing groove capable of fixing the vacuum suction nozzle group is arranged on the vacuum generator 2 .

[0014] The working principle of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com