Locomotive and electric appliance screen cabinet thereof

A technology for electrical screen cabinets and locomotives, which is applied to locomotives, substations/power distribution equipment shells, etc., and can solve problems such as not considering the vertical direction, box jumping, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in principle below in conjunction with the embodiments and accompanying drawings.

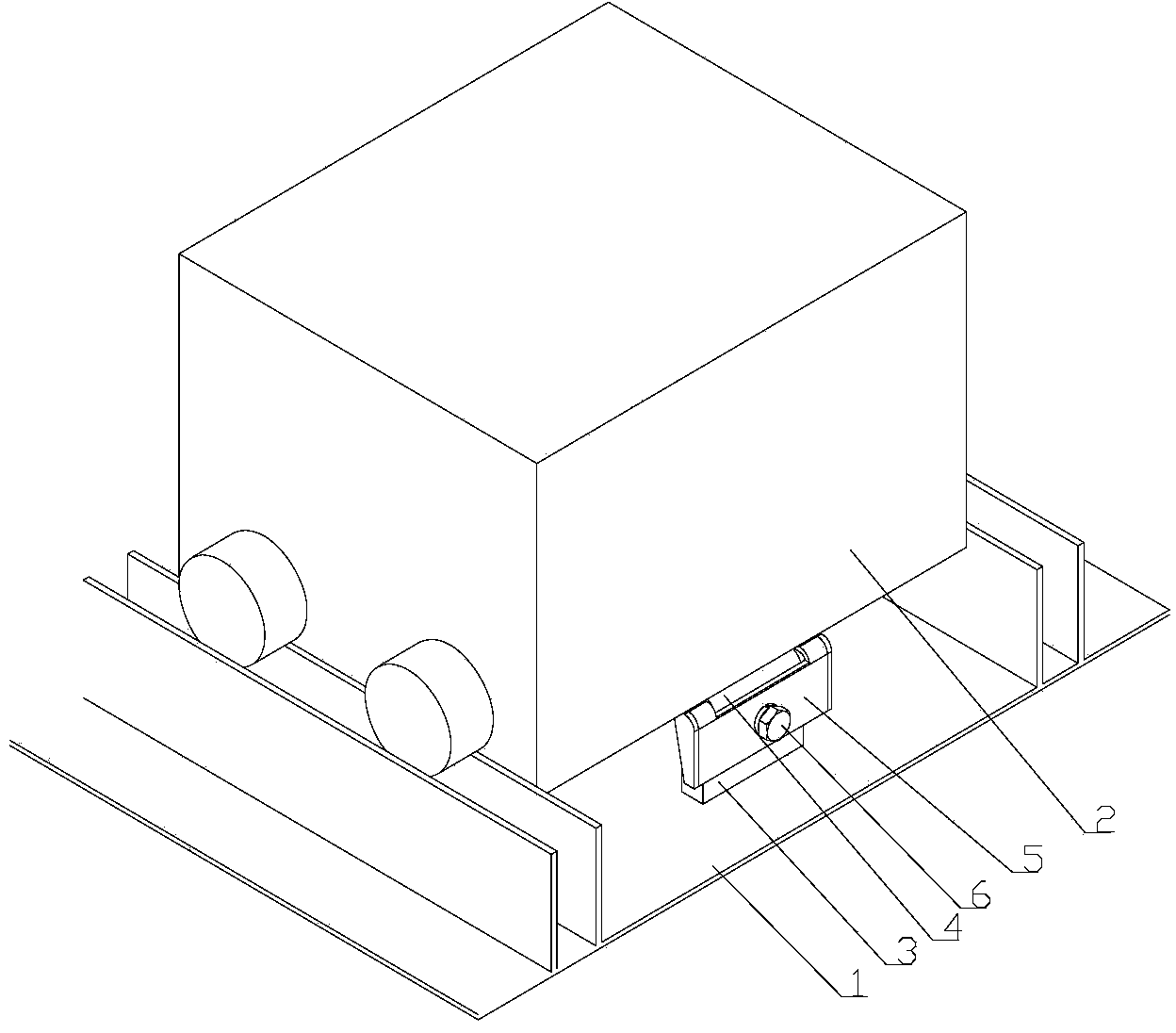

[0026] figure 1 It is the overall axonometric drawing when the cabinet is fixed on the electrical screen cabinet in the embodiment of the present invention. It can be seen from the figure that there are rollers installed under the cabinet 2, and guide rails are arranged on the cabinet body 1 of the electrical screen cabinet. When the cabinet needs to be overhauled When the working device in the cabinet is pulled out, the rollers on the lower side of the cabinet 2 move along the guide rails and leave the cabinet 1. In order to ensure the safe operation of the locomotive, after the overhaul is completed, the box body 2 is installed back in the cabinet body 1 for limit installation. In this embodiment, the limit of the box body i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com