A main junction box support of an exdiic flameproof motor

A main junction box, explosion-proof technology, applied in the field of main junction box supports, can solve the problems of small space, inability to completely exchange motors, and inability to install the main junction box supports, etc., to achieve the effect of saving mold costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the technical solutions of the present invention, specific embodiments will be described in detail below in conjunction with the accompanying drawings.

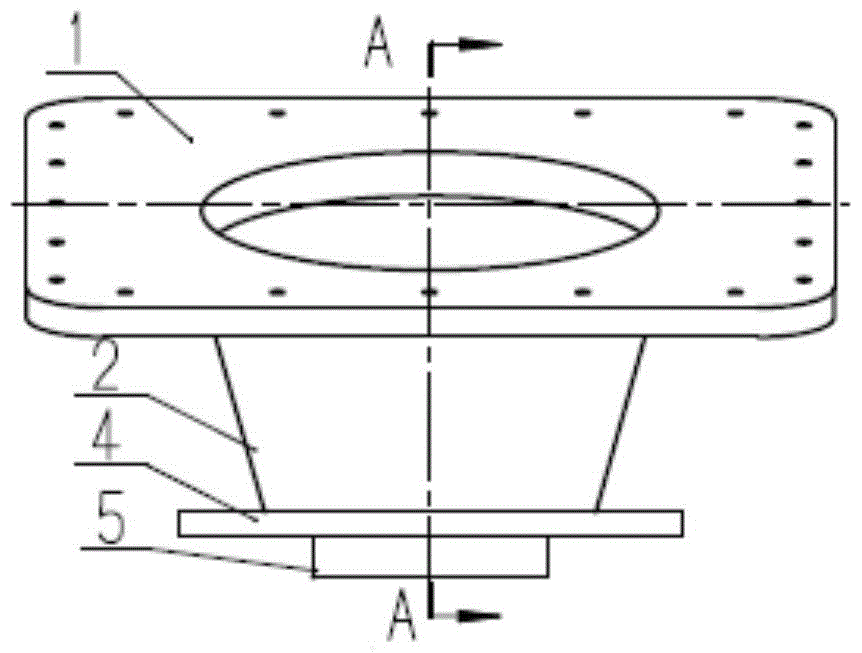

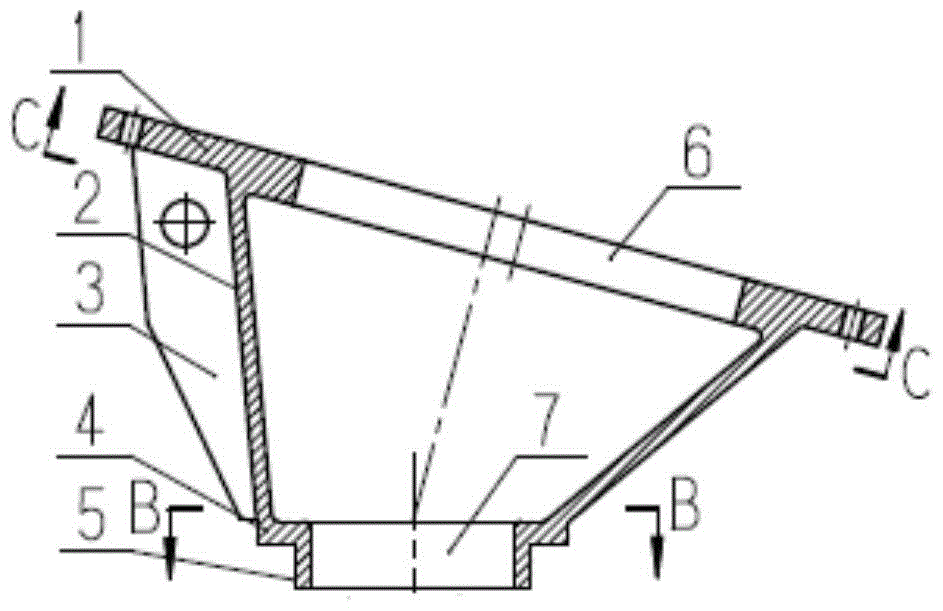

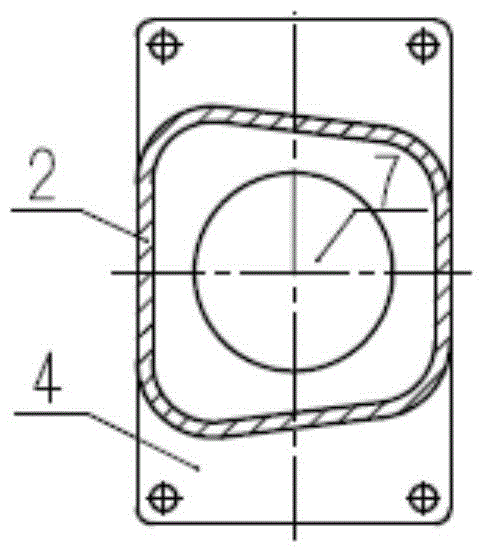

[0026] see Figure 1 to Figure 4 , an embodiment of the present invention, a main junction box support of an Exd II C flameproof motor adopts a shell structure, including a bottom mounting plane 4 , a top mounting plane 1 and a shell wall 2 .

[0027] The bottom installation plane 4 is arranged horizontally, the bottom installation plane 4 is rectangular, and the middle part of the bottom installation plane 4 is provided with a wire inlet 7, and the middle part of the bottom installation plane 4 is connected with a downward protruding circular outer stop 5, and the wire inlet The port 7 is set coaxially with the outer spigot 5; the top installation plane 1 is set obliquely and is located above the bottom installation plane 4, and the angle formed by the extension surface of the top install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com