Draw gear of bogie of railway vehicle

A rail vehicle and traction device technology, which is applied to bogies, devices that move laterally between the bogies and bogies, and underframes, can solve problems such as stiffness characteristics that cannot fully meet design requirements, and fatigue damage to rubber nodes. To achieve variable traction stiffness performance and improve ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

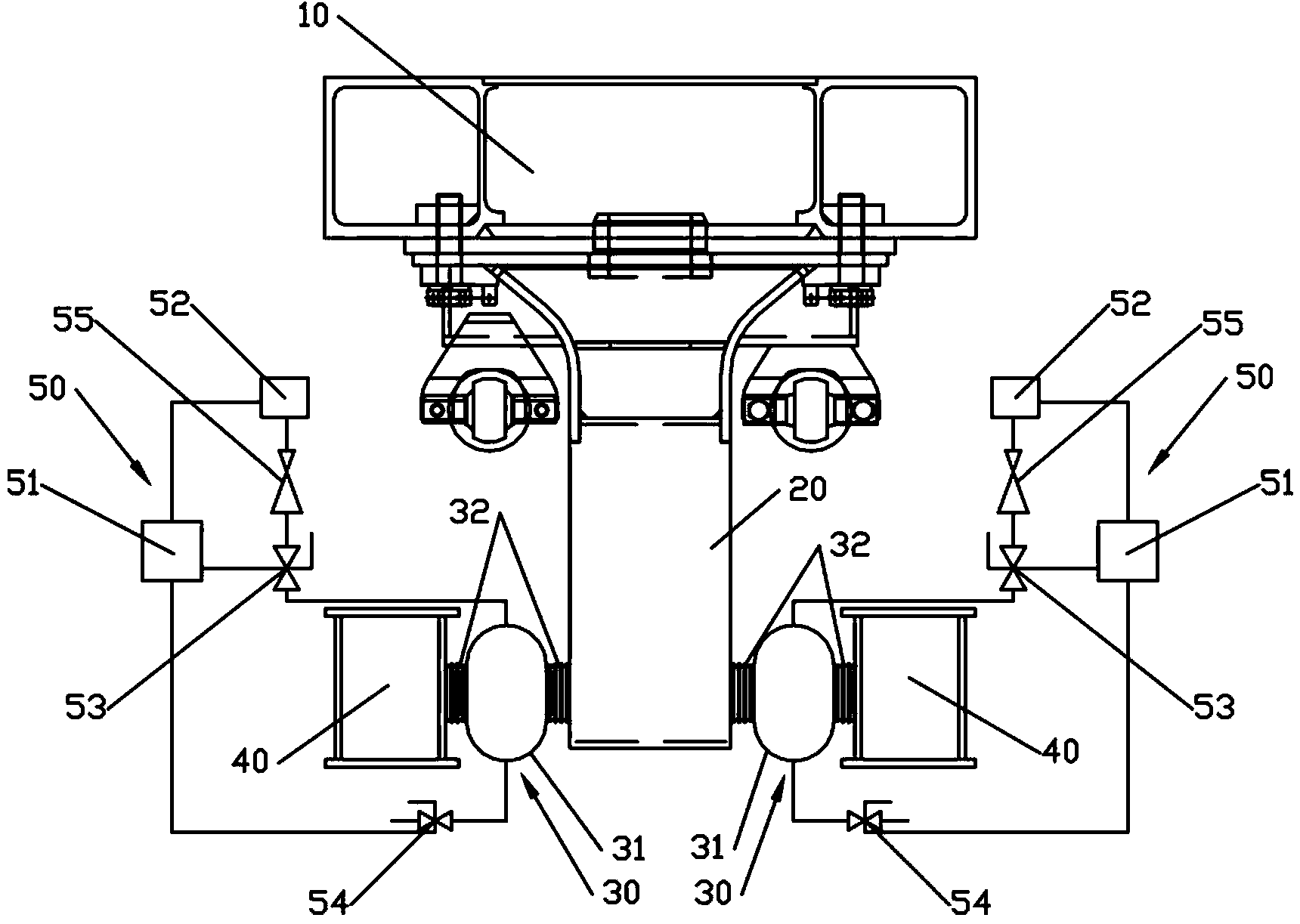

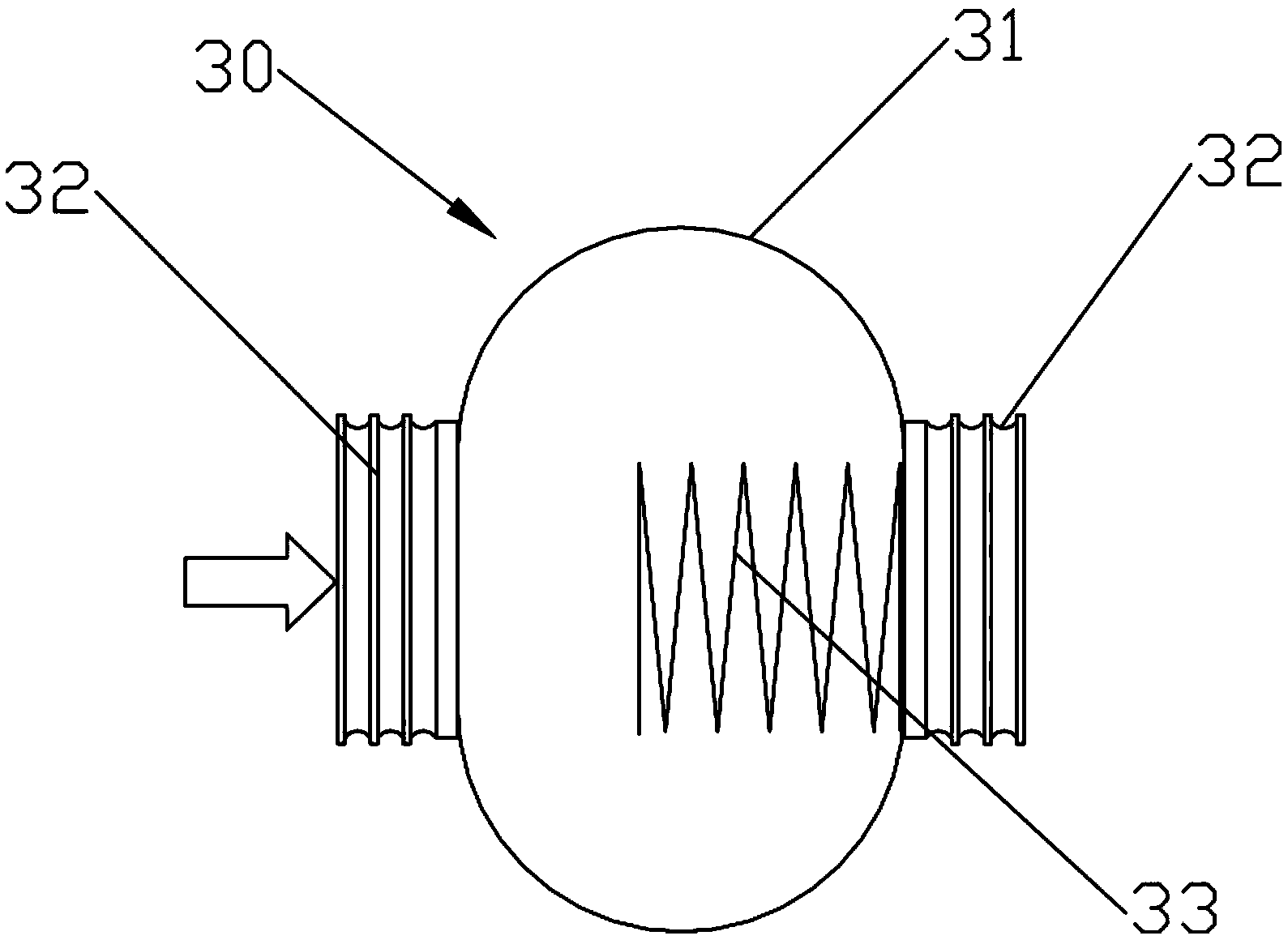

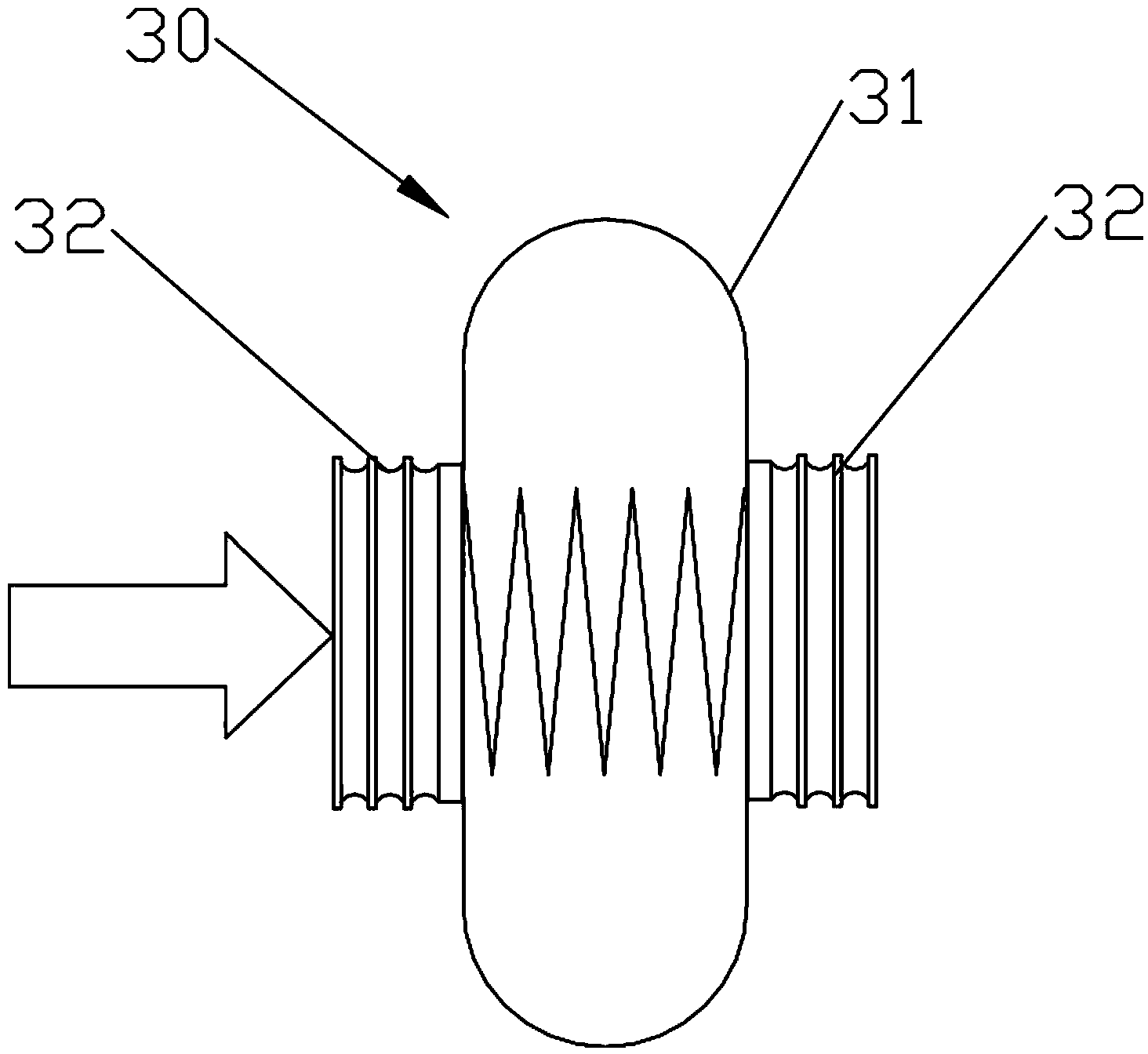

[0025] refer to figure 1 As shown, the railway vehicle bogie traction device of the present invention includes: a central pin 20 and two traction capsules 30; each traction capsule 30 includes a traction rubber pile 32 and a capsule 31, and the body of the capsule 31 is made of rubber. It is provided with a filling port, the capsule 31 is filled with fluid, and the fluid in the capsule 31 is gas or liquid. In this embodiment, the fluid in the capsule 31 is compressed air, and the pressure of the capsule 31 can be set. The traction rubber stack 32 is composed of multiple rubber sheets stacked in sequence to form a columnar structure. The traction rubber stack 32 is connected to the capsule 31 through a flange or glue joint. When the traction rubber pile 32 is connected to the capsule 31 , the axial direction of the traction rubber pile 31 is perpendicular to the capsule 31 , that is, the axis extension of the traction rubber pile 32 passes through the capsule 31 . In this emb...

Embodiment 2

[0033] This embodiment is basically the same as Embodiment 1, except that the rail vehicle bogie traction device in this embodiment also includes a center pin seat, which is rotatably socketed on the center pin; two traction capsules The components are respectively connected with the center pin seat, arranged in a "Z" shape. After installation, the two traction capsules 30 are located on the same level.

[0034] The railway vehicle bogie traction device is located between the frame 40 and the center pin 20 installed on the lower surface of the car body underframe bolster 10 (longitudinal installation), that is, the center pin 20 is fixed on the lower surface of the car body underframe bolster 10 through a bolt assembly. On the surface, the two traction capsules 30 are respectively connected to the front end and the rear end of the frame 40 . The longitudinal stiffness of the capsule 31 can be achieved by setting the inflation and deflation of the pressure control system 50 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com