A hydraulic safety clamping device for experimental electronic equipment

A technology of electronic equipment and clamping device, which is applied in the field of hydraulic safety clamping device for experimental electronic equipment, which can solve the problems of small deformation of the clamping device, not suitable for short-distance bending, excessive force on the screen, etc., and achieve an adjustable range Large, easy to manufacture, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

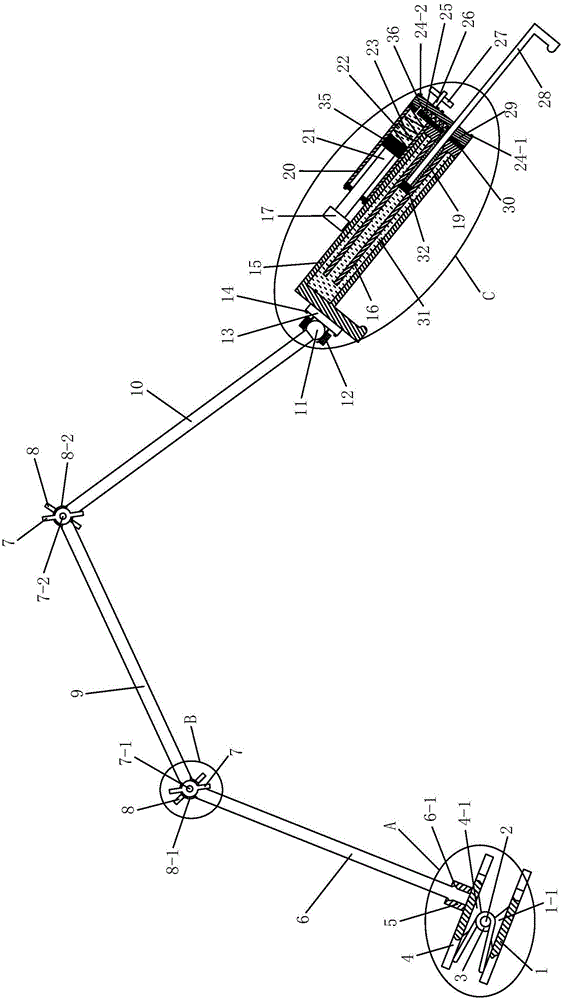

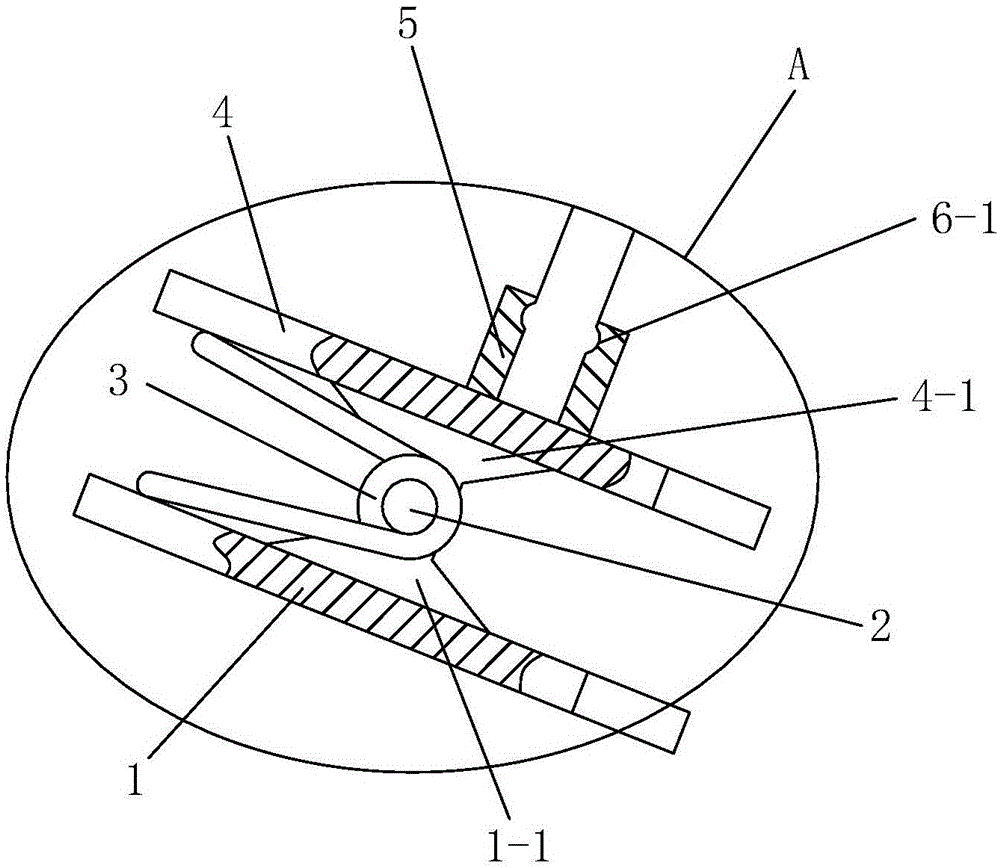

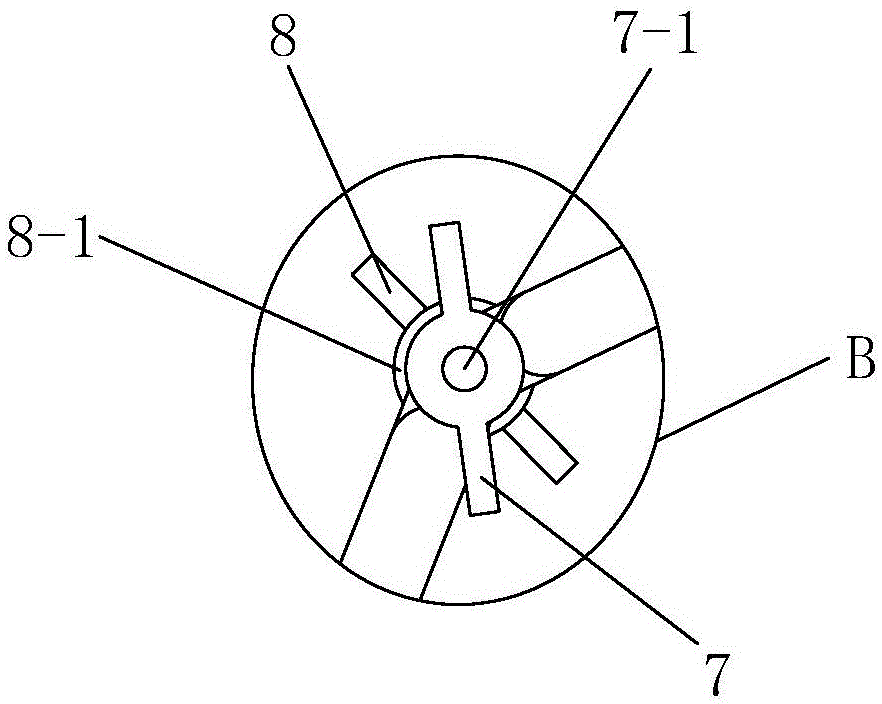

[0043] Such as Figure 1 to Figure 6As shown, the present invention includes a fixed clip, a connecting rod group and a clamping mechanism connected in sequence, the top of the fixed clip is fixed with a shaft sleeve 5, and one end of the connecting rod group extends into the shaft sleeve 5 and is connected with the shaft sleeve 5 Rotationally connected, the other end of the connecting rod group is fixed with a universal ball 11, and the clamping mechanism includes a clamping cylinder 15, an inner cylinder 16, a clamping rod 28, a booster cylinder 20 and a booster rod 21 , the top of the clamping cylinder 15 is fixed with a universal ball base 13, the universal ball 11 is arranged in the universal ball base 13, and the clamping cylinder 15 is sleeved on the inner cylinder 16, The lower end of the inner cylinder 16 is located outside the clamping cylinder 15, and the bottom of the inner cylinder 16 is provided with a leak-proof baffle 30, and the bottom of the leak-proof baffle...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap