Windscreen wiper system

A technology of wiper and wiper blade, which is applied in vehicle cleaning, vehicle maintenance, transportation and packaging, etc. It can solve the problems that the rubber strip and the windshield cannot form a seal, increase the maintenance workload, and increase the user's expenditure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

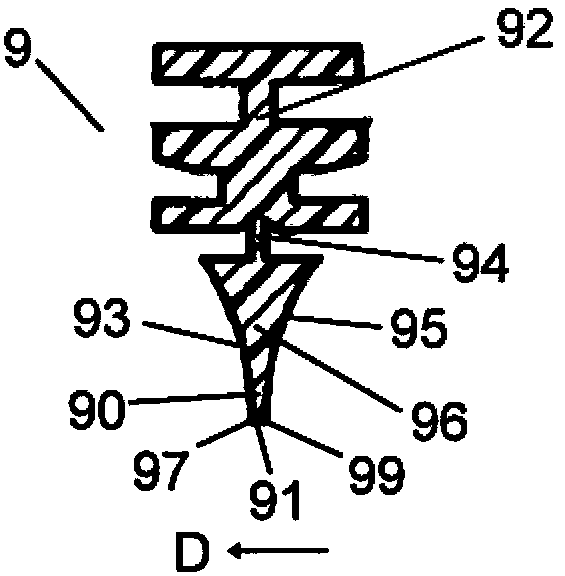

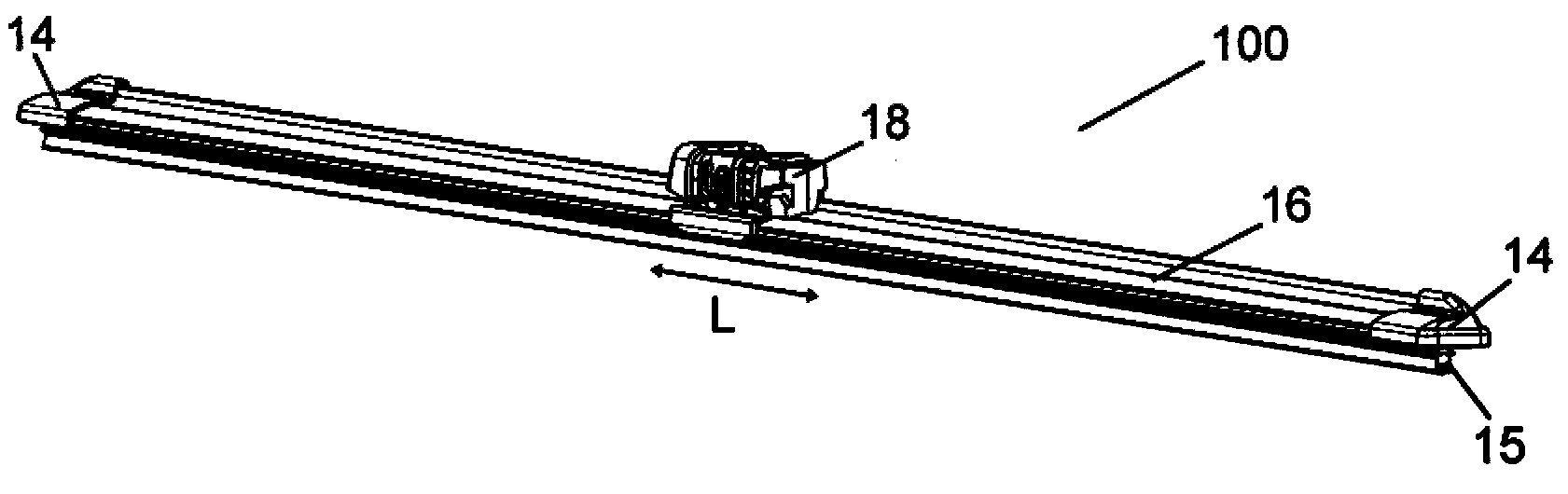

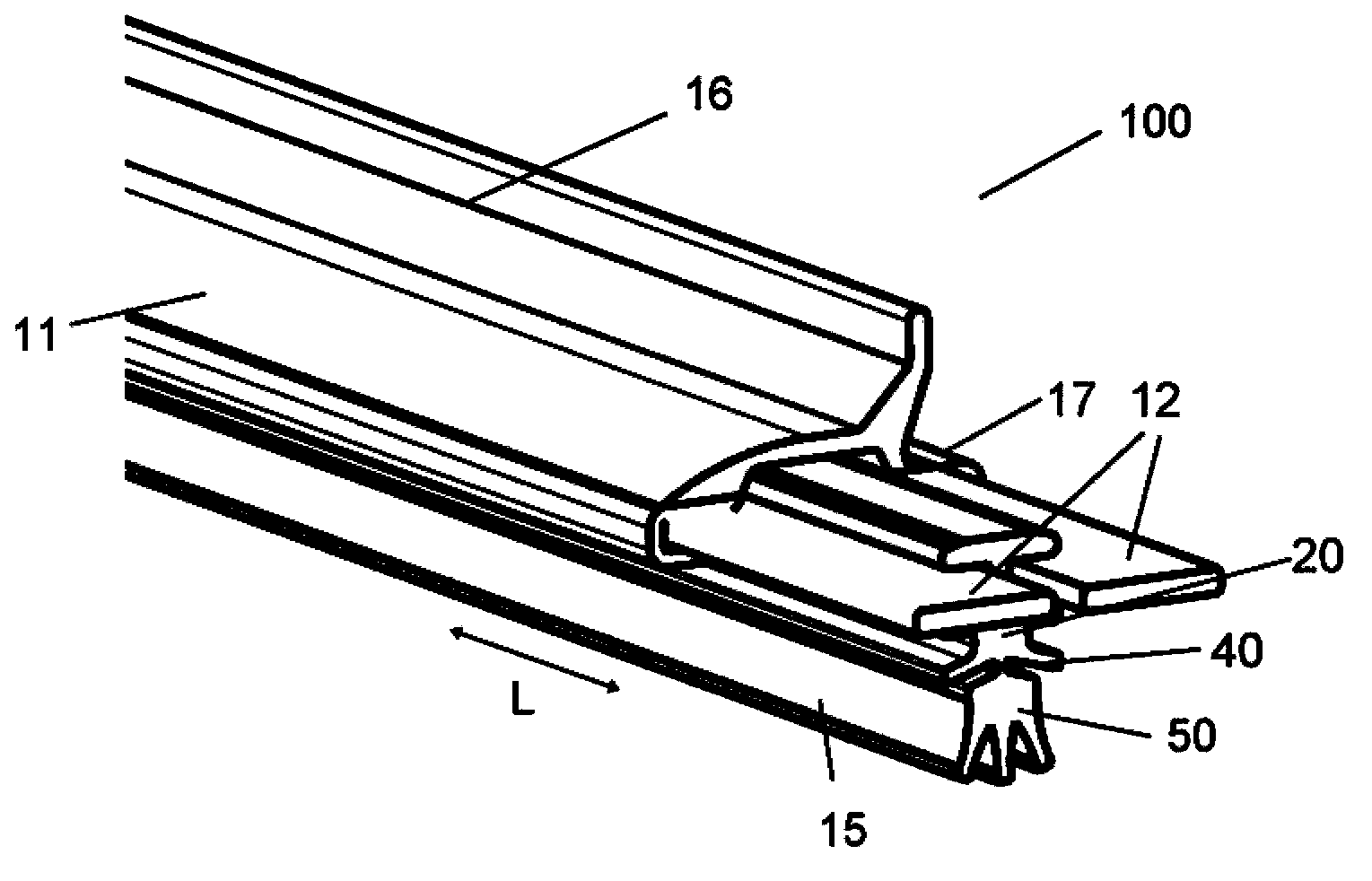

[0034] The wiper system according to the present invention is suitable for domestic or commercial vehicles, such as passenger cars, trucks, trams and the like.

[0035] The wiper system includes a wiper blade assembly, and the wiper blade assembly directly acts on the windshield of the vehicle through rubber parts. High-quality rubber parts must have the characteristics of cold and heat resistance, corrosion resistance, fit the windshield, reduce the load on the motor, low noise, strong water repellency, soft and not scratch the windshield, etc., so as to enable the driver to obtain a clear vision Purpose.

[0036] Generally, the rubber part of the wiper blade assembly can be selected from natural rubber or artificial synthetic rubber, which can be formed by molding or extrusion. Optionally, in order to reduce the friction between the rubber parts of the wiper system and the windshield, a lubricating coating can be applied to at least the part of the rubber parts in contact w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com