Three-dimensional tubular loom

A tubular loom technology, applied in looms, textiles, textiles and papermaking, etc., can solve problems such as the difficulty in realizing continuous weaving process automation of weft insertion, and achieve simple and easy mechanization and automation, wide designability, The effect of strong fabric structure diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

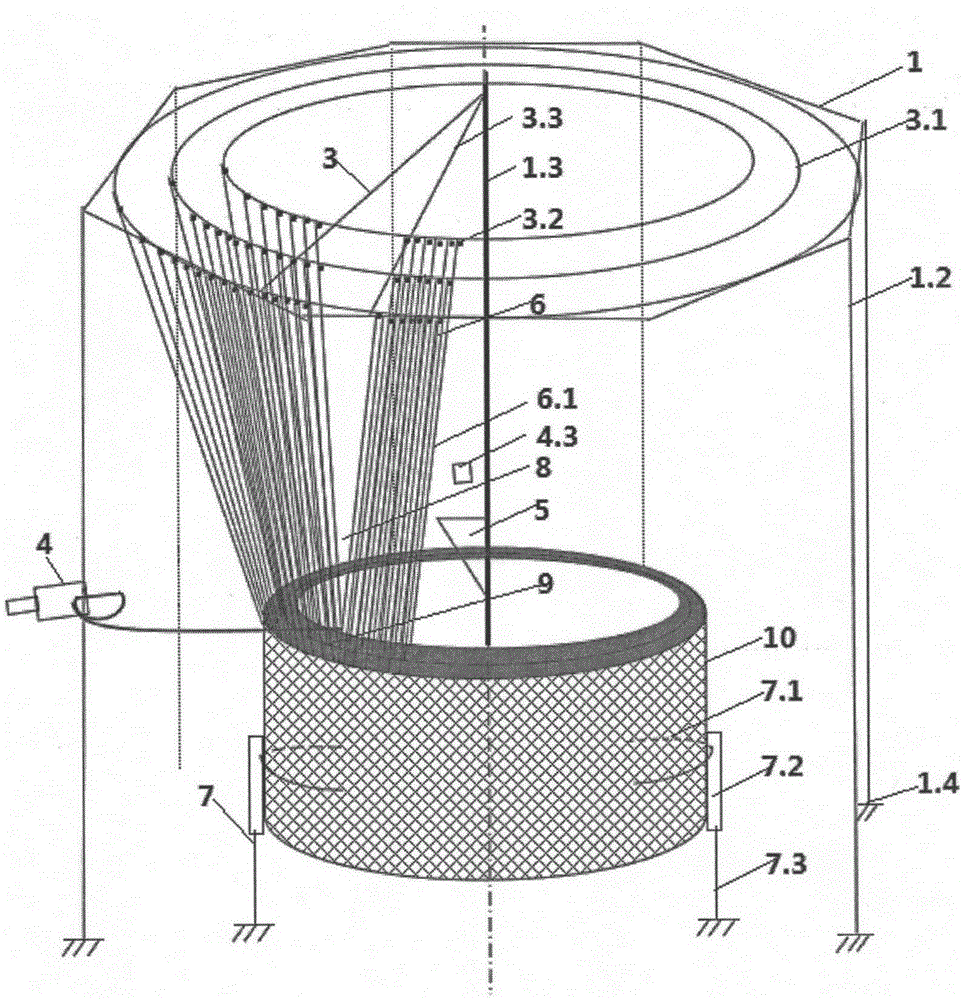

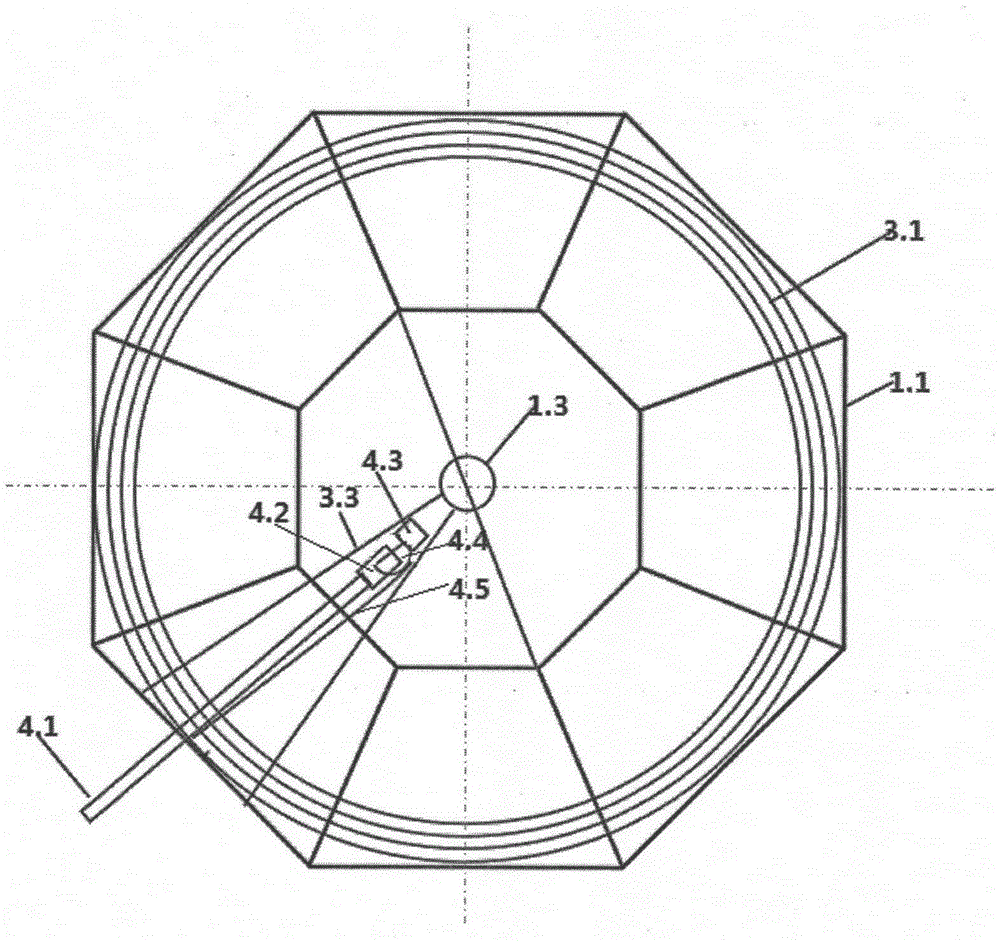

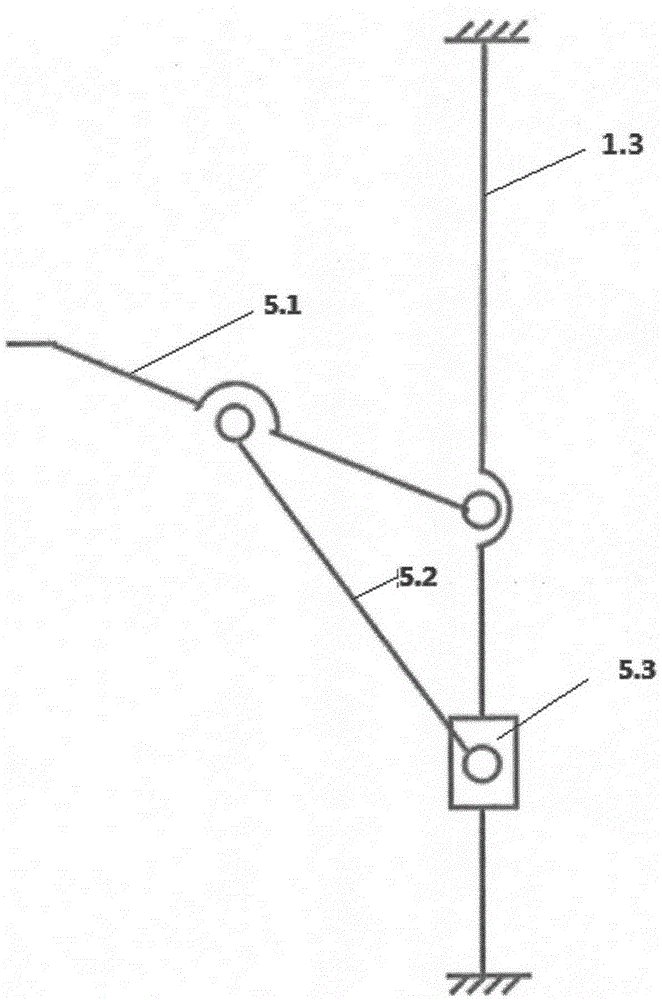

[0020] Such as Figure 1-4 Shown is a schematic diagram of the structure of the three-dimensional cylindrical loom provided by the present invention. It includes a frame 1, a transmission mechanism, a circumferential shedding mechanism 3, a radial weft insertion mechanism 4, an axial beating-up mechanism 5, and a yarn storage type feeding mechanism. After the device 6 and the linear winding mechanism 7.

[0021] Frame 1 consists of frame top 1.1, bracket 1.2, pole 1.3 and base 1.4. The material is ordinary carbon steel. The frame top 1.1 is designed as an octagon. The diameter of the outer octagonal inscribed circle is 200cm. The pole 1.3 is located on the machine. The center of the frame 1.

[0022] The circumferential opening mechanism 3 is composed of a circular rail 3.1, a sliding block 3.2 and a distribution device 3.3. The circular rail 3.1 is fixed on the top of the rack 1.1. The circular rail 3.1 is an I-shaped and made of aluminum alloy. There are three Orbital ring; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com