Rod-shaped workpiece holder

A workpiece fixture and rod-shaped technology, applied in the field of rod-shaped workpiece fixtures, can solve the problems of low processing efficiency, unsatisfactory effect, inconvenient replacement of workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

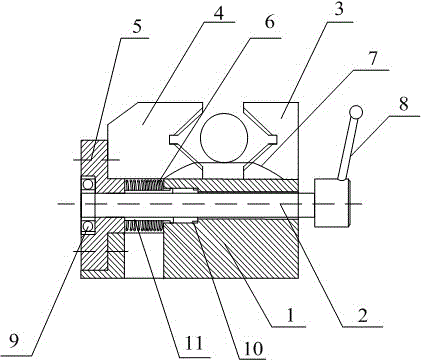

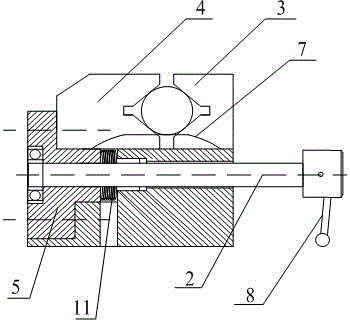

[0011] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

[0012] Such as figure 1 with figure 2 The shown rod-shaped workpiece fixture includes a base 1, a power rod 2, and jaws. The jaws are composed of a movable jaw 4 and a static jaw 3. The static jaw 3 is fixed on the upper surface of the base 1. The movable jaw 4 and the static jaw 3 are arranged horizontally opposite each other, and the movable jaw 4 is fixedly connected by a slide block 5 sliding on the base 1, and the slide block 5 is connected with one end of the power rod 2 through a bearing 9. The other end of the power rod 2 is fixedly connected with a joystick 8, the power rod 2 slides horizontally in the base 1, and a forming cavity of 5 cm is formed between the slide block 5 and the base 1, and the power rod 2 is formed on the base 1. A spring 6 is sleeved at the position of the cavity, and the selection of the spring 6 is not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com