Plastifying process for calendering type grass green rubber foxing rubber for liberation shoes

A kind of technology of rubber enclosing glue and rolling type, which is applied in the plasticating process field of calendered grass-green rubber enclosing glue for Jiefang shoes, which can solve the problems of low safety, large fluctuation of plasticity, high labor intensity, etc., and achieve production High efficiency, low energy cost and less dust flying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

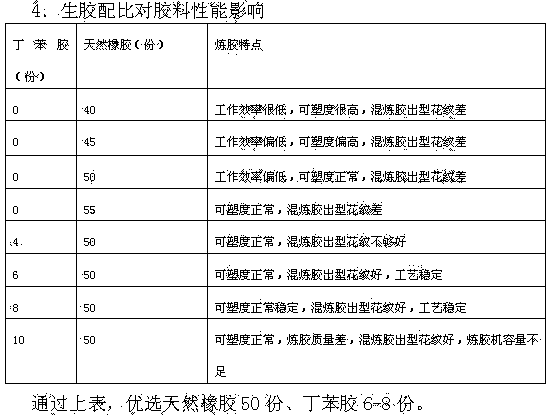

[0017] Embodiment 1 of the present invention: the masticating process of calendered grass-green rubber enclosure glue for Jiefang shoes, calculated according to parts by weight, 4.5 kilograms of styrene-butadiene rubber, 30 kilograms of natural rubber, 0.3 kilogram of anti-aging agent KY-405L, composite resin DS-B 2.4 kg, and peptizer DS-T-1 0.3 kg; cut the natural rubber into 10-15 kg / block rubber blocks, put 5 kg of cut natural rubber into the internal mixer, and wrap the roll , then put in composite resin DS-B and peptizer DS-T-1, after banburying for 3 minutes, add anti-aging agent KY-405L, and refine until the anti-aging agent KY-405L is evenly dispersed; then add styrene-butadiene rubber and the remaining natural Rubber, after 3 minutes of internal mixing, discharge the material to obtain the internal mixing rubber; put the internal mixing rubber into the open rubber mixing machine, under the roller distance of 0.5 ~ 1mm, open the knife and turn it off the machine for 7 t...

Embodiment 2

[0018] Embodiment 2 of the present invention: the plasticizing process of calendered grass-green rubber enclosing strip glue for Jiefang shoes, calculated according to parts by weight, 4 kilograms of styrene-butadiene rubber, 35 kilograms of natural rubber, 0.2 kilogram of anti-aging agent KY-405L, composite resin 2 kg of DS-B, and 0.2 kg of peptizer DS-T-1; cut the natural rubber into 10-15 kg / block rubber blocks, put 4 kg of cut natural rubber into the internal mixer, and wrap the roll , then put in composite resin DS-B and peptizer DS-T-1, after banburying for 3 minutes, add anti-aging agent KY-405L, and refine until the anti-aging agent KY-405L is evenly dispersed; then add styrene-butadiene rubber and the remaining natural Rubber, after 3 minutes of internal mixing, discharge the material to obtain the internal mixing rubber; put the internal mixing rubber into the open rubber mixing machine, under the roller distance of 0.5 ~ 1mm, open the knife and turn it off the machin...

Embodiment 3

[0019] Embodiment 3 of the present invention: the plasticizing process of calendered grass-green rubber wrap glue for Jiefang shoes, calculated according to parts by weight, 5 kilograms of styrene-butadiene rubber, 25 kilograms of natural rubber, 0.4 kilogram of anti-aging agent KY-405L, composite resin 3 kg of DS-B, and 0.4 kg of peptizer DS-T-1; cut the natural rubber into 10-15 kg / block rubber blocks, put 6 kg of cut natural rubber into the internal mixer, and wrap the roll , then put in composite resin DS-B and peptizer DS-T-1, after banburying for 3 minutes, add anti-aging agent KY-405L, and refine until the anti-aging agent KY-405L is evenly dispersed; then add styrene-butadiene rubber and the remaining natural Rubber, after 3 minutes of internal mixing, discharge the material to obtain the internal mixing rubber; put the internal mixing rubber into the open rubber mixing machine, under the roller distance of 0.5 ~ 1mm, open the knife and turn it off the machine for 8 tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com