Modification of natural fibers for anionically polymerized nylon 6 reaction processing

An anionic polymerization and natural fiber technology, which is applied in fiber treatment, plant fiber, dry-cleaning fiber products, etc., can solve problems such as hindering polymerization, and achieve the effects of reducing impact, improving strength and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

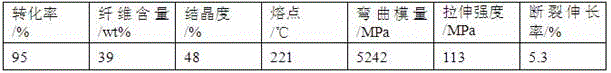

Embodiment 1

[0034] 50g ramie fiber fabric is selected, and the structural parameters are 21s×21s, 52×36. Firstly, it is pretreated to remove impurities such as colloid, grease, polyvinyl alcohol, and ash contained therein. Dissolve sodium hydroxide, sodium dodecylbenzenesulfonate and sodium carbonate in deionized water at 2g / L, 3% and 2% respectively and stir evenly, then add natural fiber at a weight ratio of 1:50, heat up To 95 ℃, under stirring for 4h;

[0035] Then, the cleaned natural fibers were first dried in a blast drying oven at 60°C for 8 hours, and finally dried in a freeze dryer at a temperature of -45°C and a vacuum of 9Pa for 24 hours.

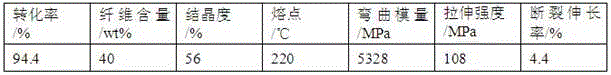

Embodiment 2

[0037] Select 20g ramie fiber bundles for use and cut into short fibers. It is cleaned by placing it in a specially configured solution consisting of deionized water, sodium dodecylbenzenesulfonate (3%) and sodium carbonate (2%), and then adding it in a weight ratio of 1:50 For natural fibers, heat up to 40 °C and process for 5 hours under stirring;

[0038] Then, the cleaned natural fibers were first dried in a blast drying oven at 60°C for 8 hours, and finally dried in a freeze dryer at a temperature of -45°C and a vacuum of 9Pa for 24 hours.

Embodiment 3

[0040] The fibers initially modified in Example 1 were placed in a coupling agent solution of a specific concentration for further modification, the water / ethanol volume ratio was 1:3, the dilution concentration of the coupling agent was 0.1%, and the dosage of the silane coupling agent was: 2wt%; slowly add ammonia water with a concentration of 5%, and adjust the pH value to between 8 and 10; add 50g of natural fiber fabric, after ultrasonic treatment for 1h, transfer to 80°C oil bath for reflux reaction for 6hr, and pass N2 gas protection; after the reaction, take out the fiber and wash it with 85% ethanol solution to remove the unreacted KH550; put the washed natural fiber in a blast drying oven at 60°C for 6-8 hours, and then put it in Dry for 24 hours in a freeze dryer with a temperature of -45°C and a vacuum of 9 Pa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com