Method and device for measuring pipeline end face central points

A center point and end face technology, which is applied to the measurement field of the center point of the pipe end face, can solve the problems of difficult to guarantee measurement accuracy, affect the geometric center accuracy, low measurement efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

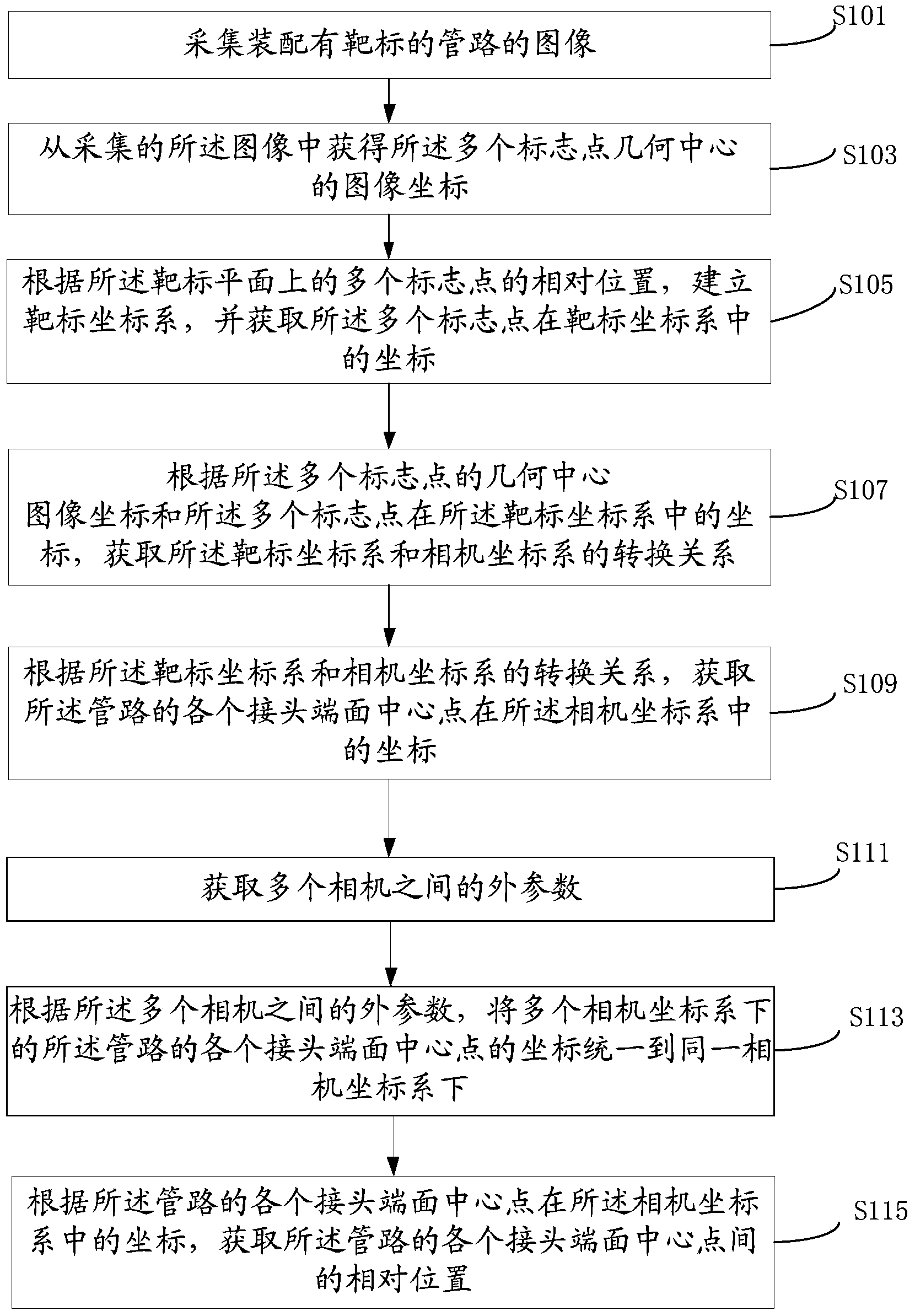

[0076] According to an aspect of an embodiment of the present invention, a method for measuring the center point of a pipeline end surface is provided, such as figure 1 As shown, the method includes:

[0077] Step S101 , collecting an image of a pipeline equipped with a target.

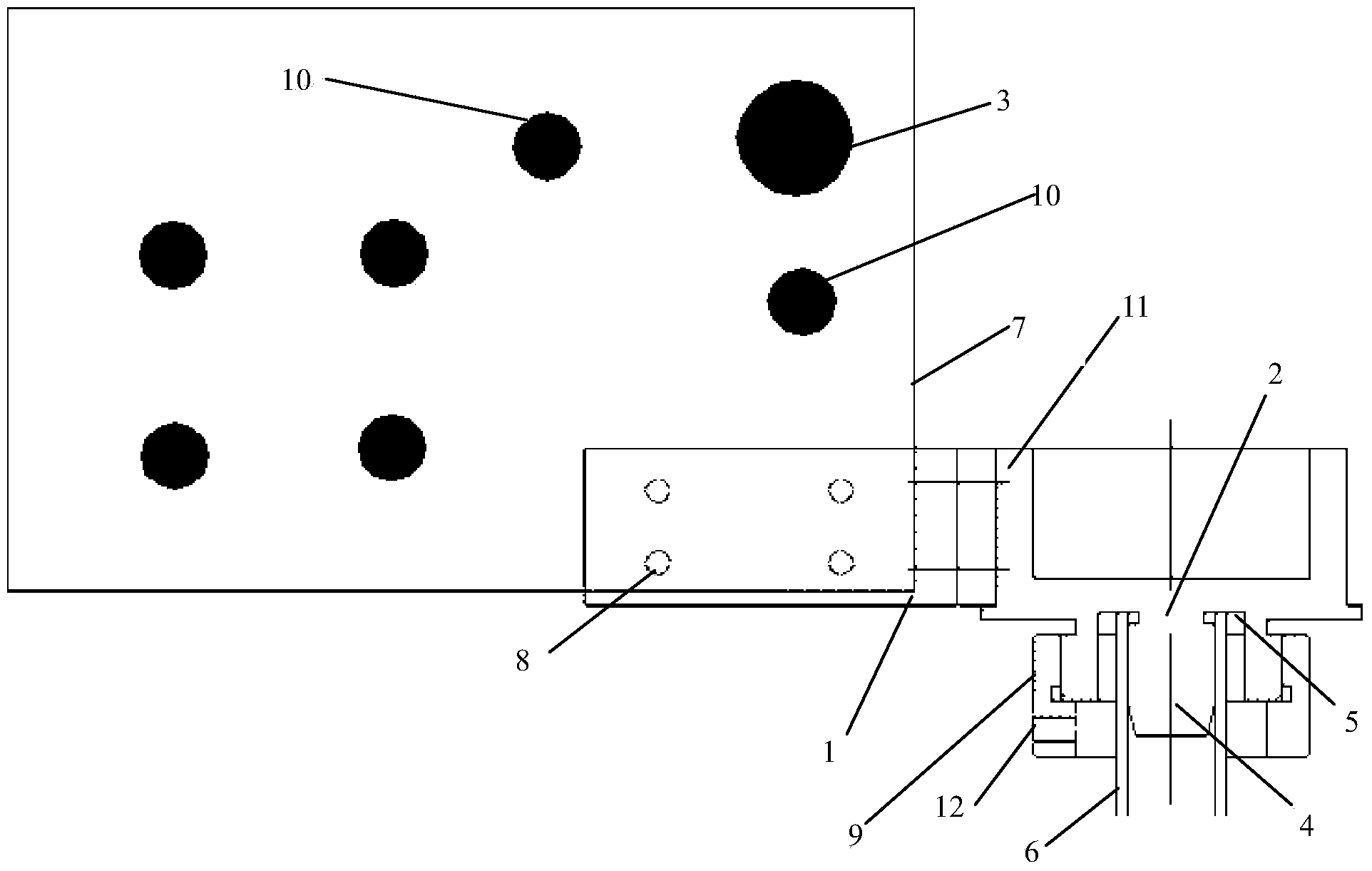

[0078] Before measuring the center point of the end face of the pipe, the target needs to be assembled on the pipe joint. Such as figure 2 As shown, a plurality of marking points are arranged on the target plane 7 of the target, and the target plane can be plexiglass, and is fixed on the target by a fixing part 8 . Seven mark points are set on the target plane 7 in the embodiment of the present invention. Wherein, a plurality of mark points include a large mark point 3 and a plurality of small mark points 10, the large mark point 3 is used to determine the origin of the target coordinate system, and the multiple small mark points 10 are used to determine the The coordinate axis direction of the t...

Embodiment 2

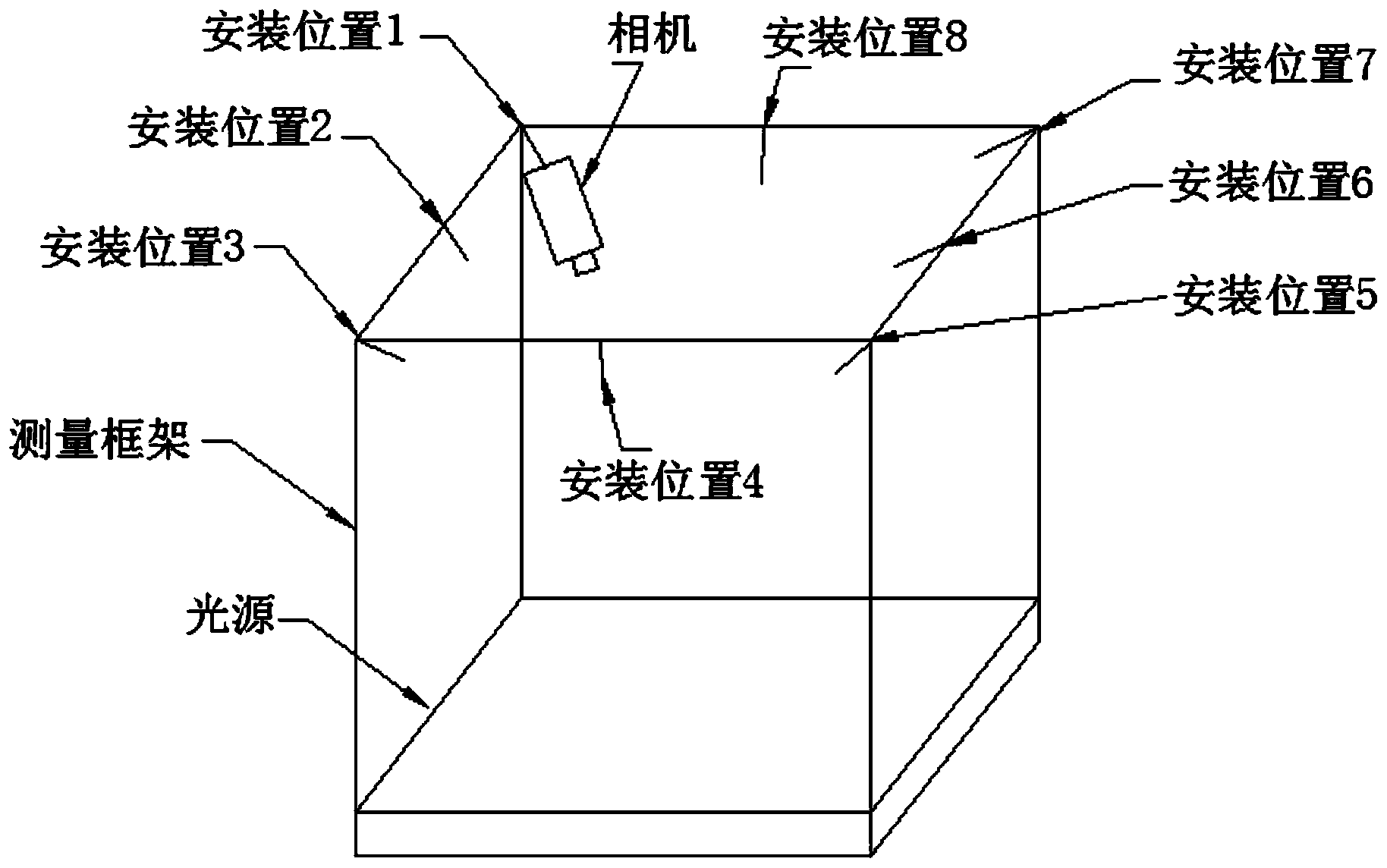

[0114] According to another aspect of the present invention, there is also provided a measuring device 400 for the center point of the pipeline end surface, such as Figure 4 As shown, the device includes:

[0115] An image acquisition module 401, configured to acquire an image of a pipeline equipped with a target, where a plurality of marker points are set on the target plane;

[0116] An image coordinate acquisition module 403, configured to obtain the image coordinates of the geometric centers of the plurality of marker points from the collected images;

[0117] A target coordinate system establishment module 405, configured to establish a target coordinate system according to the relative positions of the multiple marker points on the target plane, and obtain the coordinates of the multiple marker points in the target coordinate system;

[0118] The conversion relationship acquisition module 407 is configured to acquire the conversion relationship between the target coord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com