System and method for testing lateral resistance of roadbed of ladder track

A technology of lateral resistance and testing system, which is applied in the field of rail transit, can solve the problems of insufficient applicability of the lateral force method and device, and does not meet the longitudinal structure of ladder-type sleepers, etc., and achieve the effect of large reaction force value, simple installation and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

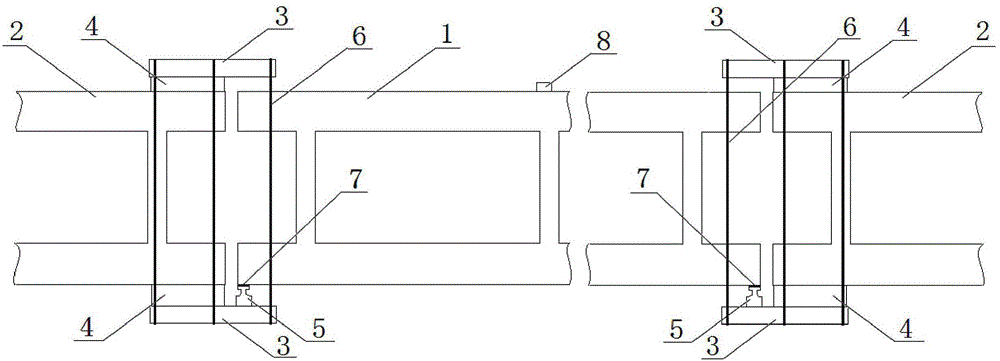

[0028] combine figure 1 The present invention is described further:

[0029] A ladder-type ballasted track bed lateral resistance testing system, one end of a sleeper 1 to be tested, and a square log 4 and a steel block 3 are arranged opposite to each other on both sides. The steel block 3 can be a rectangular steel block, or a cut section of scrap steel rail. The square wood 4 is placed close to the outside of the end of the sleeper 2 adjacent to the sleeper 1 to be tested, and the steel block 3 is placed close to the outside of the square wood 4 . The steel block 3 is longer than the square wood 4, and the part extending from the square wood 4 extends to the outside of the sleeper 1 to be tested, forming a suspended space with the end of the sleeper 1 to be tested. Between the steel blocks 3 on both sides of the same end, a steel wire rope 6 is sheathed, and its effect is to tightly fix the steel blocks 3 on both sides, the square wood 4 and the sleeper 2 together. As an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com