Ladder type track bed lateral resistance test system and test method

A technology of lateral resistance and testing system, which is applied in the field of rail transit, can solve the problems of not satisfying the longitudinal structural characteristics of ladder-type sleepers, insufficient applicability, lateral force method and device, etc., and achieve large reaction force value, simple installation and flexible operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

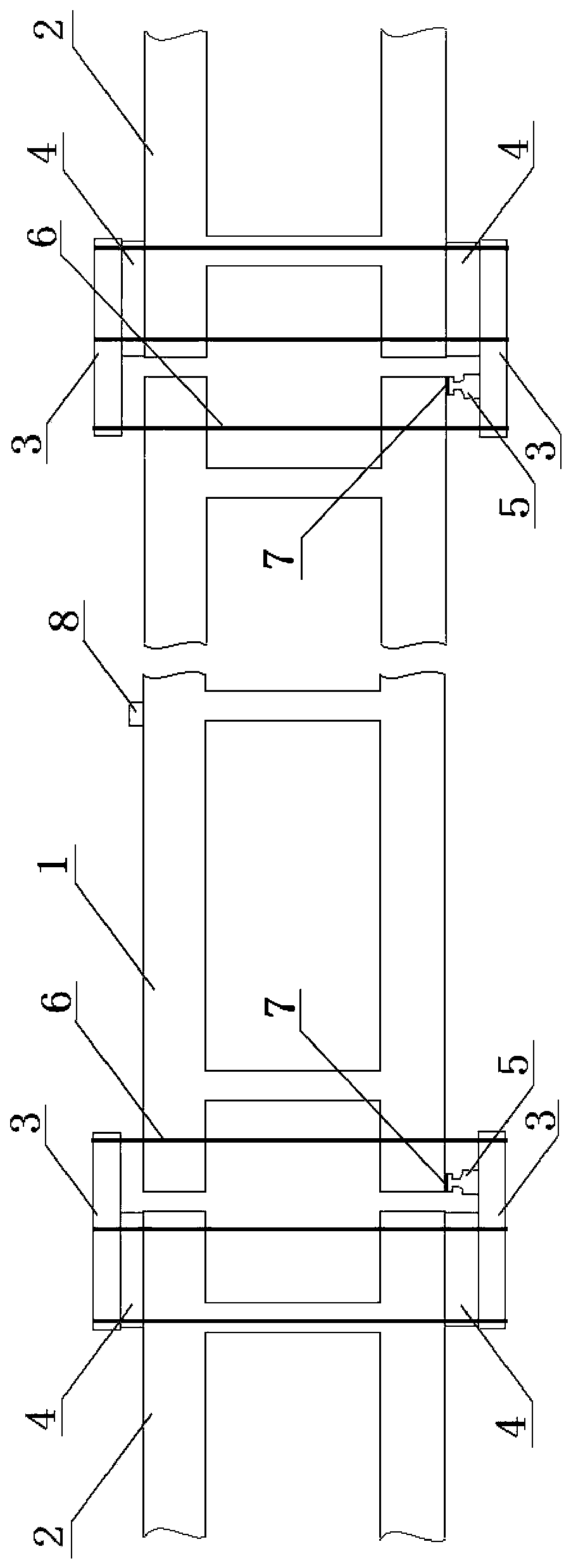

[0027] combine figure 1 The present invention is described further:

[0028] A ladder-type ballasted track bed lateral resistance testing system, one end of a sleeper 1 to be tested, and a square log 4 and a steel block 3 are arranged opposite to each other on both sides. The steel block 3 can be a rectangular steel block, or a cut section of scrap steel rail. The square wood 4 is placed close to the outside of the end of the sleeper 2 adjacent to the sleeper 1 to be tested, and the steel block 3 is placed close to the outside of the square wood 4 . The steel block 3 is longer than the square wood 4, and the part extending from the square wood 4 extends to the outside of the sleeper 1 to be tested, forming a suspended space with the end of the sleeper 1 to be tested. Between the steel blocks 3 on both sides of the same end, a steel wire rope 6 is sheathed, and its effect is to tightly fix the steel blocks 3 on both sides, the square wood 4 and the sleeper 2 together. As an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com